Cooling and shaping device for PE 100-grade polyethylene pipe production

A technology for cooling and forming polyethylene, applied in the field of cooling and forming devices for the production of PE100 polyethylene pipes, can solve the problems of poor pipe forming effect, slow cooling speed, uneven cooling of pipes, etc. Avoid the effect of uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

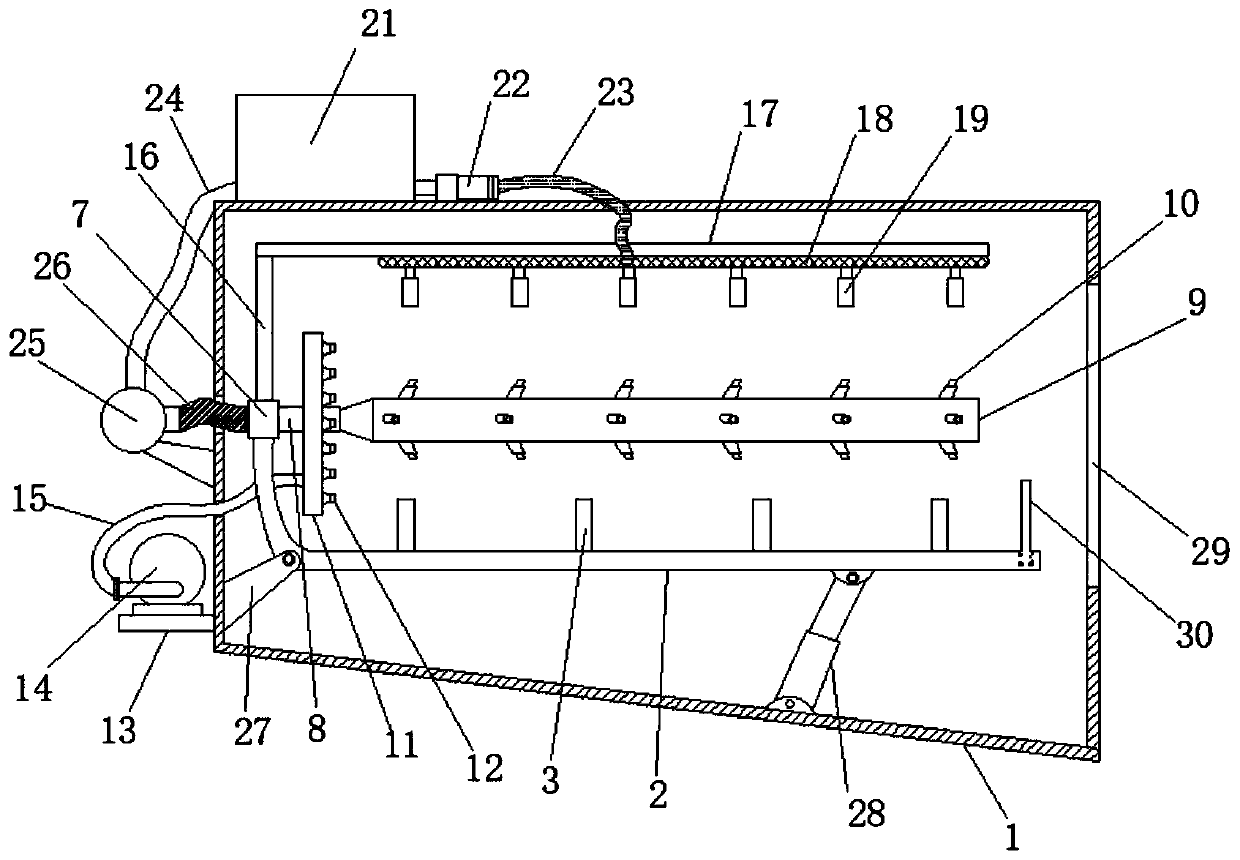

[0028] Attached below Figure 1-5 The present invention is further described with embodiment:

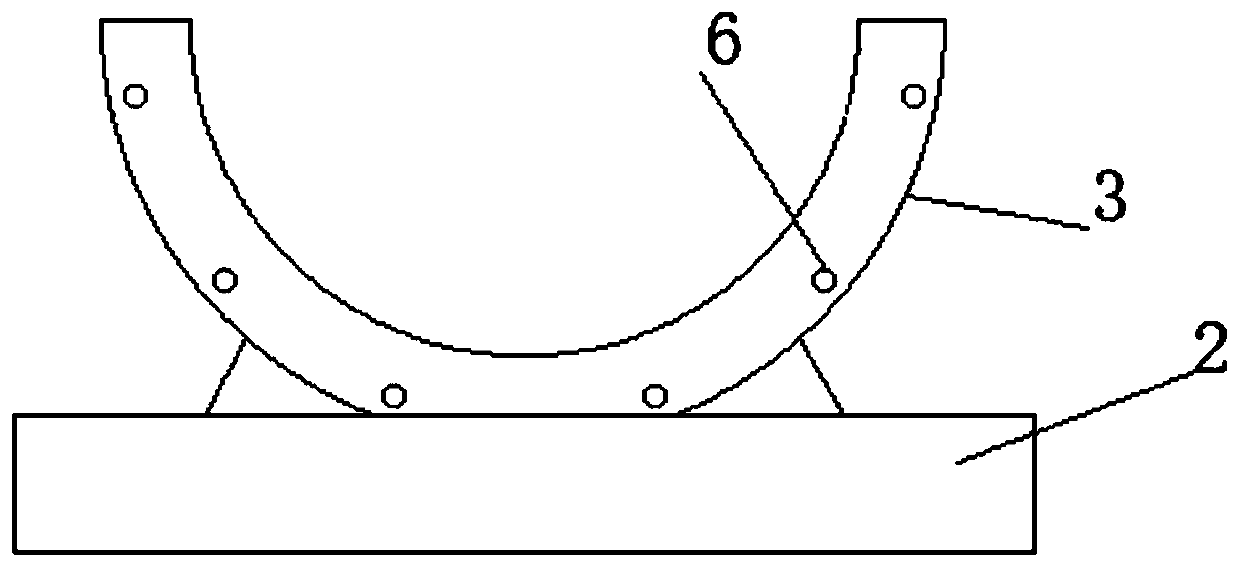

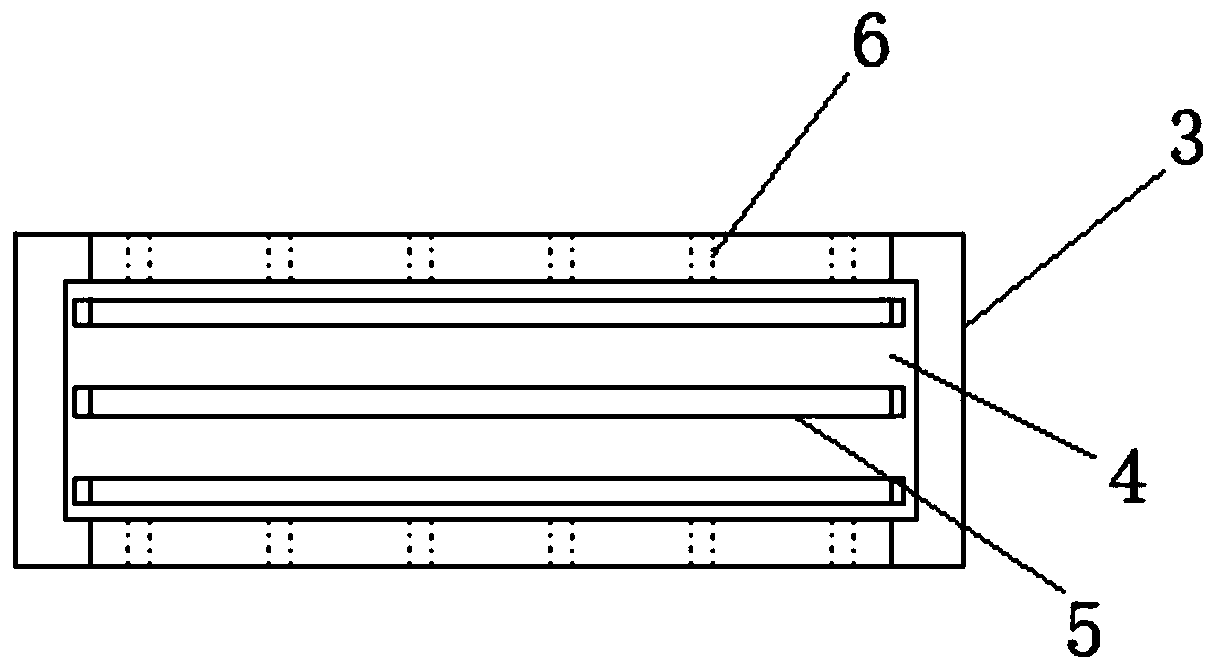

[0029] A cooling and shaping device for the production of PE100 grade polyethylene pipes, comprising a cooling box 1, a base plate 2 is provided at the inner bottom of the cooling box 1, and support plates 3 distributed equidistantly are provided at the top of the base plate 2, the support plates 3 is used to hold up the pipe, reduce the area covered by the bottom of the pipe, so as to facilitate cooling, the supporting plate 3 is an arc-shaped structure, and the inner concave surface of the supporting plate 3 is provided with a groove 4, the groove The inside of 4 is provided with a plurality of cooling fins 5, and the cooling fins 5 can further facilitate the heat dissipation and cooling of the pipe material. The outer walls of both sides of the supporting plate 3 are provided with drainage holes 6 to facilitate the discharge of sprayed water. One end of the supporting plate 3 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com