Wearable device

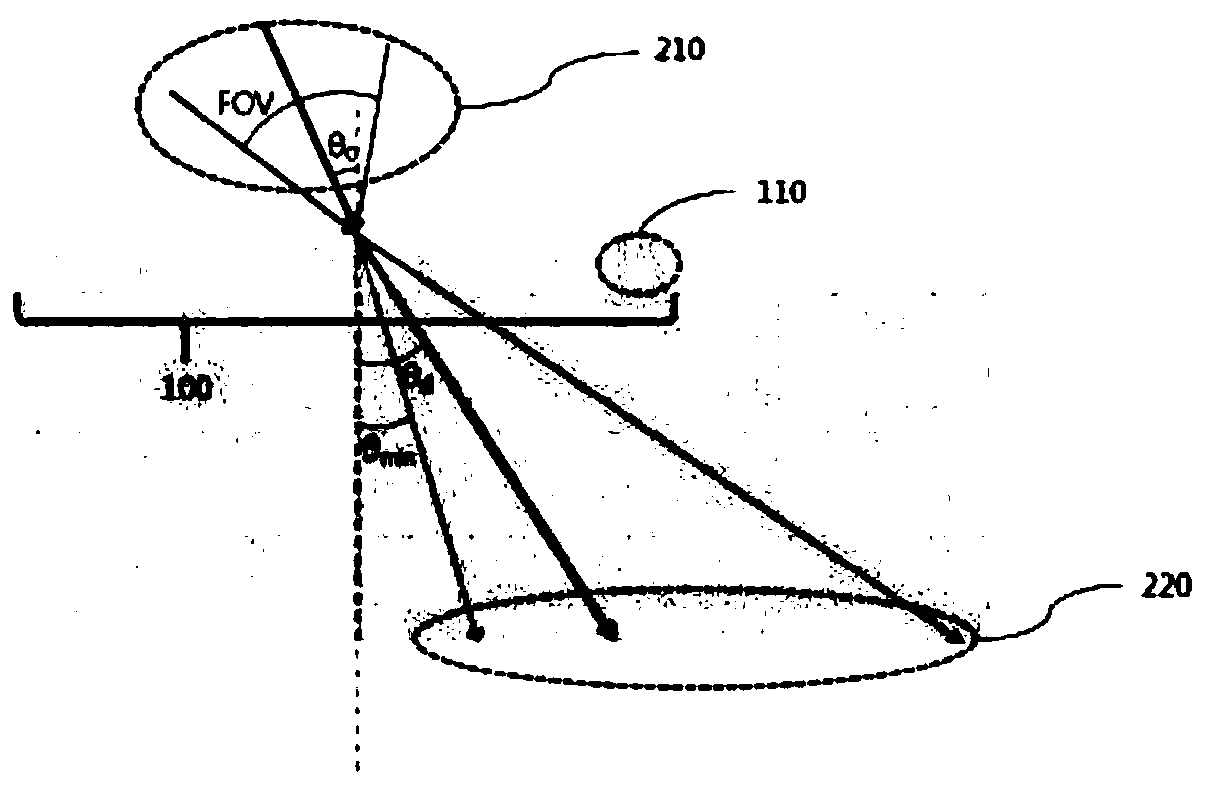

A wearable device and plastic lens technology, which is applied in image data processing, optics, instruments, etc., can solve the problems of eye damage, heavy glass substrate, inconvenient wearing of glass substrate for a long time, etc., achieve excellent resolution and prevent light reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A plastic lens substrate having an optical refractive index of 1.70 at a wavelength of 532 nm and a thickness of 0.5 mm was produced by a mold casting method in which a buffer spacer was applied using MGC Lumiplus LPJ-1102 as a material. The thickness deviation of the produced plastic lens substrate was 0.5%.

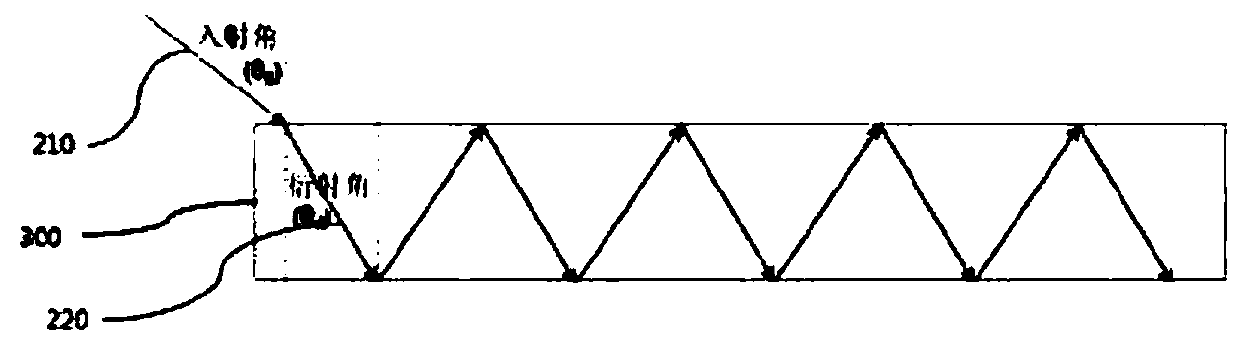

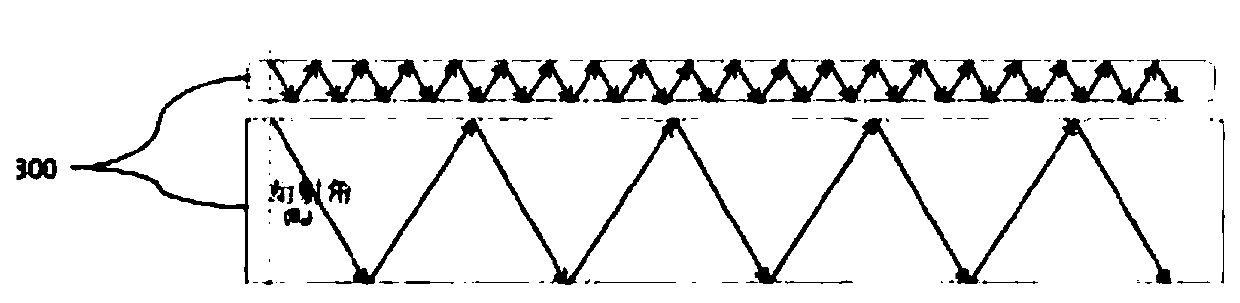

[0105] In addition, the fabricated plastic lens substrate was cut into 50 × 50mm 2 , and then apply a UV-curable imprint resin at a thickness of 1 μm on one surface. A film-type mold was pressed, in which a diffractive light guide pattern with a pitch of 425 nm, a depth of 125 nm, and a duty ratio of 0.4 was formed on the mold in the form of an engraved film, and then exposed to UV to produce a diffractive light guide pattern on a plastic lens substrate. Diffractive light guide unit for light pattern.

[0106] The plastic lens substrates according to Examples 2 to 4 and Comparative Examples 1 to 3 and the diffractive light guide units on the plastic lens substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle of view | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com