Saw dust collecting device for wood cutting

A collection device and sawdust technology, which can be used in wood processing equipment, forming/shaping machines, manufacturing tools, etc., can solve the troublesome problems of sawdust processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

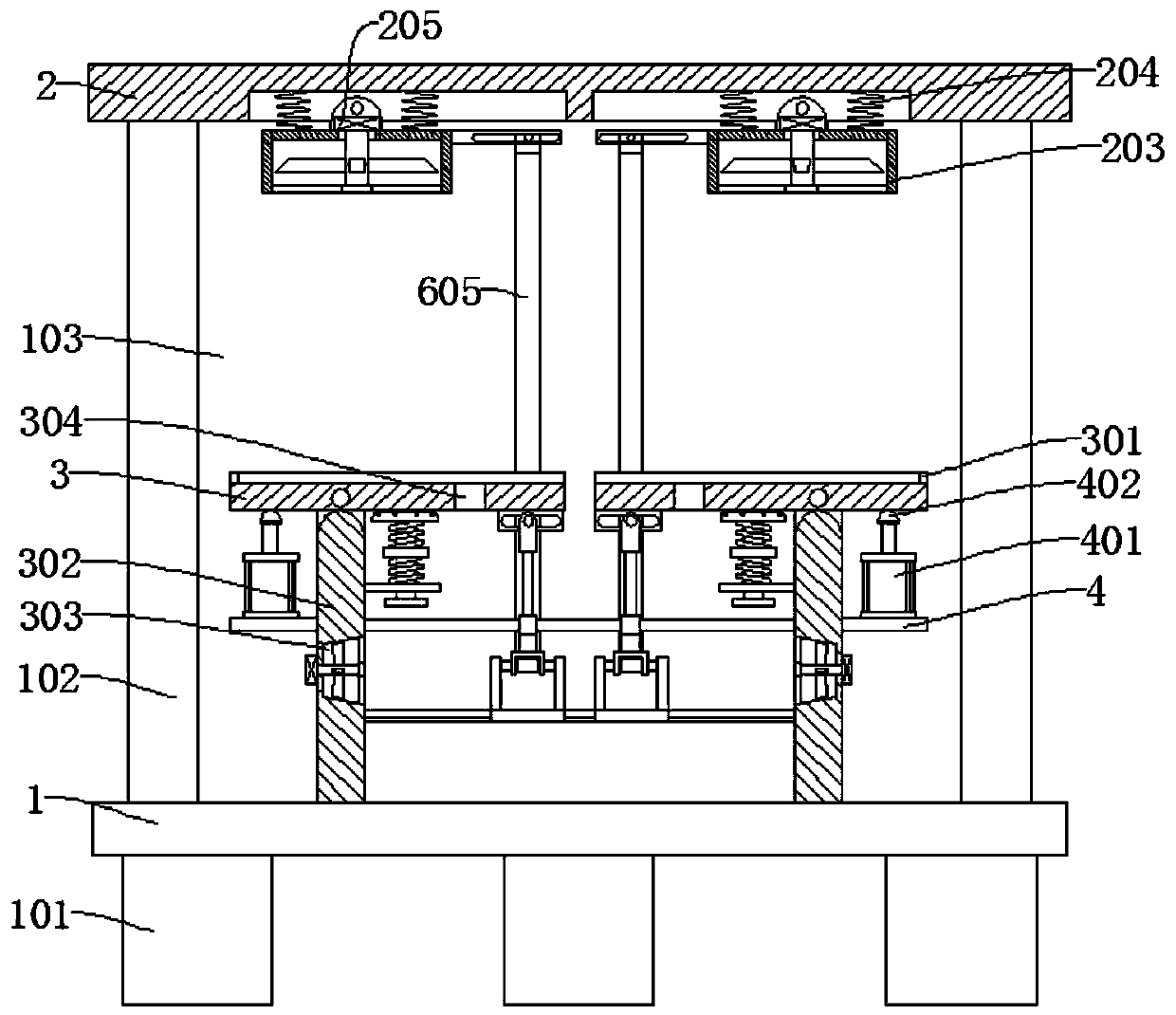

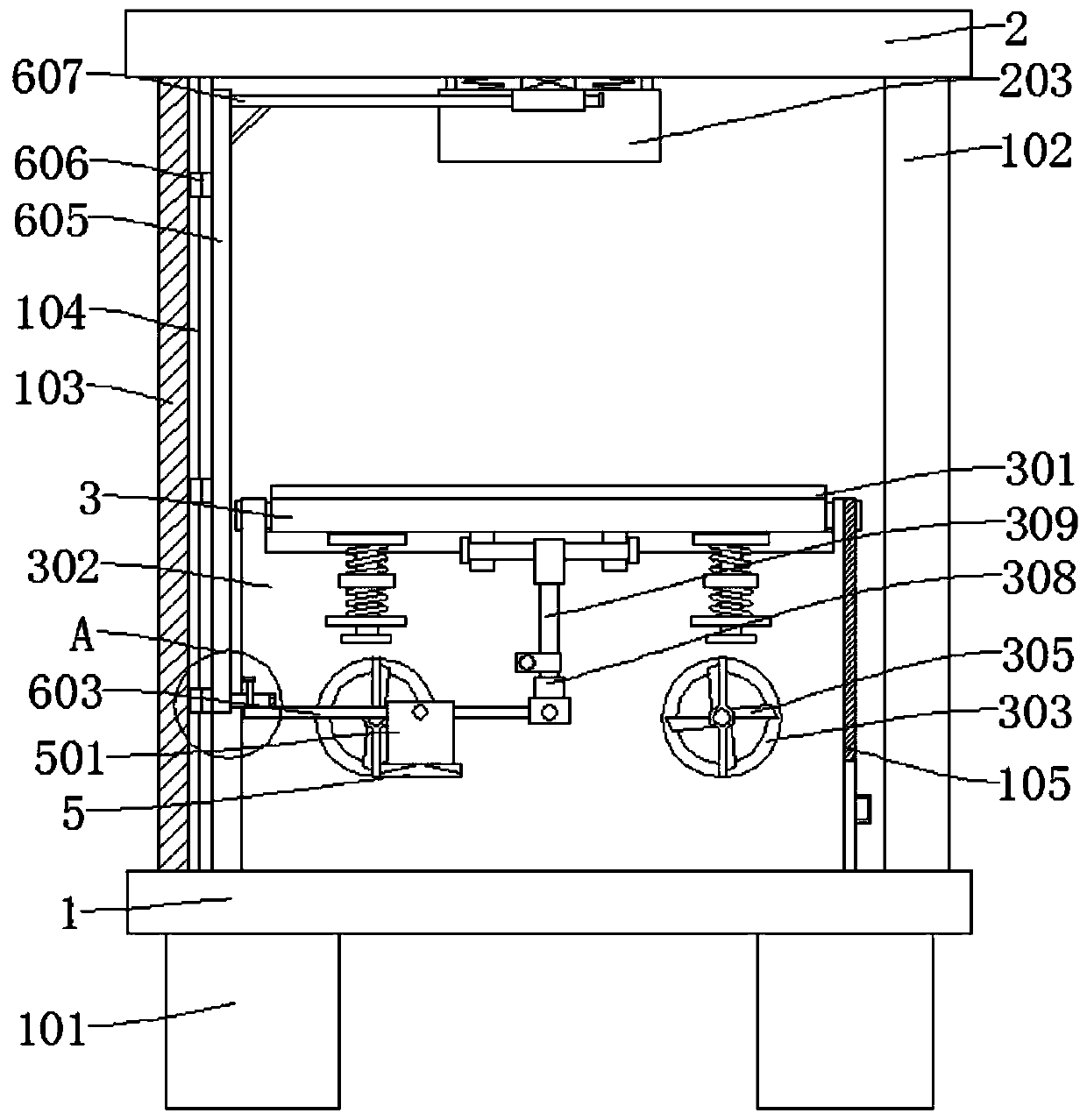

[0036] Reference figure 1 with figure 2 , A sawdust collection device for wood cutting, comprising a bottom plate 1. The top outer wall of the bottom plate 1 is respectively fixedly connected with a support rod 102 and a baffle 103, and the top outer walls of the support rod 102 and the baffle 103 are both connected with a top plate 2;

[0037] The top outer wall of the bottom plate 1 is also provided with a fixed plate 302. The top outer wall of the fixed plate 302 is provided with a circular arc groove. The working table 3 is connected to the circular arc groove through a rotating shaft. 3 is also provided with a through hole 304;

[0038] The bottom of the top plate 2 is provided with a groove 201, a sleeve 203 is rotatably connected in the groove 201, and a fan 207 is rotatably connected in the sleeve 203;

[0039] The outer wall of the sleeve 203 is provided with a push plate 208, one end of the push plate 208 away from the sleeve 203 is slidably connected with a push rod 605, ...

Embodiment 2

[0043] Reference Figure 1-7 , A sawdust collection device for wood cutting, comprising a bottom plate 1. The top outer wall of the bottom plate 1 is respectively fixedly connected with a support rod 102 and a baffle 103, and the top outer walls of the support rod 102 and the baffle 103 are both connected with a top plate 2;

[0044] The top outer wall of the bottom plate 1 is also provided with a fixed plate 302. The top outer wall of the fixed plate 302 is provided with a circular arc groove. The working table 3 is connected to the circular arc groove through a rotating shaft. The top of the working table 3 is provided with a limit frame 301. 3 is also provided with a through hole 304;

[0045] The bottom of the top plate 2 is provided with a groove 201, a sleeve 203 is rotatably connected in the groove 201, and a fan 207 is rotatably connected in the sleeve 203;

[0046] The outer wall of the sleeve 203 is provided with a push plate 208, one end of the push plate 208 away from th...

Embodiment 3

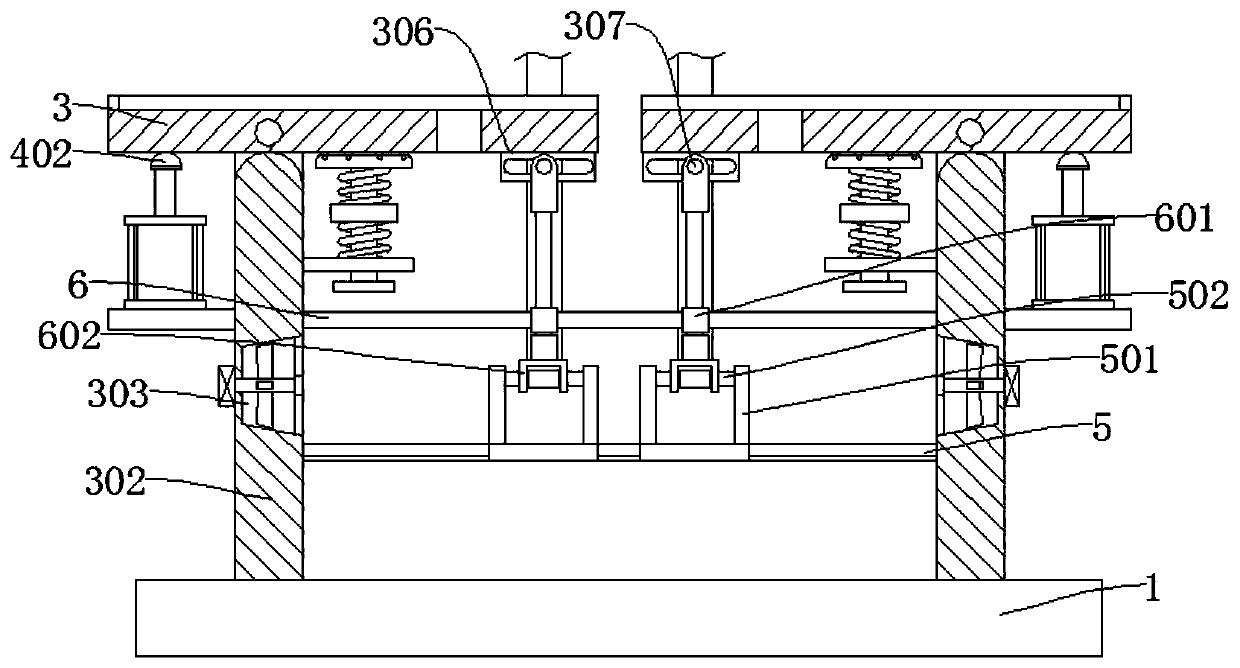

[0057] Reference Figure 1-7 , A sawdust collection device for wood cutting, which is basically the same as the embodiment 2. Furthermore, the inner wall of the fixed plate 302 is also connected with a second support plate 7, and the outer wall of the second support plate 7 is slidably connected with a sliding column. The top of the column is provided with a second pressing plate 702, the second pressing plate 702 is provided with a roller 704 that abuts the worktable 3, the outer wall of the sliding column is also slidingly connected with a first pressing plate 701, between the first pressing plate 701 and the second pressing plate 702 And a second spring 703 is connected between the first pressing plate 701 and the top outer wall of the second supporting plate 7, and the second spring 703 is sleeved on the outer wall of the sliding column.

[0058] The outer wall of the fixed plate 302 is provided with a first support plate 4, the top outer wall of the first support plate 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com