Coal machine part repairing and strengthening method

A component and coal machine technology, applied in the field of repair and strengthening of coal machine parts, can solve problems such as use quality and safety issues, high performance requirements, wear and tear of equipment parts, etc., to reduce labor costs and ensure repair efficiency , The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

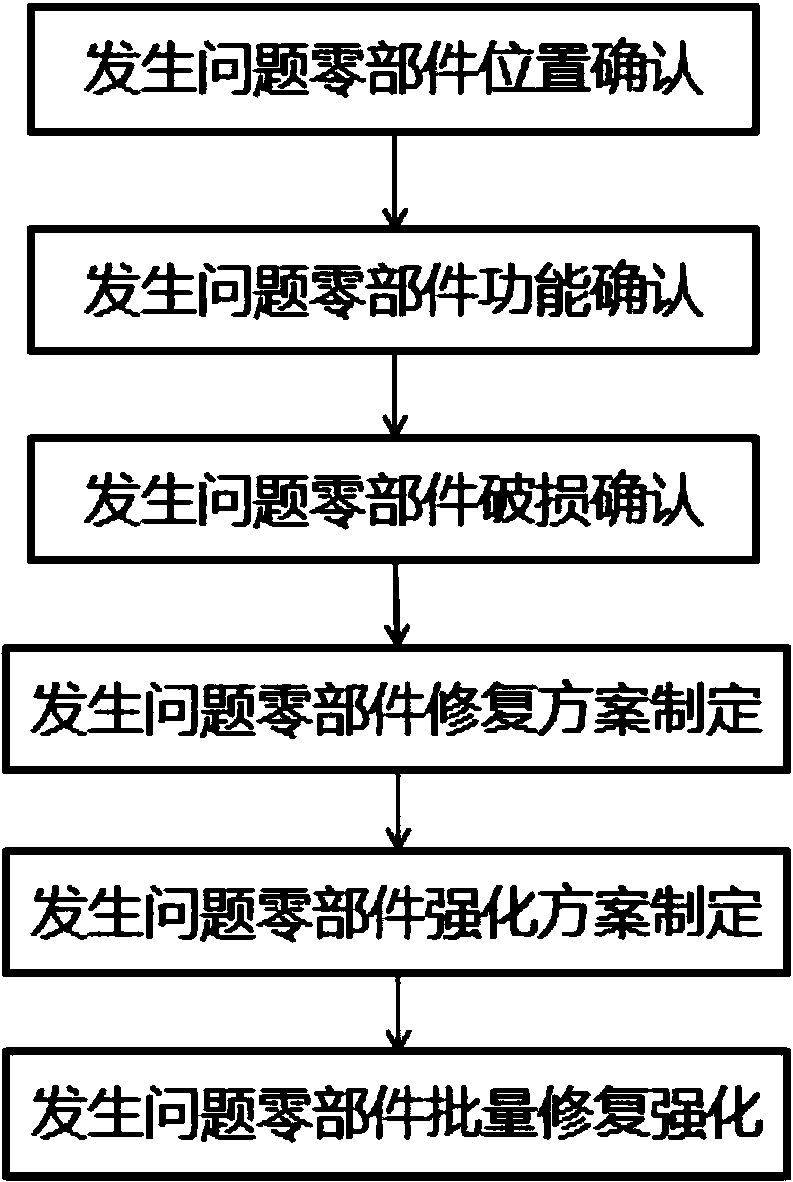

[0030] A method for repairing and strengthening coal machine parts, characterized in that it includes:

[0031] The problem diagnosis step is specifically to analyze the position and function of the damaged coal machine parts, evaluate the damage degree, and formulate a repair and strengthening plan according to the function and damage degree;

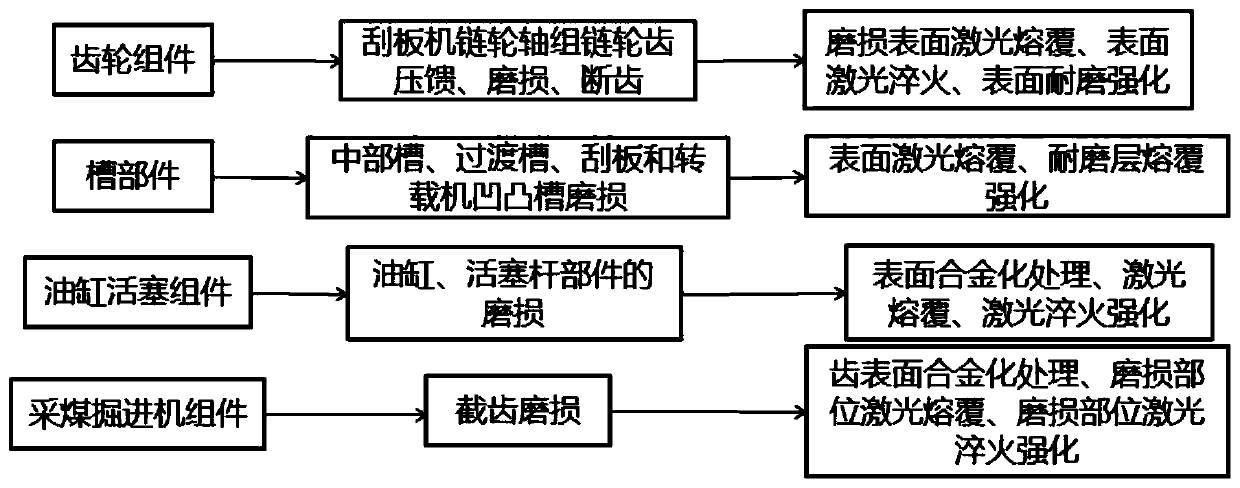

[0032] Specifically, in the coal mine production process, a series of coal machine components are required, involving various components.

[0033] For example, the scraper machine is a transportation machine used in the coal mining face. It is mainly used for transporting along the trough in coal mining face and mining area, and can also be used in coal roadway and semi-coal roadway excavation face. It can be transported upwards or downwards, and the upward transport generally does not exceed 35 degrees. The downward transportation generally does not exceed 25 degrees, and it is advisable not to exceed 20 degrees in practice. It mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com