Construction method for transversely moving and erecting steel plate composite beam

A construction method and technology of composite beams, which are applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as vertical hoisting, and achieve the effects of less auxiliary personnel, simple operation, fast and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

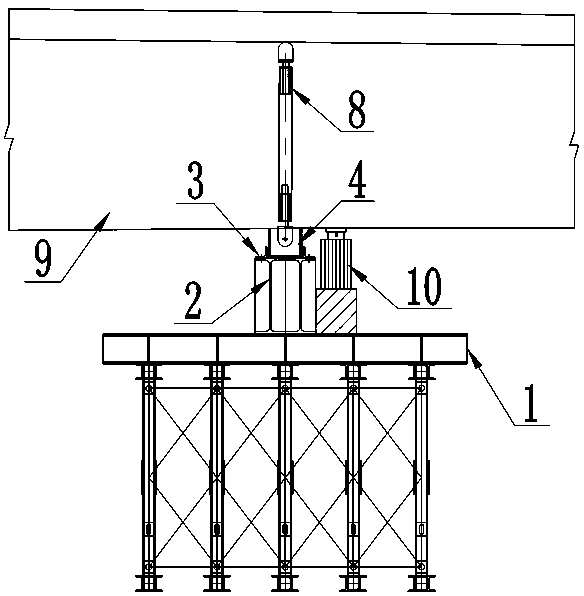

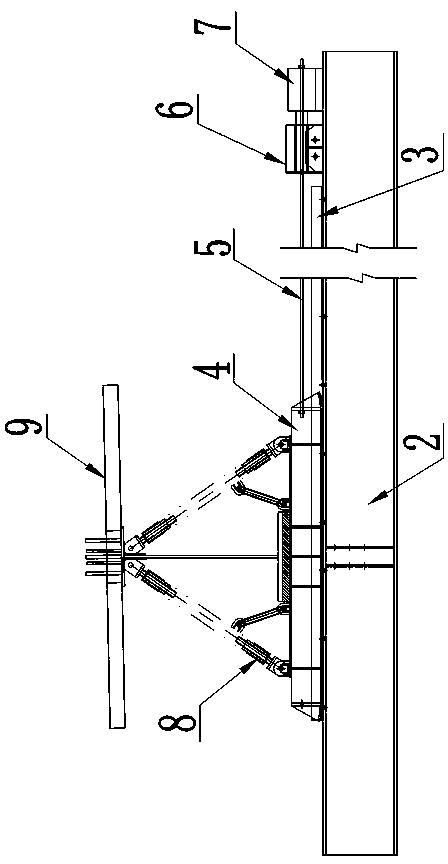

[0027] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0028] A construction method for laterally erecting steel plate composite beams, the central positioning of the bottom opening and the top opening of the steel pipe column includes the following steps:

[0029] A. First set up the temporary bracket for the beam body erection, set up bolt holes and hoisting holes on the bracket beam 1, install the chute 3 on the slideway beam 2, and the limit chute 3 is two limit angle steels, and the limit slide The groove 3 is fixed on the slideway beam 2 with bolts, then the slideway beam 2 is hoisted, the slideway beam 2 is installed on the support beam 1, and the slideway beam 2 and the support beam 1 are welded firmly;

[0030] B. Put the slider 4 in the limit chute 3, and fix the adjustable screw strut 8 with a steel pin on the slider 4, and the adjustable screw strut 8 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com