Compound fertilizer raw material reaction barrel

A compound fertilizer and reaction barrel technology, applied in chemical/physical/physical chemical fixed reactors, detailed information of chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve urea and formaldehyde Slow response, easy to cause vortex, drop and other problems, to achieve the effect of isolating noise, improving sealing and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

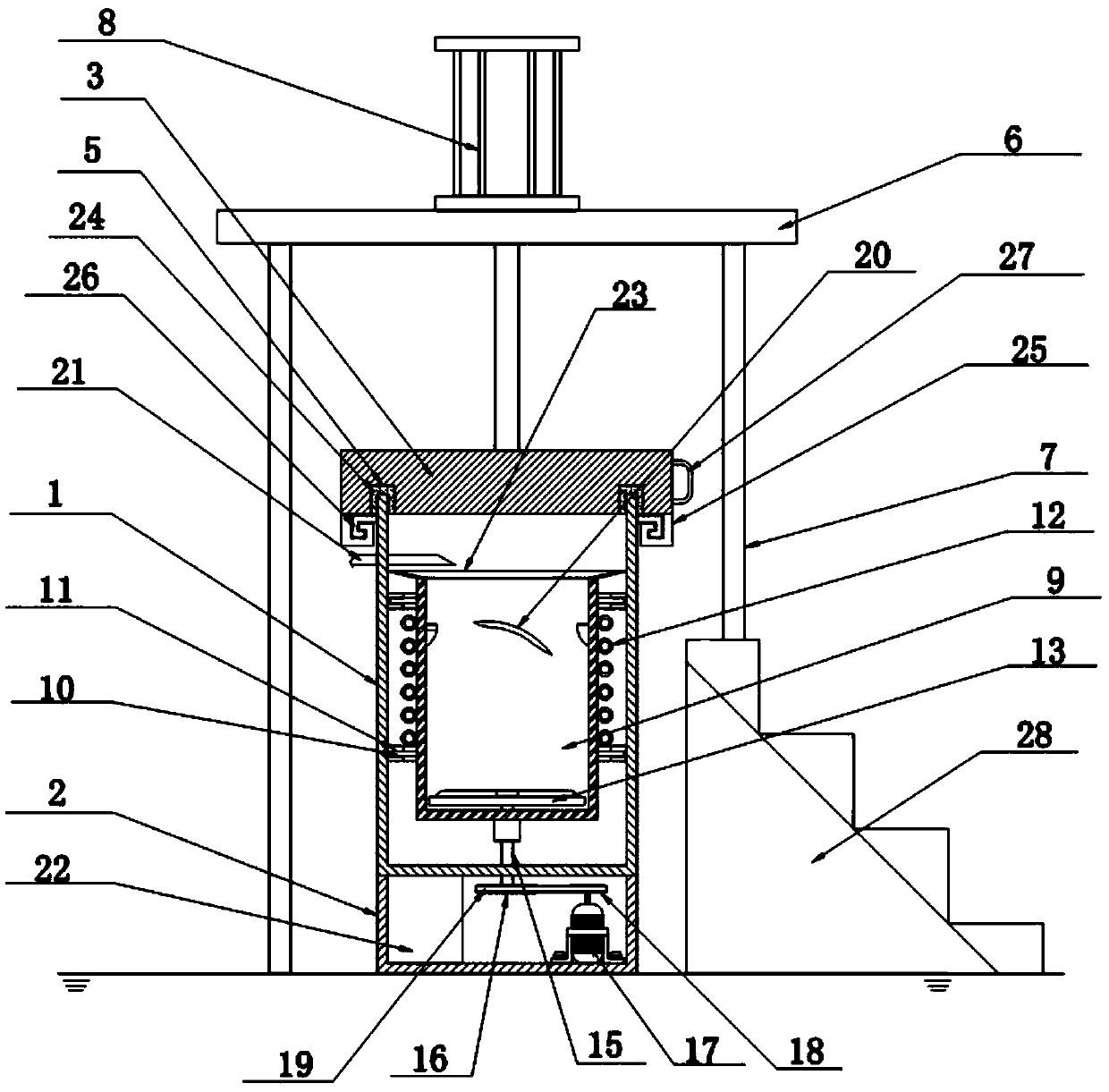

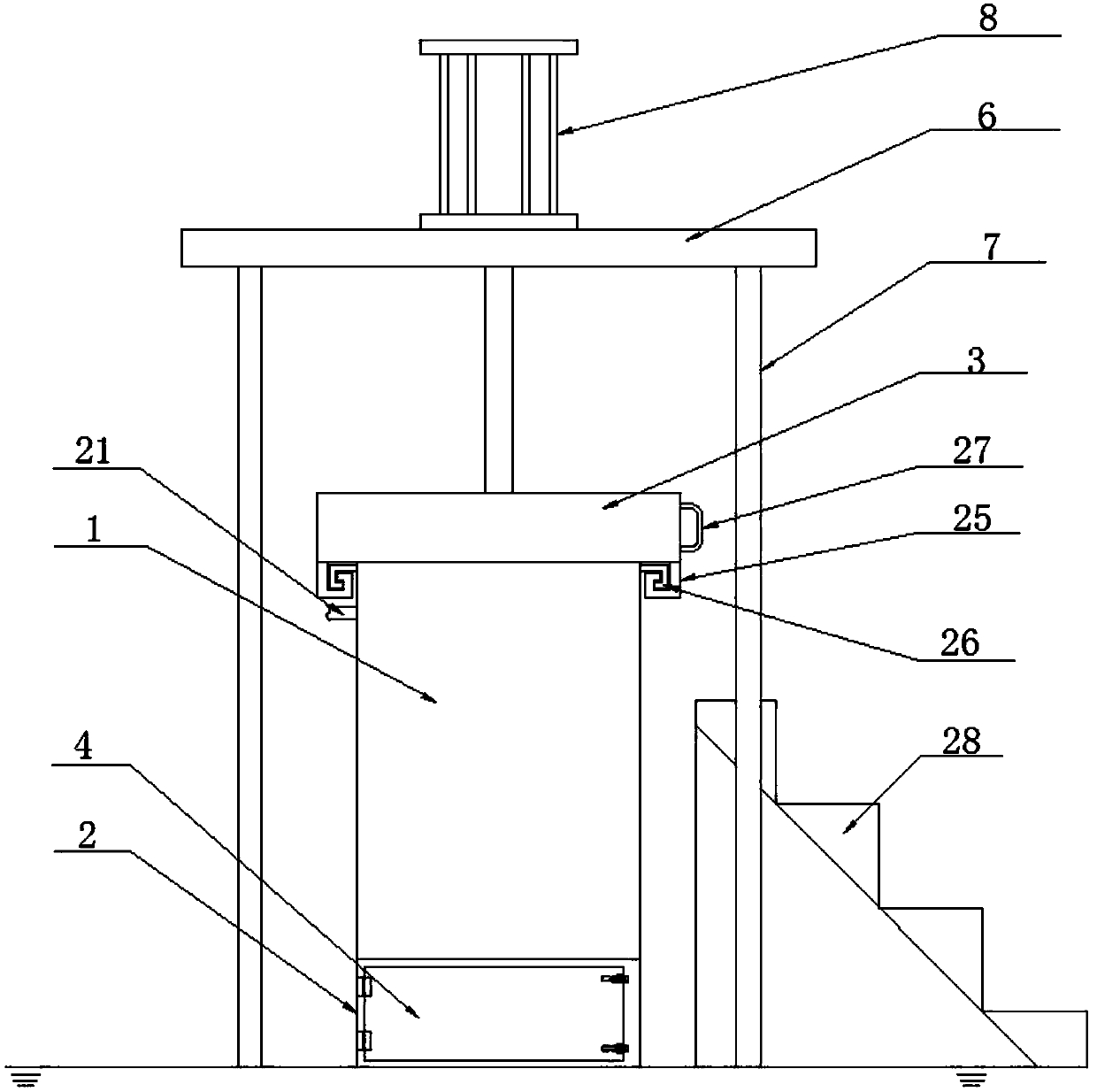

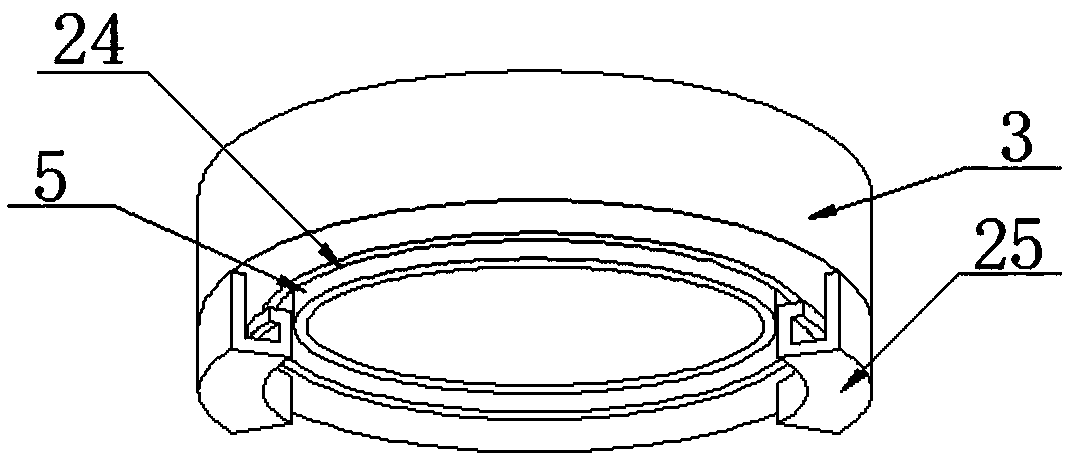

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as Figure 1-Figure 5 Shown, the technical scheme that this specific embodiment adopts is: it comprises No. 1 box body 1 (diameter is the box body of 1800mm cylindrical band anticorrosion coating), No. 2 box body 2 (diameter is the box body of 1800mm cylindrical band anticorrosion). coated box), box cover 3 (diameter is greater than the diameter of No. 1 box 1), box door 4; the bottom of No. 1 box 1 is fixedly welded with No. 2 box 2 (shelving box for electrical components) , No. 1 box body 1 is a hollow structure with an upper opening, No. 2 box body 2 is a hollow structure with an open front side wall, and the front side wall of No. 2 box body 2 is provided with a box door 4 through hinge rotation, and the box door 4 The right side of the No. 2 box body 2 is fixedly connected to the front side wall of the No. 2 box body 2 through several hasps, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com