cCartridge case primer three-dimensional trace feature acquisition device and method

A bullet casing and bullet casing technology, which is applied in the field of criminal investigation and identification, can solve the problems of not being able to accurately reflect the depth of the trace depression and being easily affected by the sunlight environment, and achieve the effect of simple structure, low cost and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

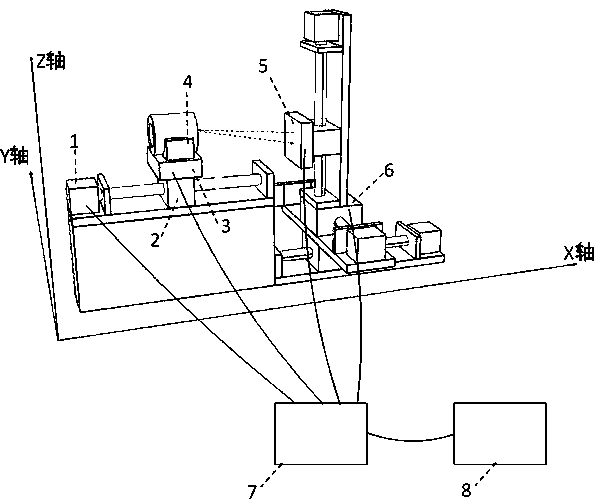

[0055] A three-dimensional trace feature acquisition device of bullet casing primer includes a loading slide table, a loading slide block, a two-dimensional angle platform, a bullet case clamp, a displacement sensor, a multi-dimensional adjustment platform, a control circuit and a computer. The loading slide table, the two-dimensional The angle platform, the displacement sensor, the multi-dimensional adjustment platform and the computer are all connected with the control circuit;

[0056] The loading slide is used for loading and unloading cartridge cases, and adjusting the distance between the cartridge case and the displacement sensor;

[0057] The loading slider is used to carry the two-dimensional angle platform and the cartridge case fixture, and can move along the X-axis along the screw rod under the control of the loading slide;

[0058] The two-dimensional angle platform is used to adjust the bottom plane of the cartridge case so that it rotates around the Y axis or th...

Embodiment 2

[0066] A method for collecting three-dimensional trace features of a bullet casing primer comprises the following steps:

[0067] Step 1, put the cartridge case to be tested into the cartridge case holder;

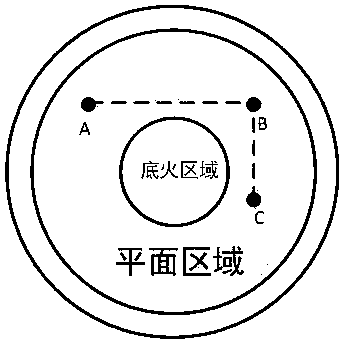

[0068] Step 2: Select at least three reference points for the bottom plane of the shell case in the bottom plane area of the shell case. Among the line segments formed by the three points, at least one line segment is parallel to the Y axis, and the other line segment is perpendicular to it, and the coordinate values of each point are transmitted to the control circuit. ;

[0069] Specifically, in step 2, the operator selects three reference points A, B, and C of the bottom plane of the shell case in the plane area of the bottom plane of the shell case by inputting parameters in the computer, such as figure 2 shown. Among them, the line segment AB is parallel to the Y axis, and the line segment BC is perpendicular to the line segment. The computer transmits the A,...

Embodiment 3

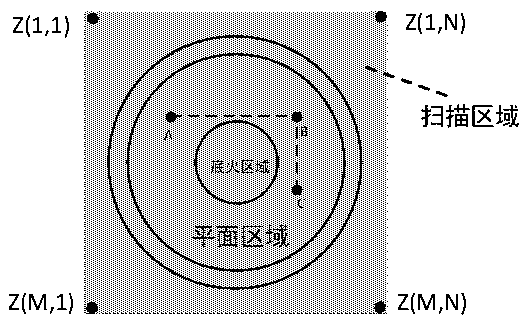

[0093]The load slide table is a Kojin XA10A-L101 automatic single-axis slide table, the load slider is a customized aluminum alloy slider, the two-dimensional angle platform is a Kojin SA04B-RS02 two-dimensional angle platform, and the cartridge case clamp is an adjustable plastic clamp. The displacement sensor is Panasonic HL-G108A-RS-J laser point displacement sensor, the multi-dimensional adjustment platform is Seiko KWC06020-LG high-precision XYZ three-axis slide table, and the control circuit is a circuit control board with STM32F407 as the core. Take the shell traces with a scanning radius of 5[mm] as an example, set the scanning area length L=14[mm], height H=14[mm], scanning accuracy M=100 rows, N=100 columns, scanning K=6 group data.

[0094] First, the operator places the casing to be tested onto the gripper. Due to the damage and deformation of the shell itself or human operation, the bottom plane of the shell may not be perpendicular to the Z axis.

[0095] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com