Novel porous ceramic atomizing core production process

A technology of porous ceramics and production process, applied in ceramic products, tobacco, other household appliances, etc., can solve the problems of low porosity, increase ceramic development cycle, ceramic porosity and pore size mismatch, etc., to achieve stable atomization performance, The effect of improving development efficiency and simplifying the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

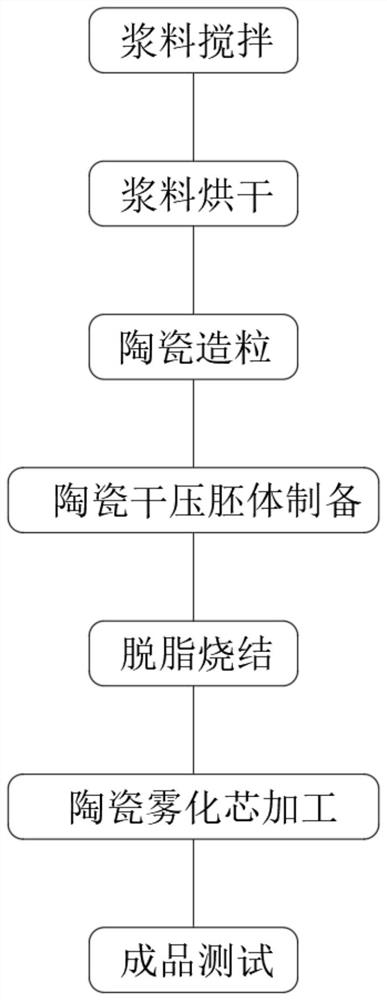

[0035] see Picture 1-1 , the present invention provides a technical solution: a novel porous ceramic atomizing core production process, comprising the following steps:

[0036] S1, slurry stirring

[0037] 80wt% SiO 2 , 12wt% Al 2 o 3 , 5 wt% Na 2 CO 3 , 1wt% CaCO 3 Powder and pore-forming powder are mixed with water. The pore-forming powder is graphite powder. The amount added is 40% of the total mass of SiO2, Al2O3, Na2CO3, and CaCO3, and a binder is added for stirring. During the stirring process, the pore-forming powder It is graphite, starch and plastic particles, and the amount added is 20% of the total mass of the powder.

[0039] After the stirred mixed slurry is taken out, it is uniformly dried to obtain a ceramic dry body.

[0040] S3, ceramic granulation

[0041] The dried ceramic dry body is evenly crushed, and the crushed ceramic dry body is evenly dispersed to obtain ceramic granulated powder.

[0042] S4. Preparation of cer...

Embodiment 2

[0053] see Picture 1-1 , the present invention provides a technical solution: a novel porous ceramic atomizing core production process, comprising the following steps:

[0054] S1, slurry stirring

[0055] 80wt% SiO 2 , 12wt% Al 2 o 3 , 5 wt% Na 2 CO 3 , 1wt% CaCO 3 Powder and pore-forming powder are mixed with water. The pore-forming powder is graphite powder. The amount added is 40% of the total mass of SiO2, Al2O3, Na2CO3, and CaCO3, and a binder is added for stirring. During the stirring process, the pore-forming powder It is graphite, starch and plastic particles, and the amount added is 20% of the total mass of the powder.

[0056] S2, slurry drying

[0057] After the stirred mixed slurry is taken out, it is uniformly dried to obtain a ceramic dry body.

[0058] S3, ceramic granulation

[0059] The dried ceramic dry body is evenly crushed, and the crushed ceramic dry body is evenly dispersed to obtain ceramic granulated powder.

[0060] S4. Preparation of ceram...

Embodiment 3

[0071] see Picture 1-1 , the present invention provides a technical solution: a novel porous ceramic atomizing core production process, comprising the following steps:

[0072] S1, slurry stirring

[0073] 80wt% SiO 2 , 12wt% Al 2 o 3 , 5 wt% Na 2 CO 3 , 1wt% CaCO 3 Powder and pore-forming powder are mixed with water. The pore-forming powder is graphite powder. The amount added is 40% of the total mass of SiO2, Al2O3, Na2CO3, and CaCO3, and a binder is added for stirring. During the stirring process, the pore-forming powder It is graphite, starch and plastic particles, and the amount added is 20% of the total mass of the powder.

[0074] S2, slurry drying

[0075] After the stirred mixed slurry is taken out, it is uniformly dried to obtain a ceramic dry body.

[0076] S3, ceramic granulation

[0077] The dried ceramic dry body is evenly crushed, and the crushed ceramic dry body is evenly dispersed to obtain ceramic granulated powder.

[0078] S4. Preparation of cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com