Pulverizer for plastic production

A pulverizer and pulverizing mechanism technology, applied in the field of plastics, can solve problems such as fusion of phenolic plastics, and achieve the effect of avoiding the phenomenon of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

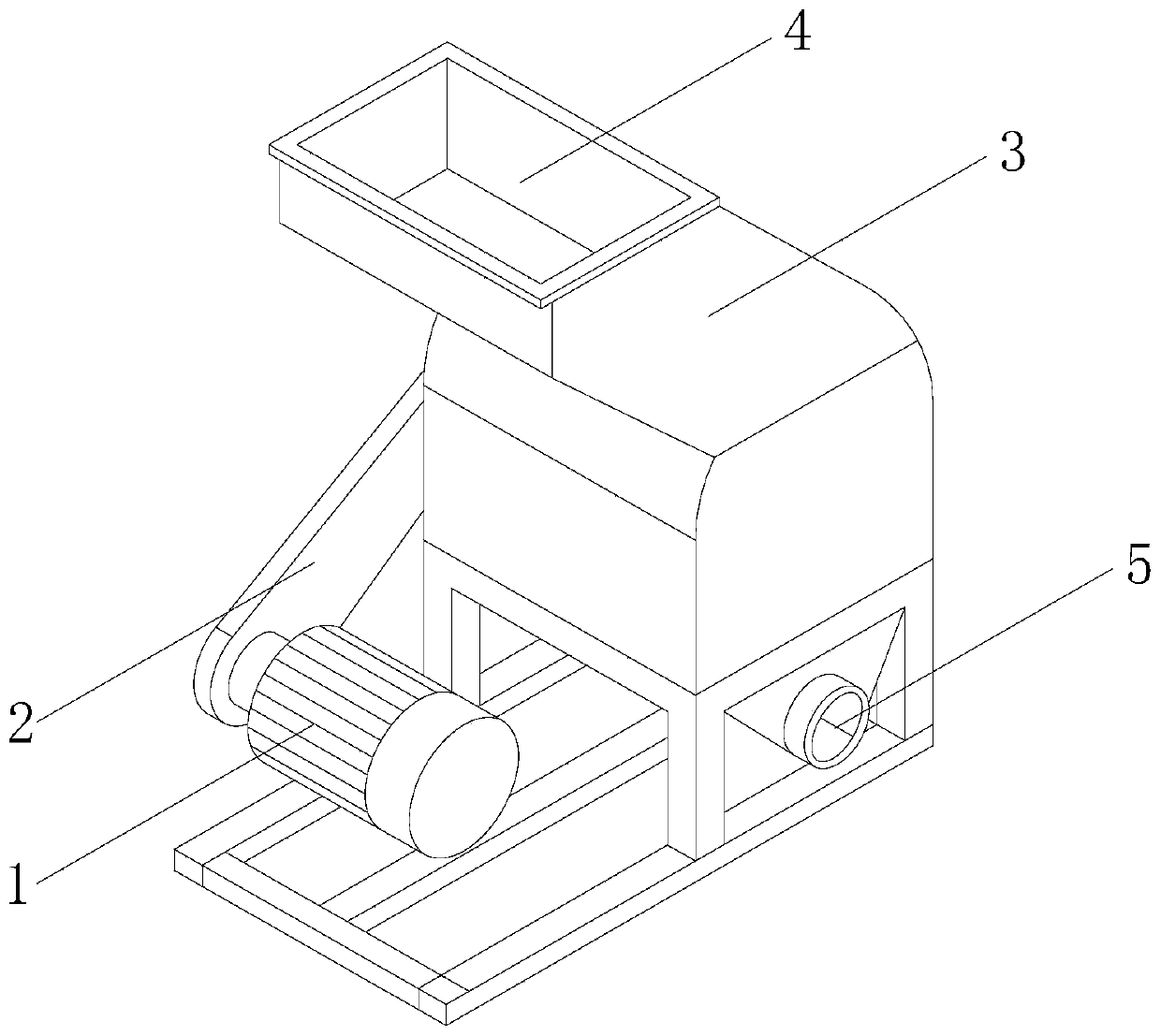

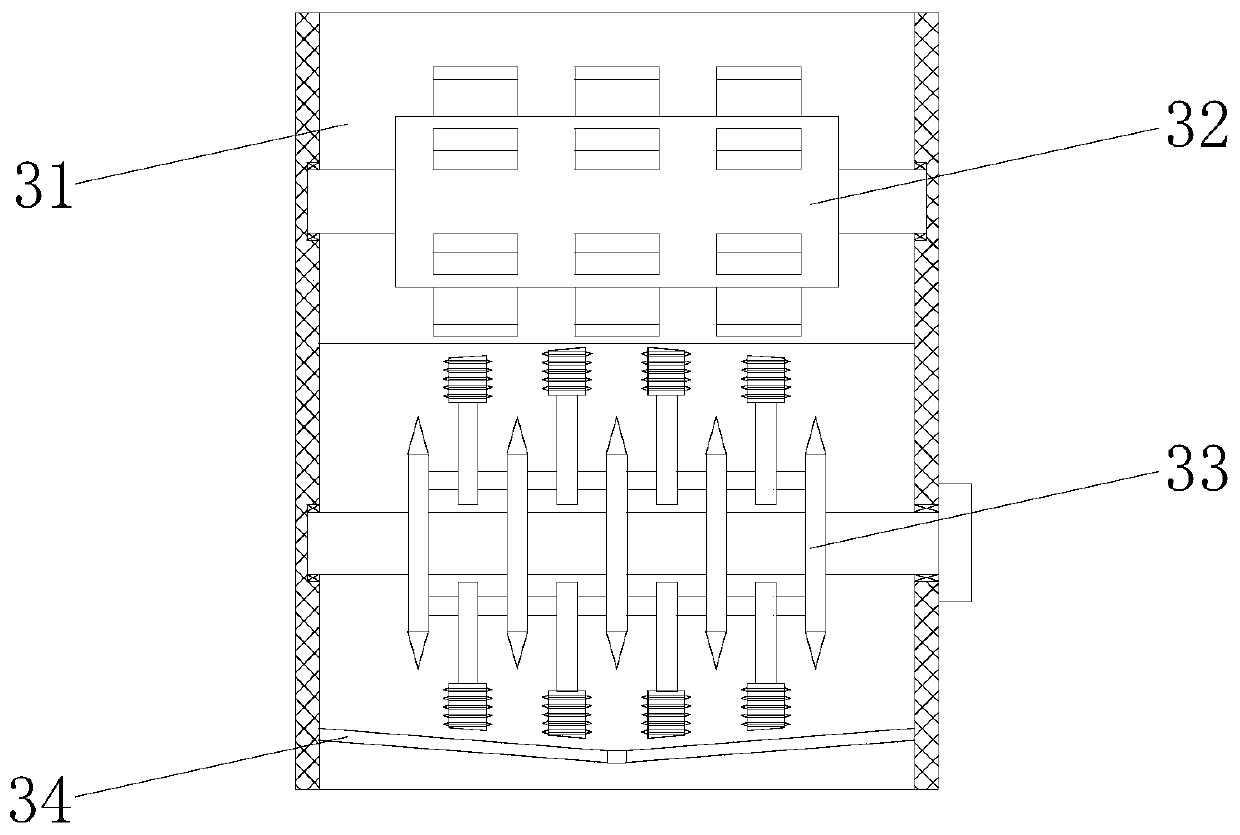

[0022] as attached figure 1 To attach Figure 5 Shown:

[0023] The present invention is a pulverizer for plastic production, which comprises a motor 1, a dust cover 2, a pulverizer body 3, a feed port 4, and a discharge port 5, and the output end of the motor 1 is installed inside the dust cover 2, so that The upper end of the dustproof cover 2 is installed outside the pulverizer body 3, the upper end of the pulverizer body 3 is fixedly installed with a feed port 4 and communicates with each other, and the lower end of the pulverizer body 3 is embedded with a discharge port 5 to communicate with each other. It includes a casing 31, a toggle mechanism 32, a crushing mechanism 33, and a cylinder wall 34. A toggle mechanism 32 is fixedly installed on the upper end of the casing 31. The toggle mechanism 32 is located at the lower end of the feeding port 4, and the crushing mechanism 33 is fixed. Installed at the lower end of the shell 31, the crushing mechanism 33 rotates synch...

Embodiment 2

[0030] as attached Figure 6 To attach Figure 7 Shown:

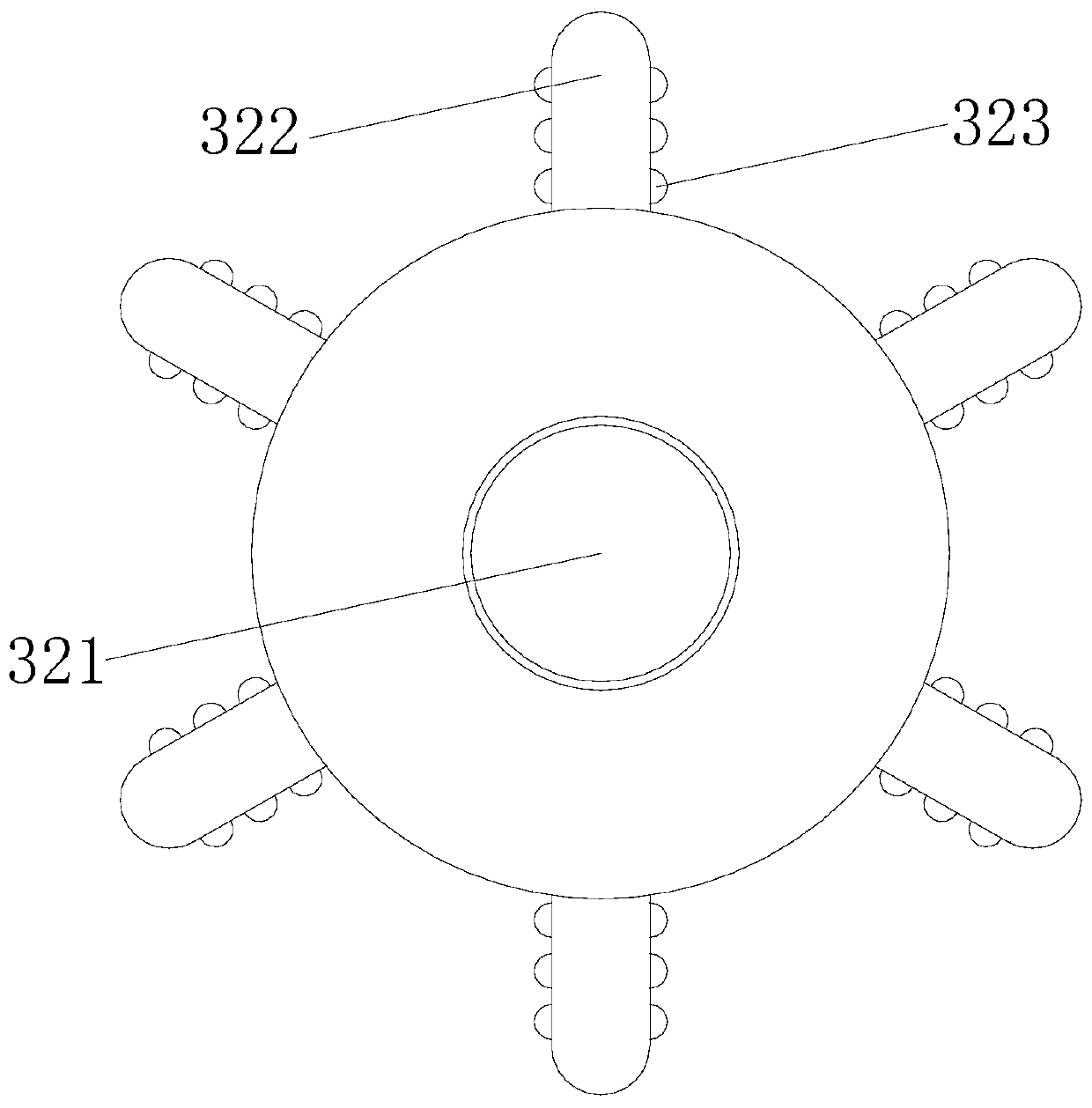

[0031] Wherein, the crushing mechanism 33 includes a rotating shaft 331, a moving knife 332, and a pendulum 333. The rotating shaft 331 rotates synchronously with the output end of the motor 1 through the belt provided inside the dust cover 2. The rotating shaft 331 It runs through the inside of the moving knife 332 and rotates synchronously. The outer wall of the moving knife 332 is fixed to the lower end of the pendulum 333. There are sixteen pendulums 333 in total, and four of them form a group. In four directions, it is beneficial to crush fine phenolic plastics.

[0032]Wherein, the pendulum 333 includes a swing rod 33a, a spring 33b, a knife edge 33c, and a hammer body 33d. 33b is fixed to the upper end of the swing rod 33a, and the upper end of the swing rod 33a is installed inside the hammer body 33d with clearance fit. The blade 33c is fixedly installed on the outside of the hammer body 33d. The inclination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com