Nitrogen self-pressurization air separation device

An air separation unit and self-pressurization technology, which is applied in the direction of cold treatment separation, liquefaction, solidification, etc., can solve the problems of investment cost and operation cost increase, and achieve the effect of saving one-time investment, improving distillation efficiency and high profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical content of the present invention will be further described:

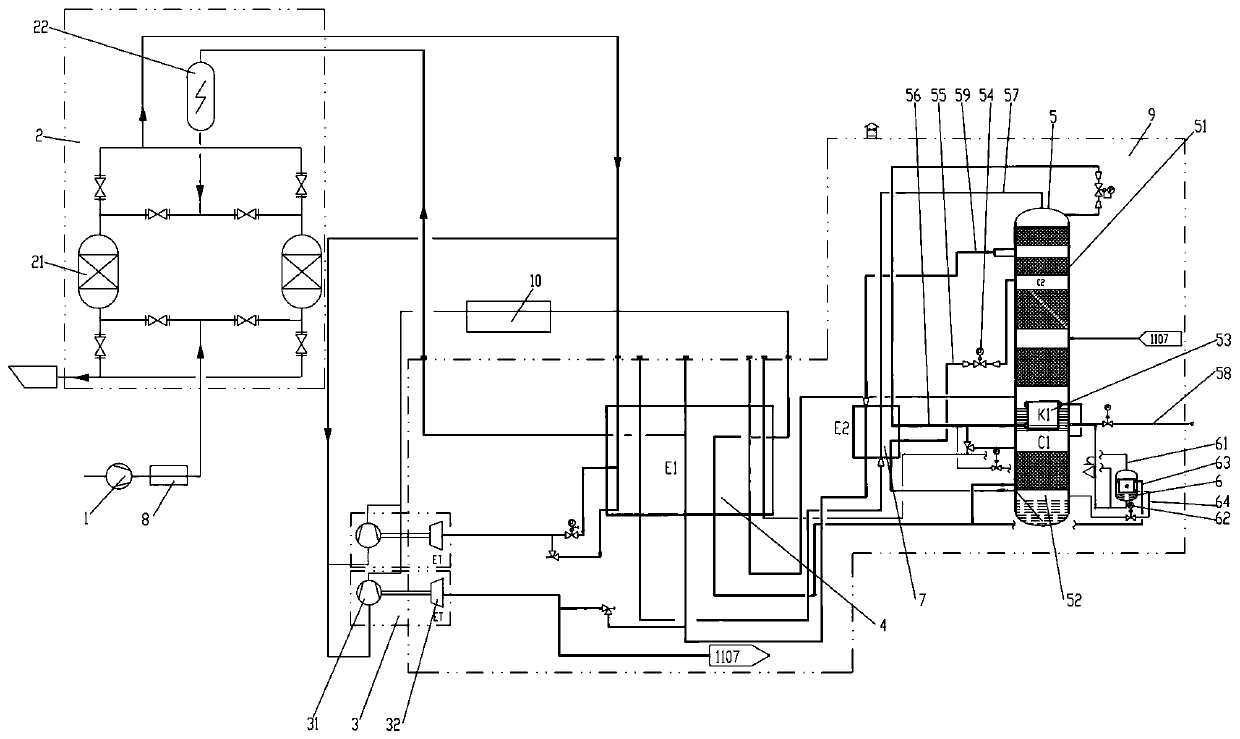

[0020] Such as figure 1 As shown, a nitrogen self-pressurized air separation plant includes an air compressor 1 that compresses external air, a molecular sieve purification device 2 that purifies the air output by the air compressor 1, and a device that expands and refrigerates the purified air. Supercharged turboexpansion device 3, the rectification tower 5 that will separate the air passing through supercharged turboexpansion device 3 into oxygen and nitrogen, and the heat exchanger 4 for the gas in the air separation device to exchange heat; the heat exchange The device 4 and the rectifying column 5 are located in the cold box 9.

[0021] Described air separation unit also comprises that described pre-cooling device 8 that is located between air compressor 1 and molecular sieve purification unit 2 is a water chiller, and it is according to the vari...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap