Liquid centrifugal nozzle with hydrophobic coating and manufacturing method thereof

A technology of hydrophobic coating and centrifugal nozzle, which is applied in spraying devices with movable outlets, devices for coating liquid on the surface, coatings, etc., to achieve the effects of reducing processing difficulty, stabilizing mechanical structure, and improving atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The following is based on Figure 1-8 A liquid centrifugal nozzle with a hydrophobic coating and its manufacturing method in the embodiment of the present invention are described in detail.

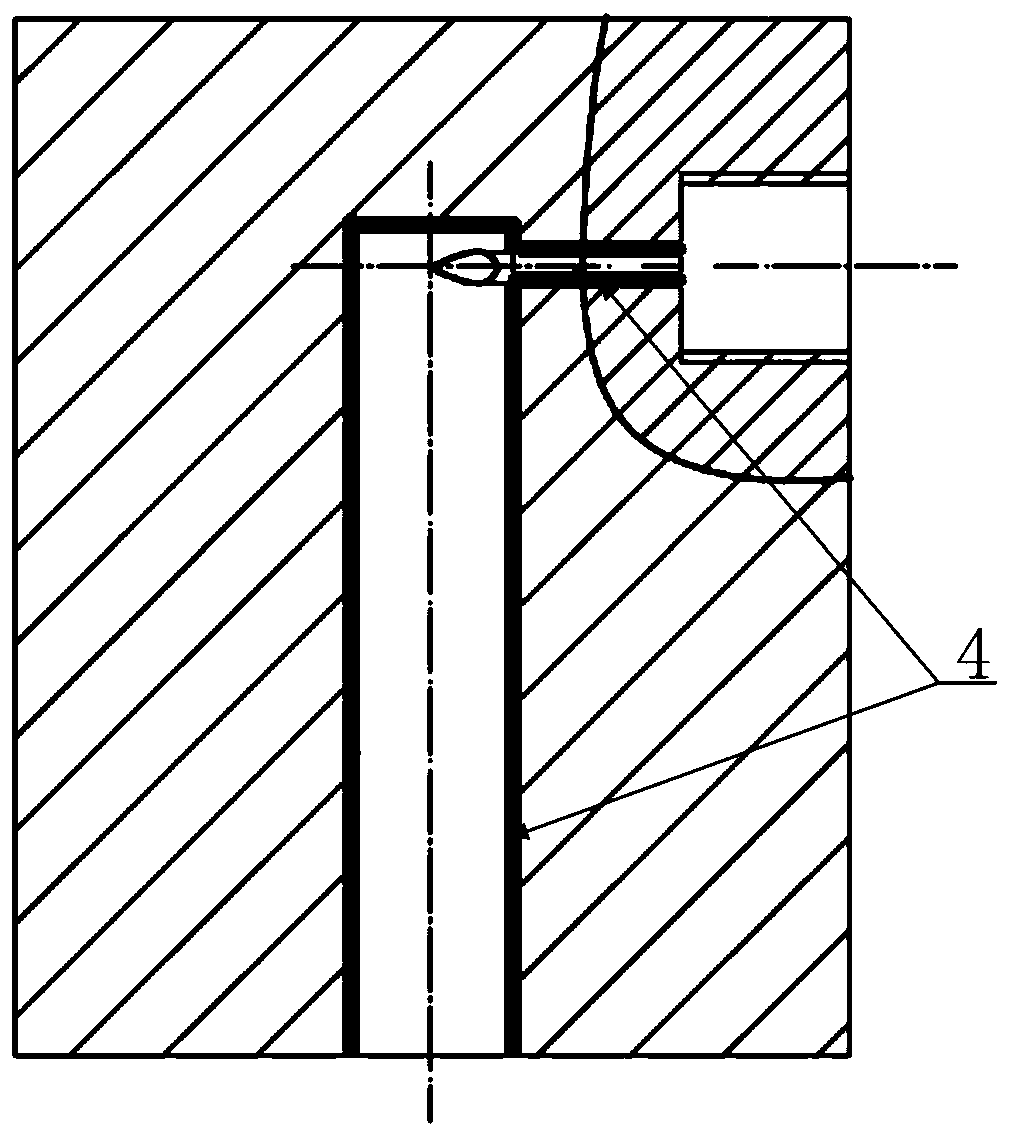

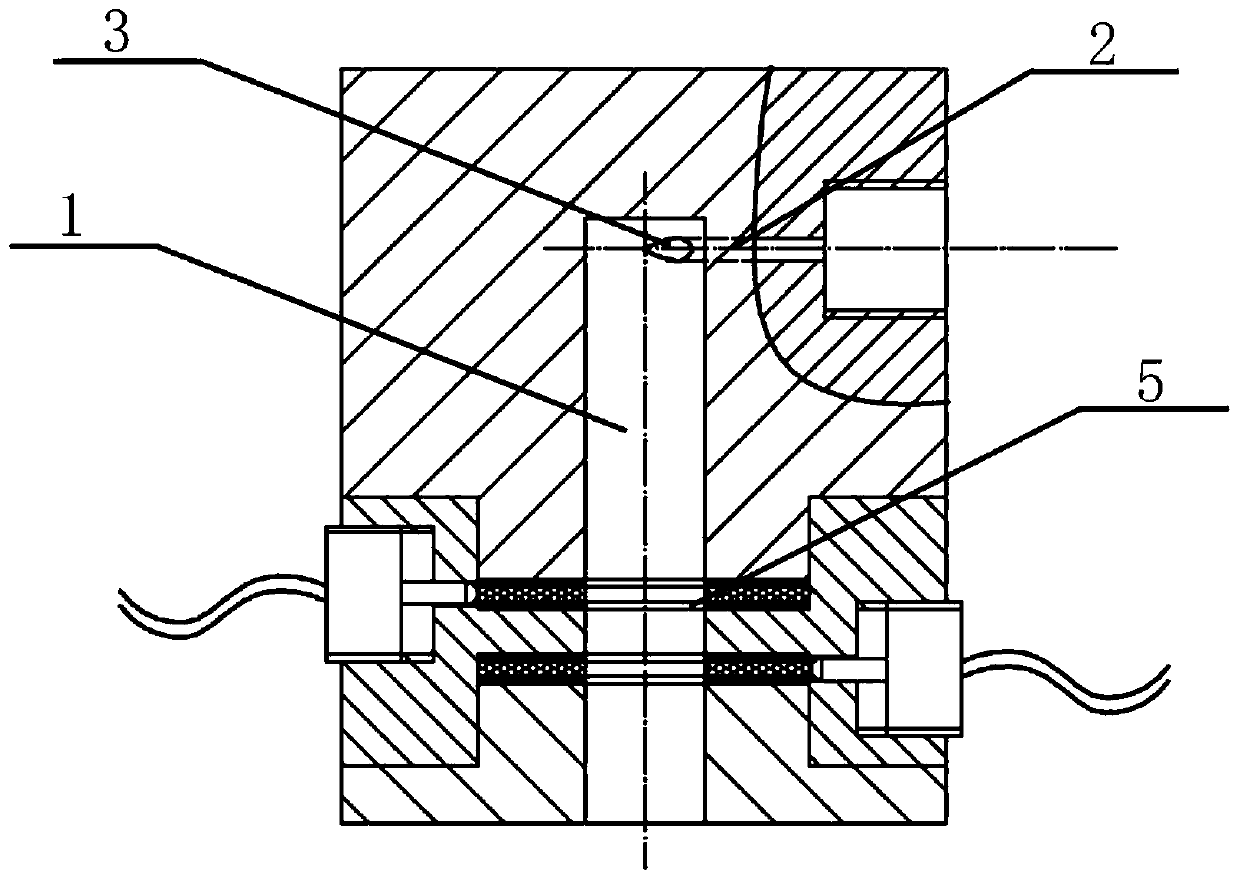

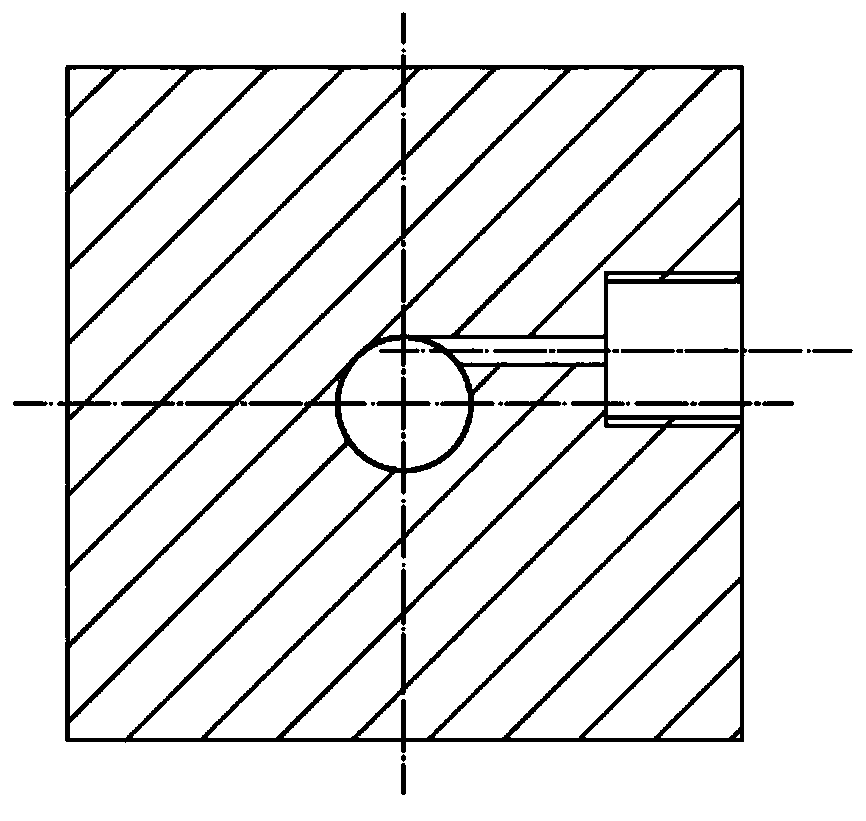

[0043] On the one hand, if Figure 1-3 As shown, the embodiment of the present invention discloses a liquid centrifugal nozzle with a hydrophobic coating, including: a swirl chamber 1, a tangential channel 2 is arranged on the head of the swirl chamber 1, and the inlet of the tangential channel 2 is connected to a flow supply system, the outlet of the tangential channel 2 corresponds to the inlet 3 of the swirl chamber; the inner walls of the tangential channel 2 and the swirl chamber 1 are coated with a hydrophobic coating 4 .

[0044] Further, a liquid film thickness measurement device is also provided on the swirl chamber 1; the liquid film thickness measurement device is preferably a ring electrode 5 arranged around the swirl chamber 1 and the ring electrode 5 adopts a double ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com