Movable type rubber tapping robot

A robotic and mobile technology, applied in the field of robotics, can solve problems such as difficulty in precise positioning and poor rubber forest signal, and achieve the effects of high cutting accuracy, reduced tool shaking, and enhanced robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

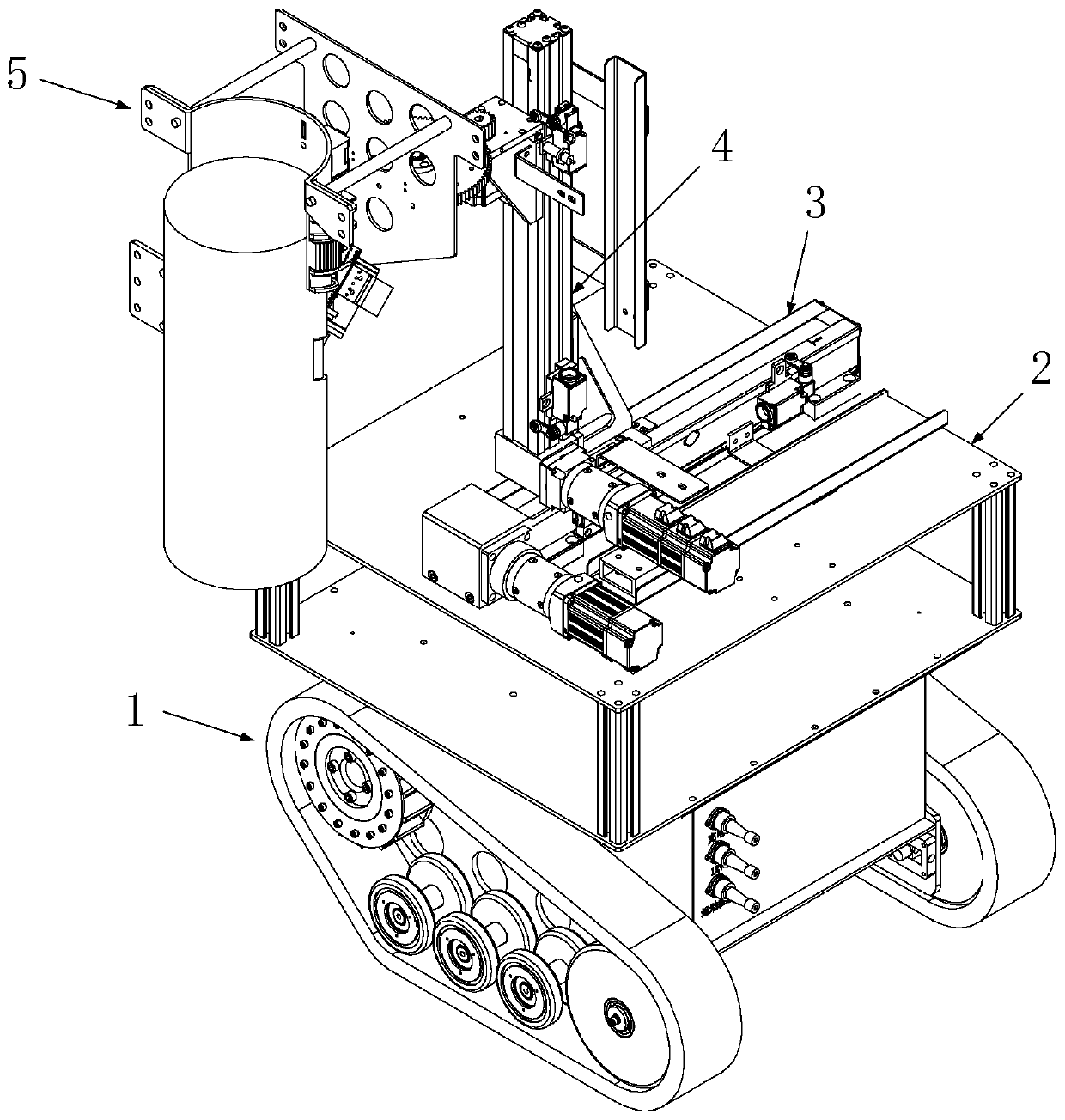

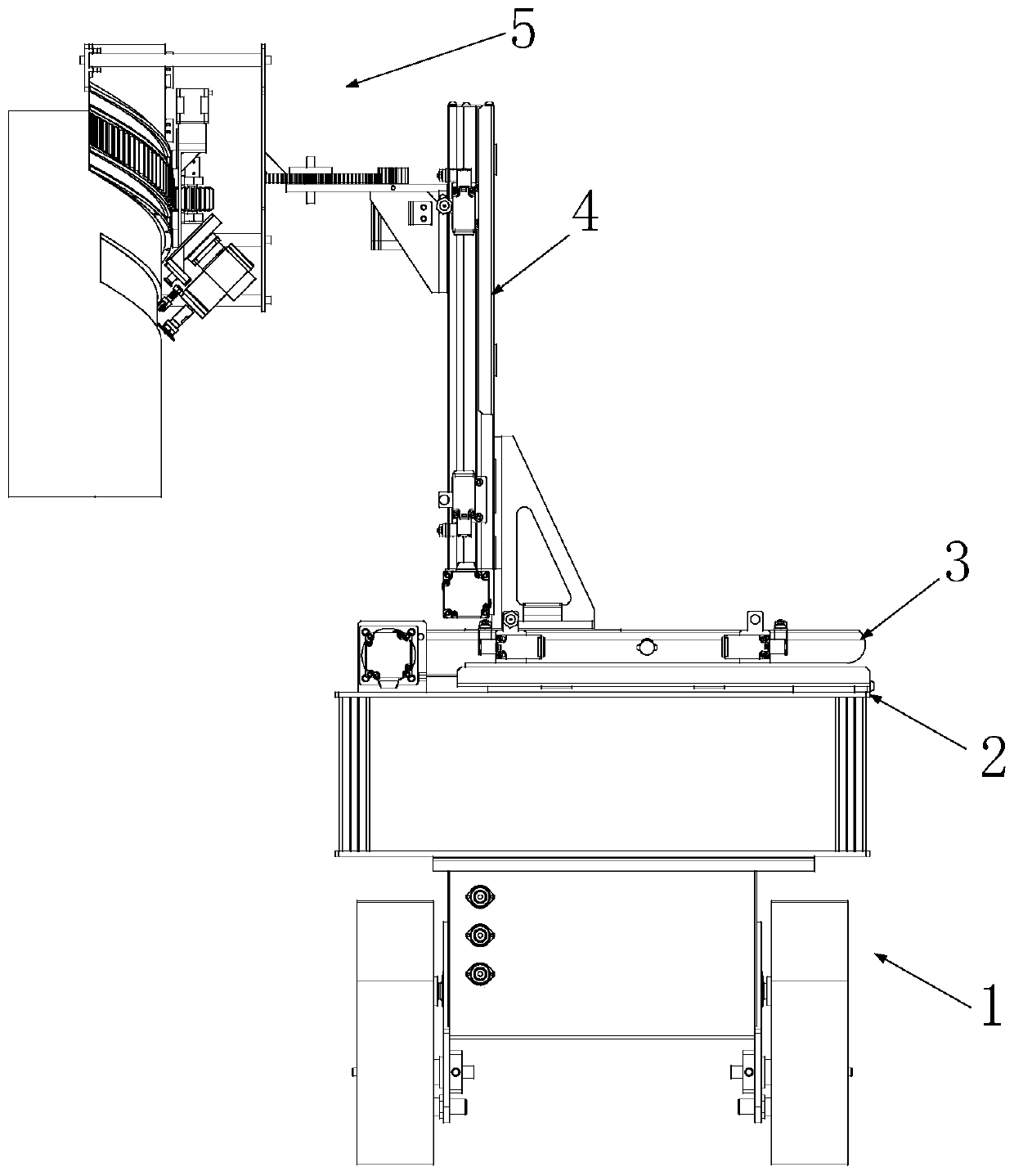

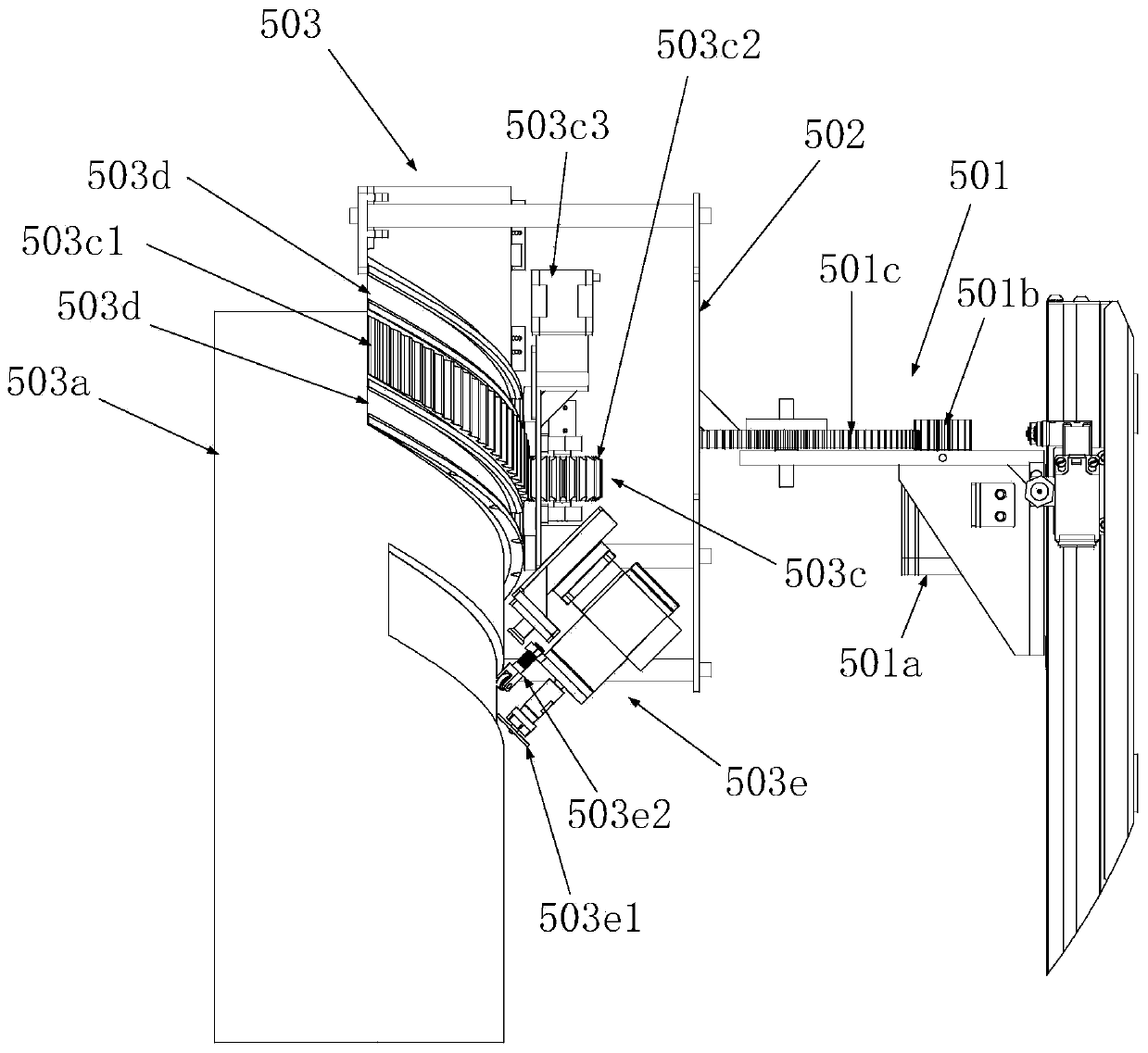

[0027] The mobile rubber tapping robot of the present invention includes a mobile platform 1, a support table 2, a horizontal guide rail slider group 3, a vertical guide rail slider group 4, and a mobile rubber tapping robot end 5, such as figure 1 , figure 2 , image 3 Shown.

[0028] The mobile platform 1 adopts a crawler-type mobile platform to realize the movement of the robot in the rubber tapping process, and adopts the method of a crawler-type mobile platform to enable the robot to run on uneven roads. A support platform 2 is installed on the mobile platform 1, and the support platform 2 has a rectangular structure and is arranged horizontally. The four circumferential corners are installed on the support columns at the four corners of the rectangular platform in the mobile platform 1.

[0029] The horizontal rail and slider group 3 is installed on the support platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com