An automatic painting system for motor production

A technology for automatic painting and motor casings, applied in painting booths, spraying devices, coatings, etc., can solve problems such as paint mist escaping, damage to workers' health, and paint mist polluting the environment to achieve improved efficiency, high processing efficiency, and The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

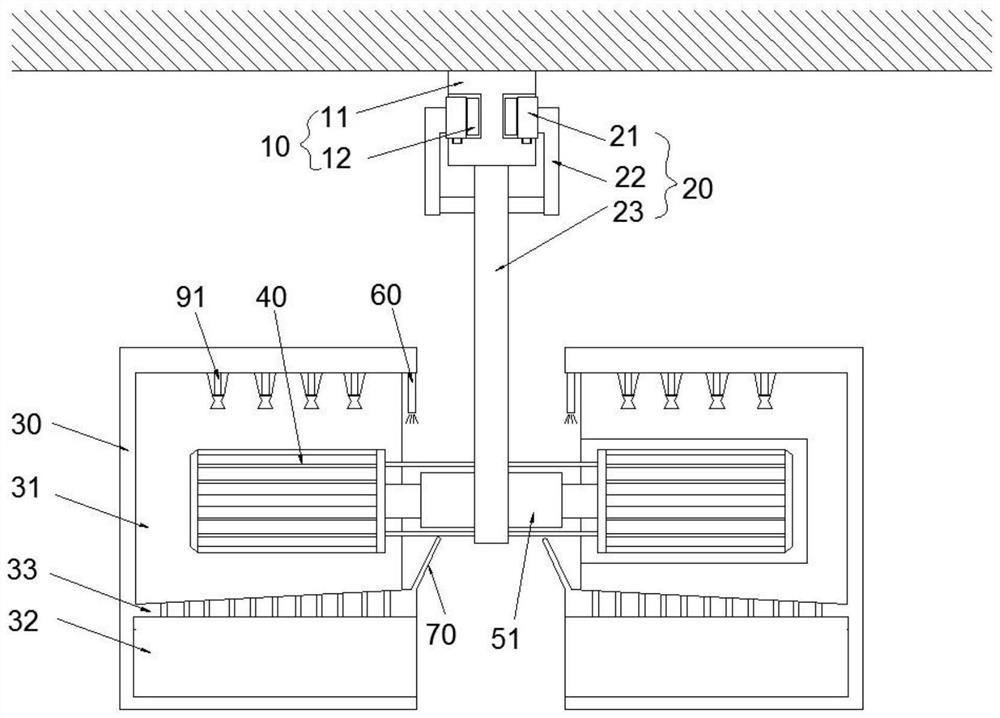

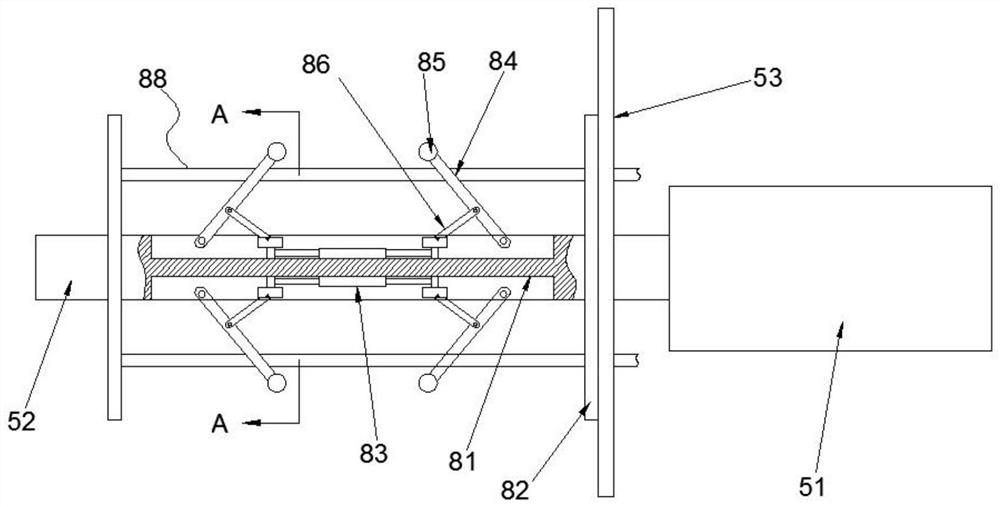

[0030] see Figure 1-4 , an automatic painting system for motor production, comprising a sliding mechanism 10, a mobile frame 20 slidably connected to the sliding mechanism 10, a support mechanism for fixing the motor casing 40, and a working room 30, and the bottom end of the mobile frame 20 is installed The driving mechanism that drives the supporting mechanism to rotate, and the supporting mechanism extends into the inside of the motor casing 40 to fix the motor casing 40 .

[0031] The working chamber 30 is provided with a processing chamber 31 , wherein the moving frame 20 slides along the sliding mechanism 10 , so that the motor casing 40 on the supporting mechanism at the bottom of the moving frame 20 moves in the working chamber 30 .

[0032] In the chamber 30, from one side to the other, there are paint spraying area, transition area, drying area and cooling area.

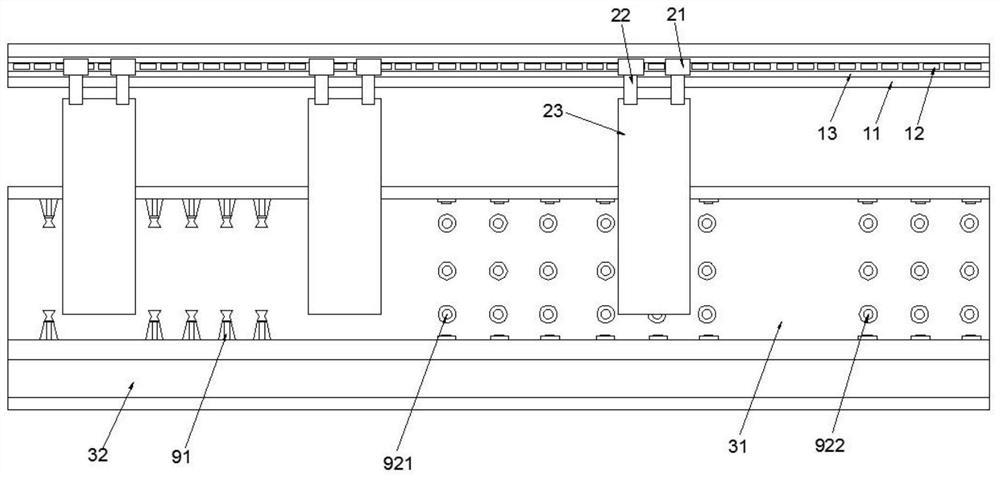

[0033] Step, the sliding mechanism 10 includes a slide rail 11, a transmission chain 12 and a chute 13...

Embodiment 2

[0042] see figure 1 , figure 2 , in this embodiment, on the basis of Embodiment 1, a recycling chamber 32 is also provided below the processing chamber 31 in the working chamber 30, and the recycling chamber 32 is separated from the processing chamber 31 by a partition 33, and the partition The top surface of 33 is a slope, and the outer end of partition 33 is fixed with guard plate 70 inclined upwards, and several through holes are evenly opened on partition 33, and the through holes communicate with processing chamber 31 and recovery chamber 32.

[0043]Further, the side of the working chamber 30 near the mobile frame 20 is open, and the top of the inner wall of the working chamber 30 is installed along the length direction of the working chamber 30 near the opening. The nozzles 60 spray water downwards to form The water curtain is convenient to isolate the paint mist generated by spraying the paint. The water curtain produced by the nozzle 60 can isolate or absorb the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com