Lithium battery pelleter

A technology of tablet machine and lithium battery, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as reduced effect and battery damage, and achieve the effect of avoiding damage and flying around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

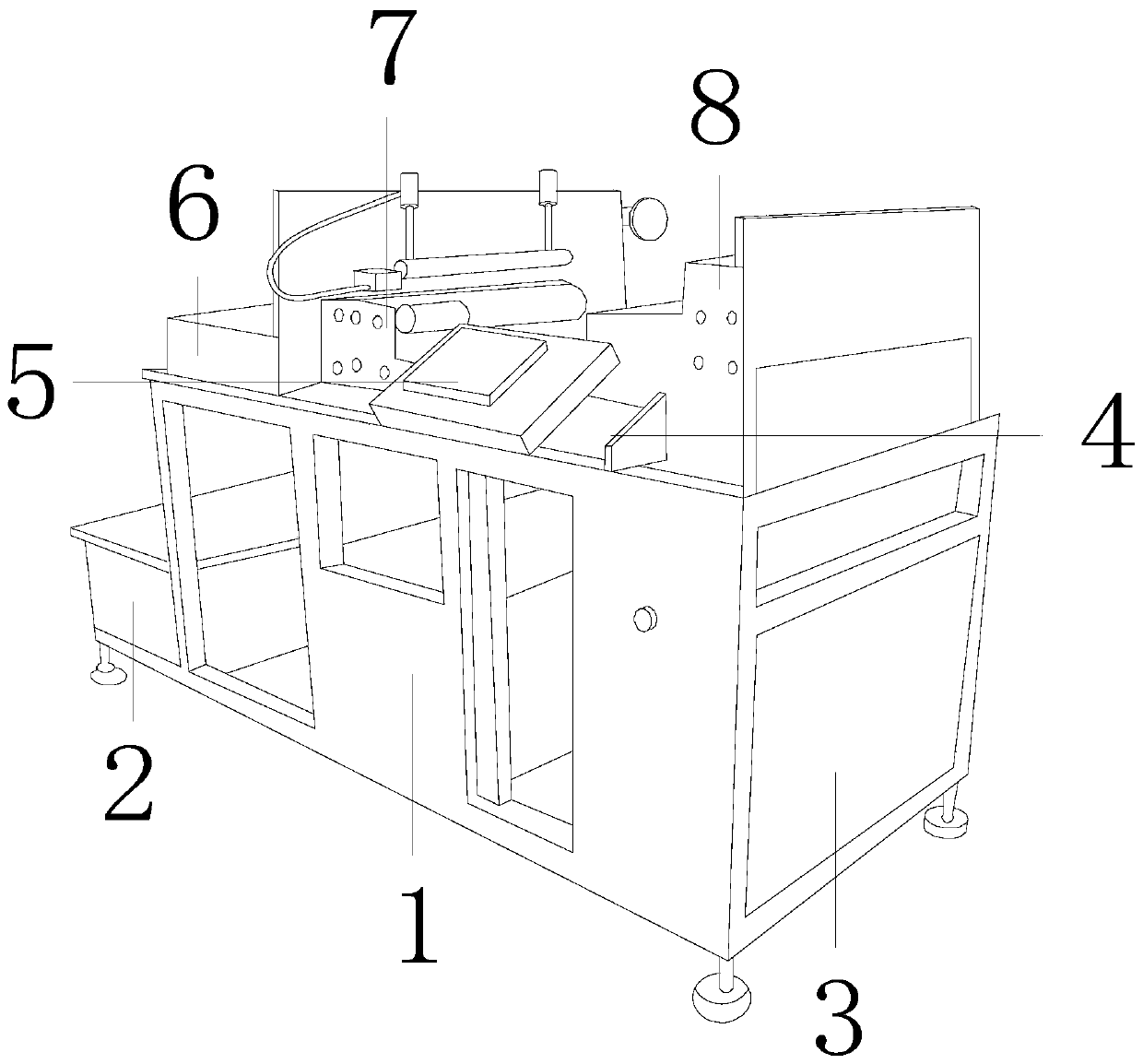

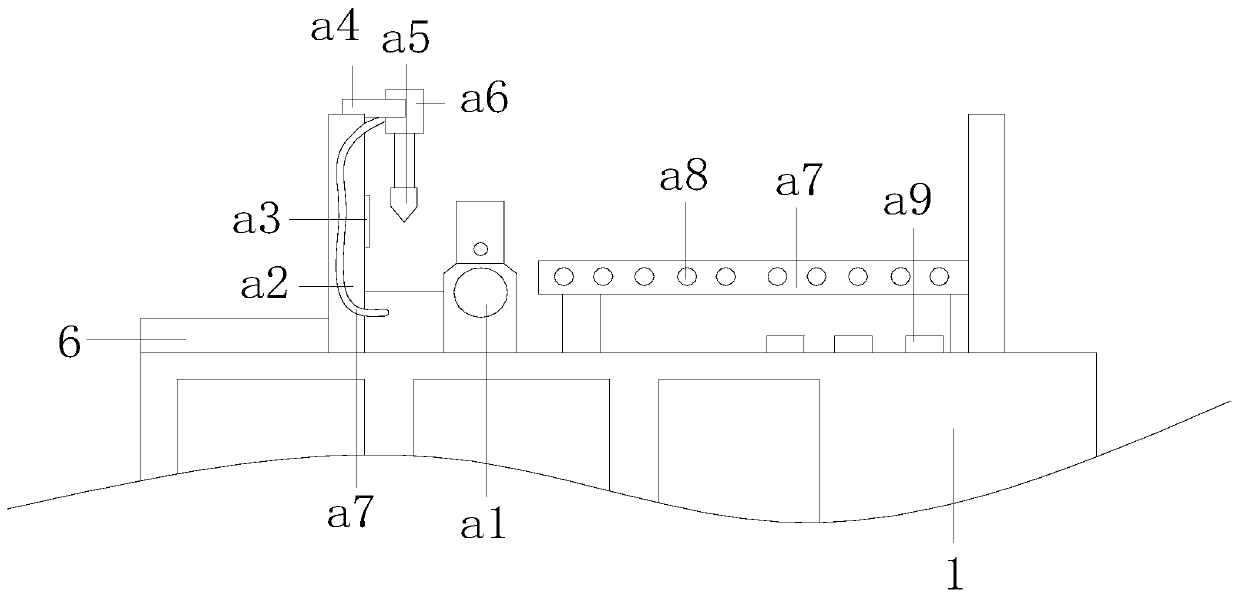

[0026] Such as Figure 1-Figure 5 Shown:

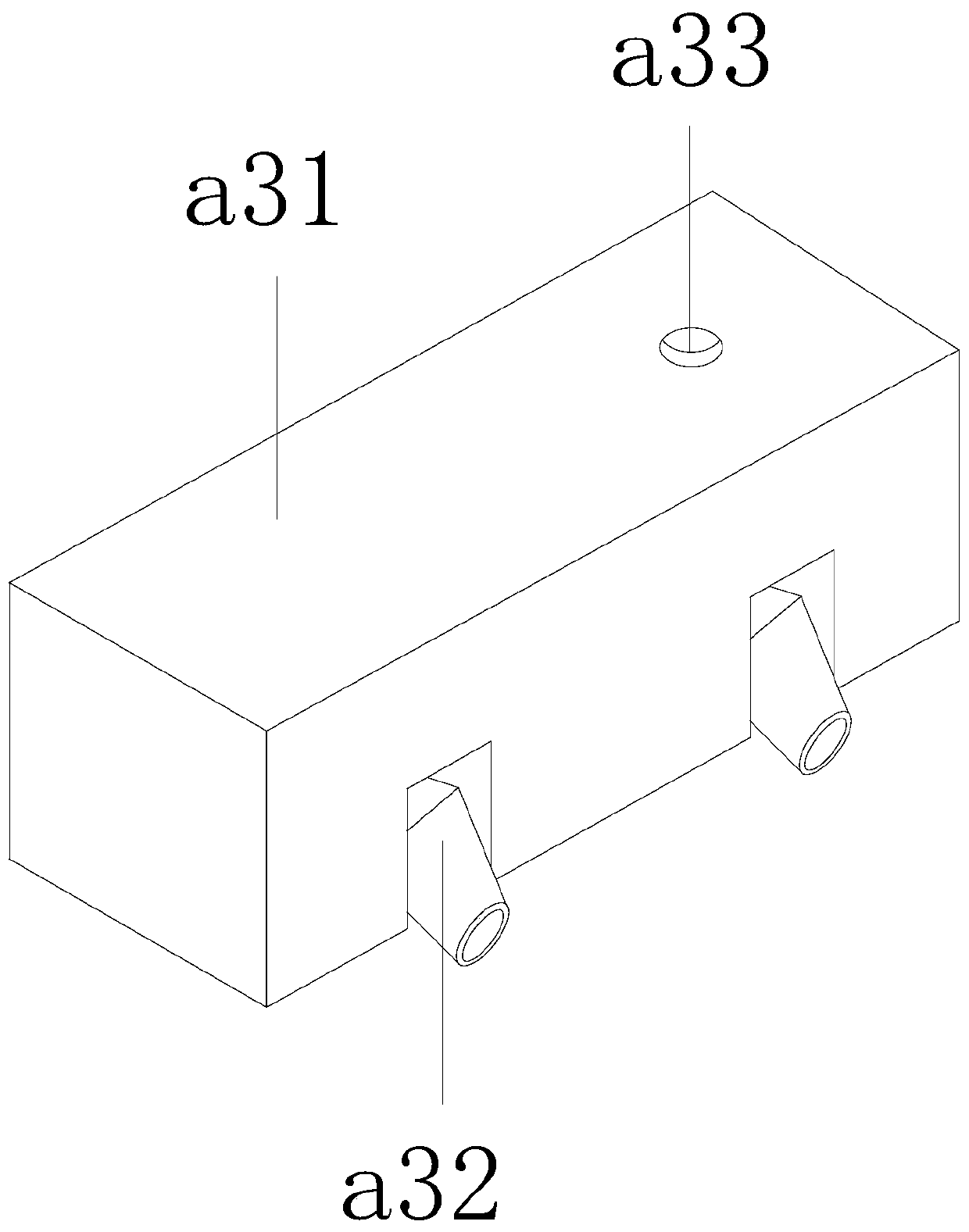

[0027] The present invention provides a lithium battery tablet machine, the structure of which includes a cabinet body 1, a tool box 2, a motor box 3, a placing table 4, a control board 5, a fixing plate 6, a cutting mechanism 7, and a transfer table 8. The tool box 2 The clearance fit is at the lower left position of the cabinet 1, the motor box 3 is embedded and connected to the right side of the cabinet 1, the transfer table 8 is bolted to the right side of the top of the cabinet 1, and the placement table 4 is welded to On the side of the conveying table 8, the control board 5 is fixed above the placing table 4, the fixing board 6 is attached to the left side of the cutting mechanism 7, and the cutting mechanism 7 is embedded and connected to the middle of the cabinet 1. The cutting The mechanism 7 mainly includes a dust removal device a1, a combined plate a2, a blowing mechanism a3, a support rod a4, a rod sleeve a5, a knife rod a6,...

Embodiment 2

[0034] Such as Figure 6-Figure 8 Shown:

[0035] The present invention provides a lithium battery tablet machine. The dust removal device a1 mainly includes a main pipe c1, a hollow protective plate c2, a pipe cover c3, a handle c4, a dust collecting tube c5, and a fixing block c6. The hollow protective plate c2 is welded Connected to the left and right sides of the main pipe c1, the pipe cover c3 is installed on the side of the main pipe c1 with a clearance fit, the dust collecting pipe c5 is embedded and connected inside the main pipe c1, and the fixing block cc6 is riveted and connected to the main pipe At the angle between c1 and the hollow shield c2, the handle c4 is welded and connected to the front end of the pipe cover c3. There are also several holes around the main pipe c1, which are connected to the dust collection pipe c5 to make it easier for dust to enter Dust collection tube c5.

[0036] Wherein, the dust collecting pipe c5 mainly includes an auxiliary pipe c51, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com