Full-automatic rivet feeding mechanism

A fully automatic, rivet technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of strong manual dependence, inaccurate feeding, and difficult to control the discharge speed, so as to reduce the degree of dependence, the overall structure is simple, and the output The effect of uniform material speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

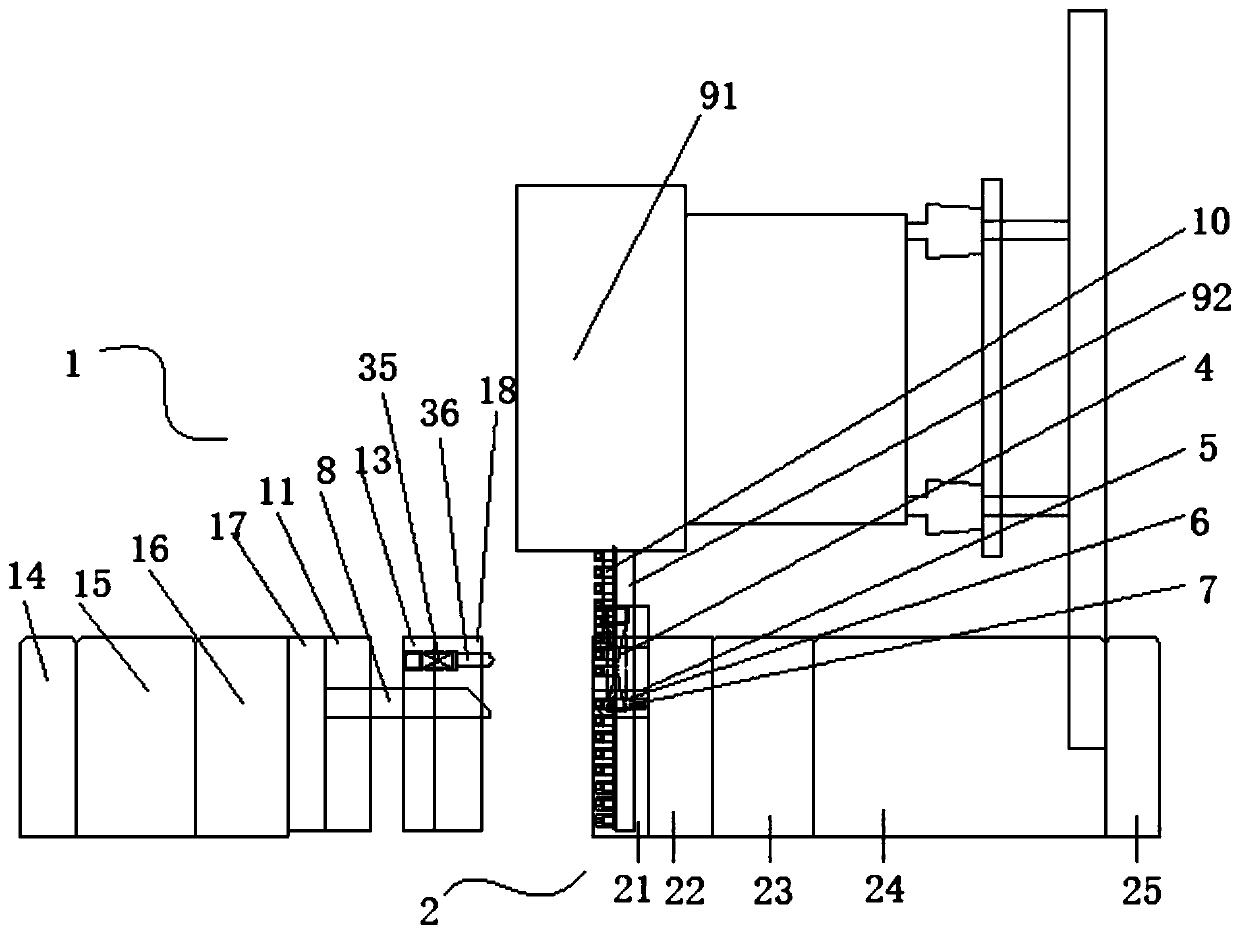

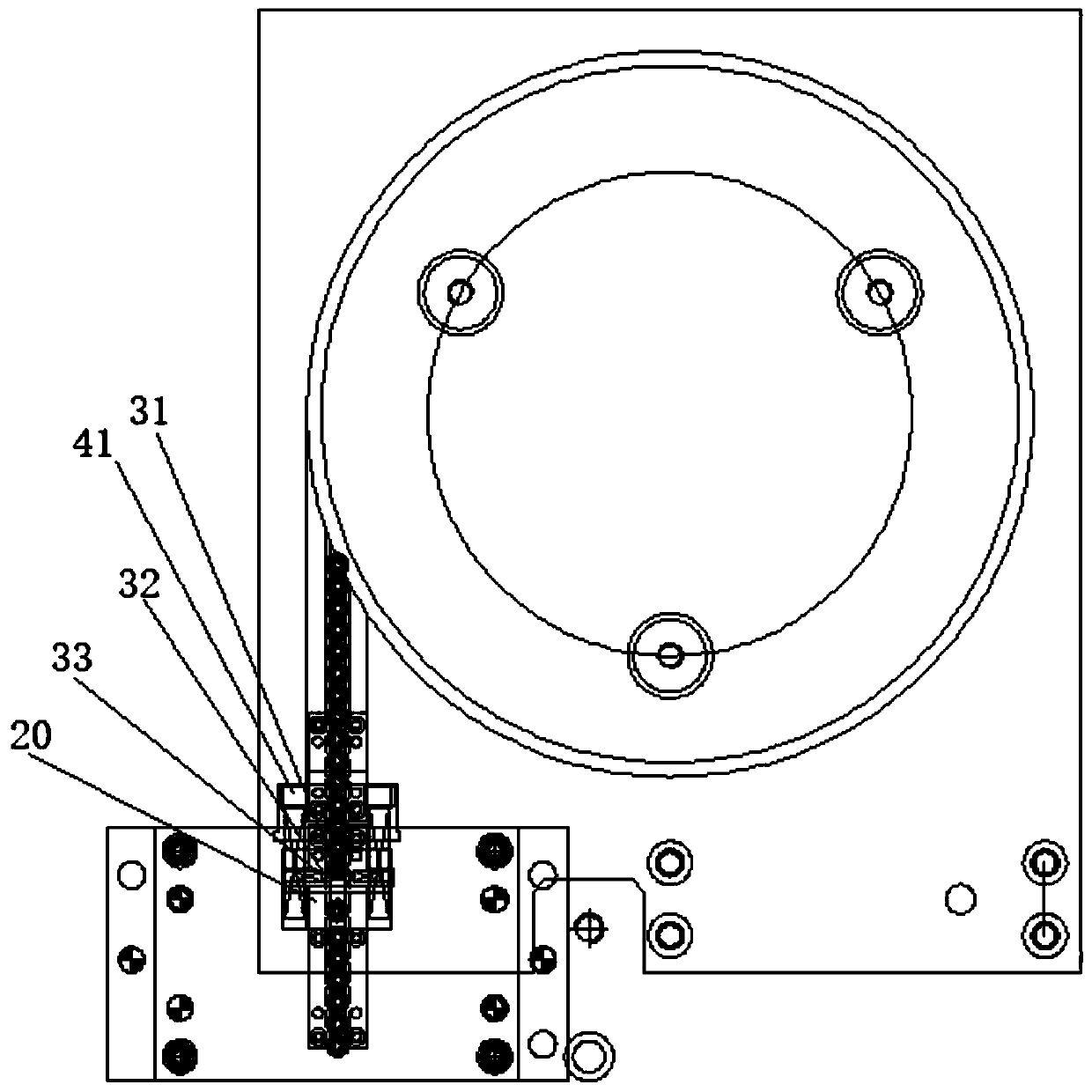

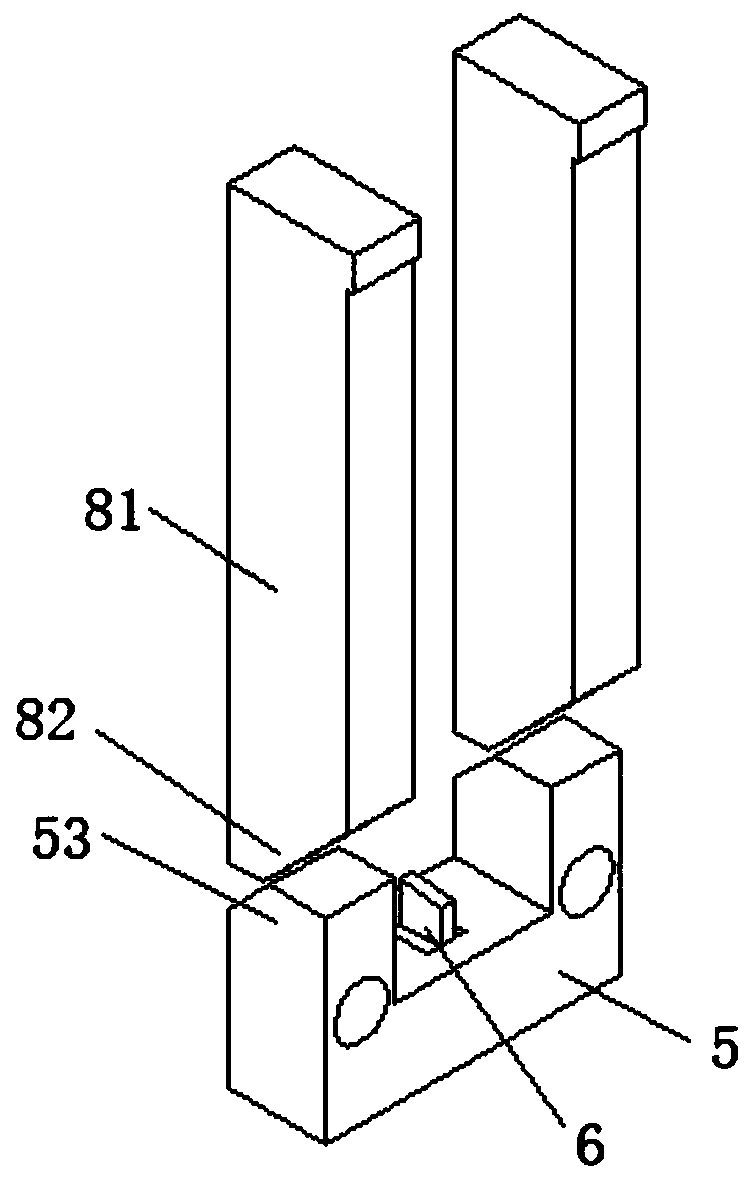

[0023] as attached Figure 1-5 As shown, the present invention provides a fully automatic rivet feeding mechanism, including a mold base device, a vibration plate, a positioning device, a material hanging device and a transfer track, and the positioning device is located between the vibration plate and the material hanging device , the input end of the transfer track is connected to the discharge port of the vibration plate, the output port of the transfer track is connected to the track 20 of the next processing station, and the positioning device and the material hanging device are installed on the mold base superior. The vibrating plate includes a plate body 91 and a vibrating plate track 92 connected with the plate body, and the outlet of the vibrating plate track is connected with the material inlet of the transfer track. The positioning device is mainly used to locate the rivets 10 transferred by the vibrating plate, and the material hanging device is used to feed the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com