Animal protein modified water treating agent and preparation method and application thereof

A technology of animal protein and treatment agent, which is applied in the direction of protein coating, coating, polyurea/polyurethane coating, etc., which can solve the problems of affecting processing performance, PVC artificial leather material atomization performance, and easy volatilization, so as to improve atomization performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

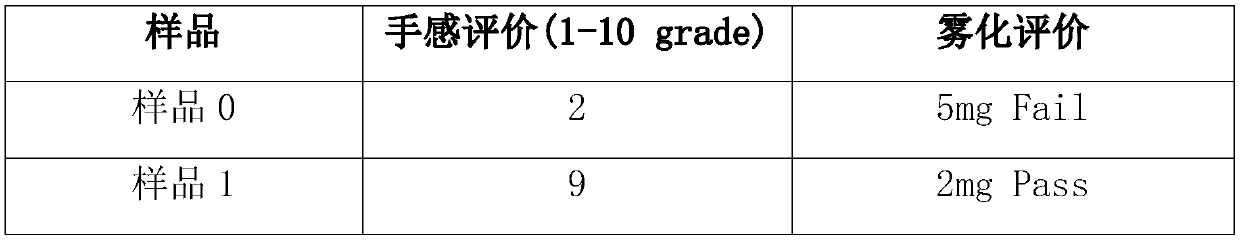

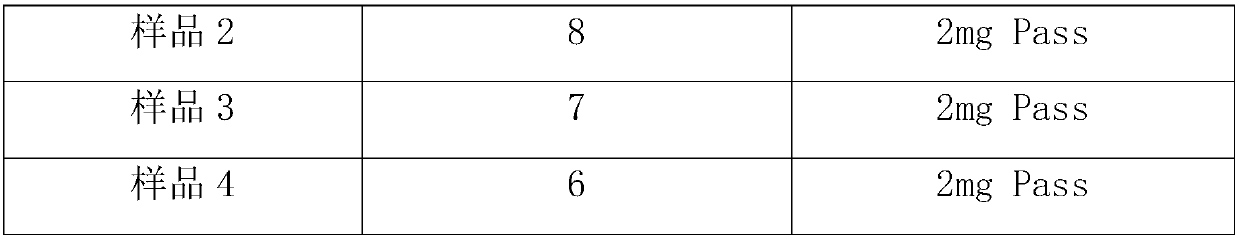

Examples

Embodiment 1

[0020] Embodiment 1: a kind of animal protein modified water treatment agent, its formula is: polycarbonate type polyurethane 70phr, nano silk fibroin protein powder 25phr, long-chain aliphatic alkyl sulfate sodium salt 3phr, light stabilizer 0.2phr, Joint agent 3phr, deionized water 100phr.

[0021] Adopt animal protein modified water treatment agent to prepare the method for PVC artificial leather:

[0022] Step 1: Material premixing: polycarbonate polyurethane 70phr, nano silk fibroin powder 25phr, long-chain aliphatic alkyl sulfate sodium salt 3phr, light stabilizer 0.2phr, crosslinking agent 3phr, deionized water 100phr. Complete the premixing of the water-based slurry according to the formula, stir at high speed for 0.5 hours after adding, fully disperse, and form a stable emulsion system.

[0023] Step 2: Printing: use the prepared protein treatment agent to surface treat the PVC semi-finished product prepared by the coating method, and dry it under the set process con...

Embodiment 2

[0026] Embodiment 2: a kind of animal protein modified water treatment agent, its formula is: polycarbonate type polyurethane 80phr, nano silk fibroin protein powder 20phr, long-chain aliphatic alkyl sulfate sodium salt 4phr, light stabilizer 0.3phr, Joint agent 4phr, deionized water 100phr.

[0027] Adopt animal protein modified water treatment agent to prepare the method for PVC artificial leather:

[0028] Step 1: Material premixing: polycarbonate polyurethane 80phr, nano silk fibroin powder 20phr, long-chain aliphatic alkyl sulfate sodium salt 4phr, light stabilizer 0.3phr, crosslinking agent 4phr, deionized water 100phr. Complete the premixing of the water-based slurry according to the formula, stir at high speed for 0.5 hours after adding, fully disperse, and form a stable emulsion system.

[0029] Step 2: Printing: use the prepared protein treatment agent to surface treat the PVC semi-finished product prepared by the coating method, and dry it under the set process con...

Embodiment 3

[0032] Embodiment 3: a kind of animal protein modified water treatment agent, its formula is: polycarbonate type polyurethane 90phr, nano silk fibroin protein powder 15phr, long-chain aliphatic alkyl sulfate sodium salt 4phr, photostabilizer 0.3phr, cross-linking Joint agent 5phr, deionized water 100phr.

[0033] Adopt animal protein modified water treatment agent to prepare the method for PVC artificial leather:

[0034] Step 1: Material premixing: polycarbonate polyurethane 90phr, nano silk fibroin powder 15phr, long-chain aliphatic alkyl sulfate sodium salt 4phr, light stabilizer 0.3phr, crosslinking agent 5phr, deionized water 100phr. Complete the premixing of the water-based slurry according to the formula, stir at high speed for 0.5 hours after adding, fully disperse, and form a stable emulsion system.

[0035] Step 2: Printing: use the prepared protein treatment agent to surface treat the PVC semi-finished product prepared by the coating method, and dry it under the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com