Modular joint of collaborative robot

A technology of modular joints and robots, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve problems such as brakes, servo drive boards, and uncompact structures, and achieve accurate position feedback, rapid response improvement, and novel structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

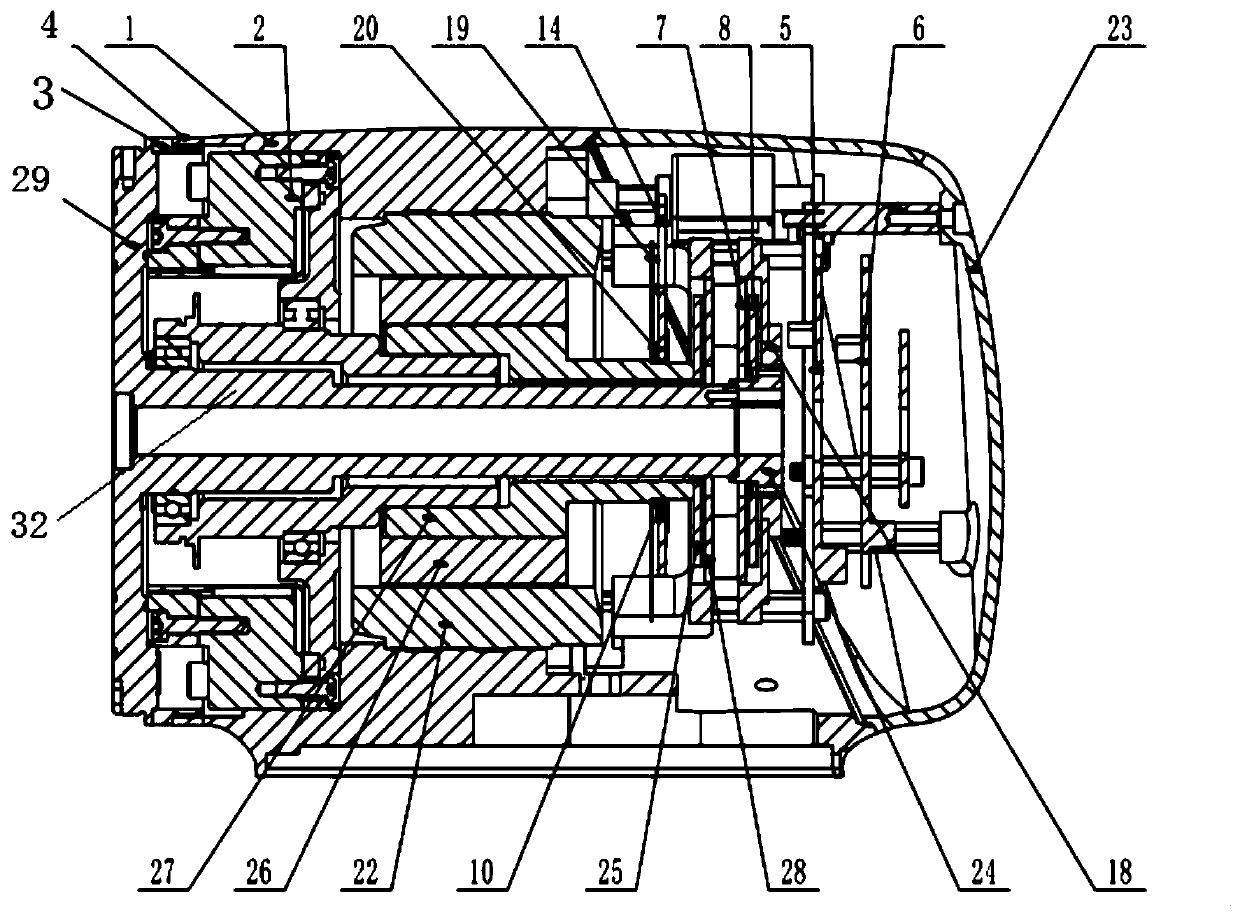

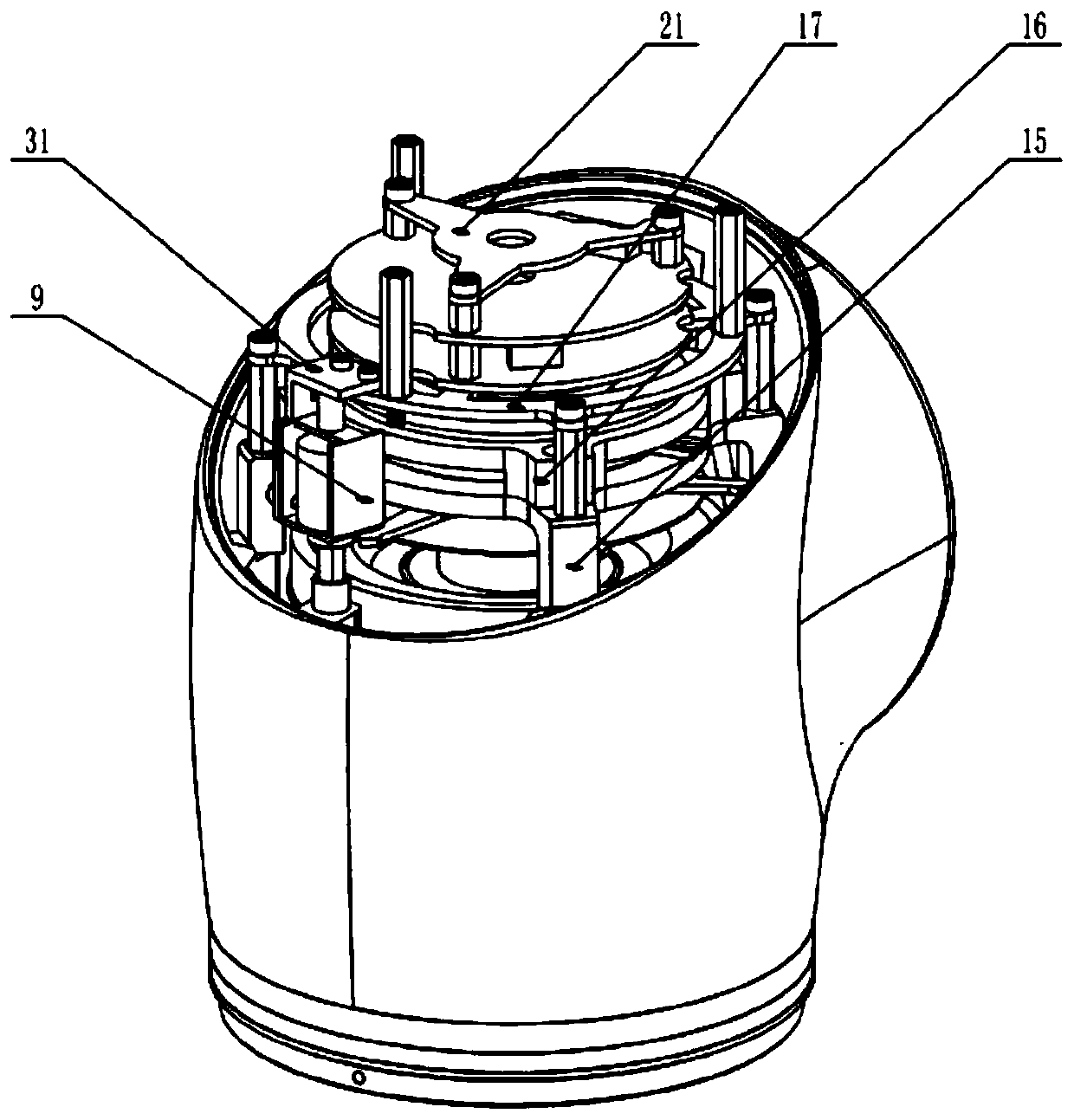

[0038] like figure 1 As shown, a modular joint of a collaborative robot includes a joint shell 1, a motor, a harmonic reducer, and a brake structure. The motor used to drive the harmonic reducer to rotate is installed inside the joint shell 1, and the harmonic reducer serves as The front cover of the joint housing 1 is installed at the end of the joint housing 1 and the output end of the harmonic reducer is set inside the joint housing 1 and connected with the encoder assembly. The plastic ring 3 and the rubber ring 4 are placed on the harmonic reducer Between the joint housing 1.

[0039] The output end of the motor is equipped with brake pads 14, and the brake pads 14 are hexagonal, such as Figure 5 Shown; The brake structure for controlling the brake pad 14 in the braking or non-braking state is installed on the encoder assembly.

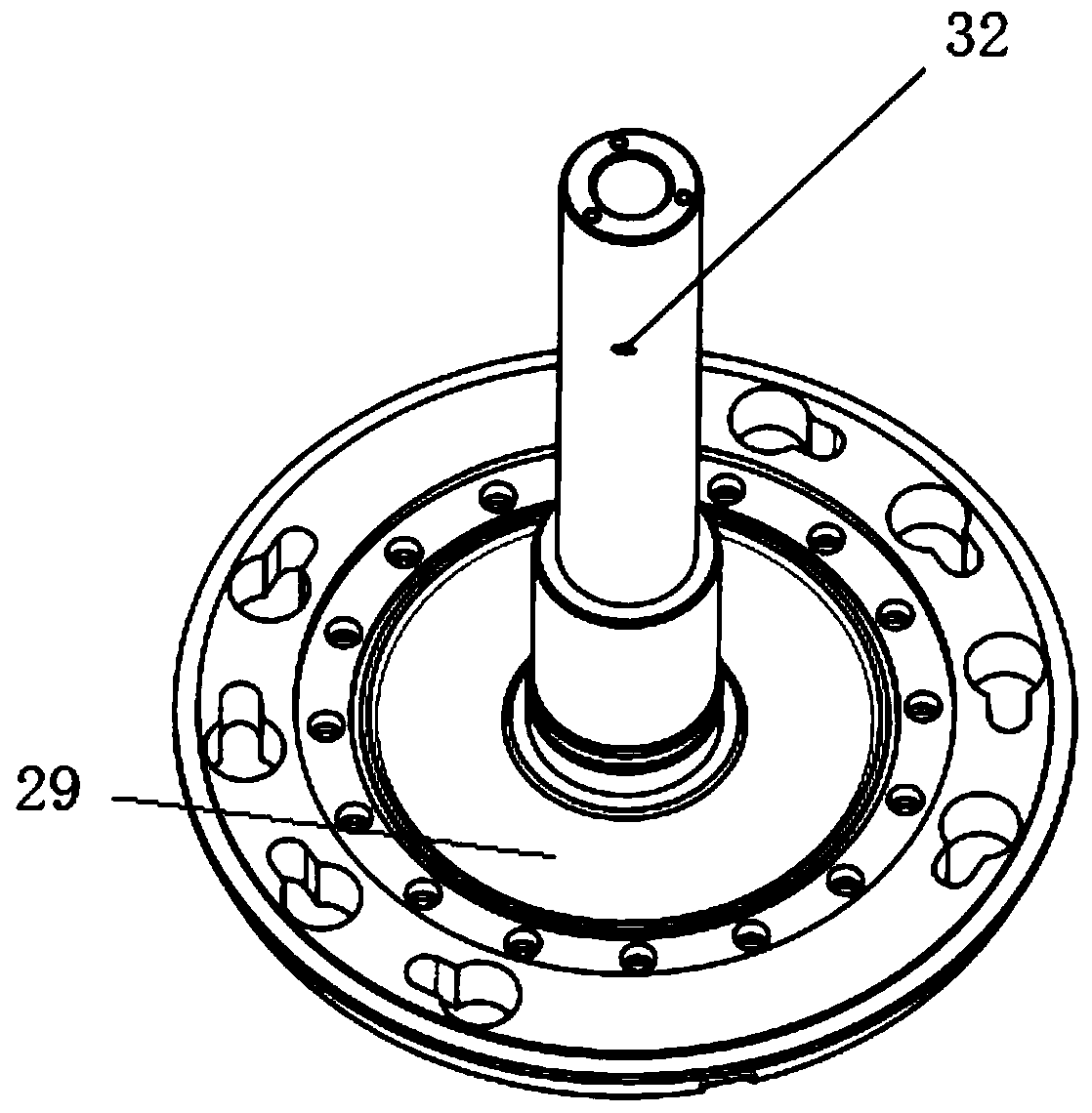

[0040] In this embodiment, the harmonic reducer includes a harmonic reducer body 2 and a harmonic reducer end cover 29 connected to the harmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com