Quick-plug type automobile oil filling port box

A technology for a fuel filler and fuel filler cap, applied in the field of auto parts, can solve the problems of high requirements on the side surface difference of the whole vehicle, large investment in process steps, waste of cost, etc., so as to reduce the assembly cycle, simplify the assembly process, The effect of less investment in production hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

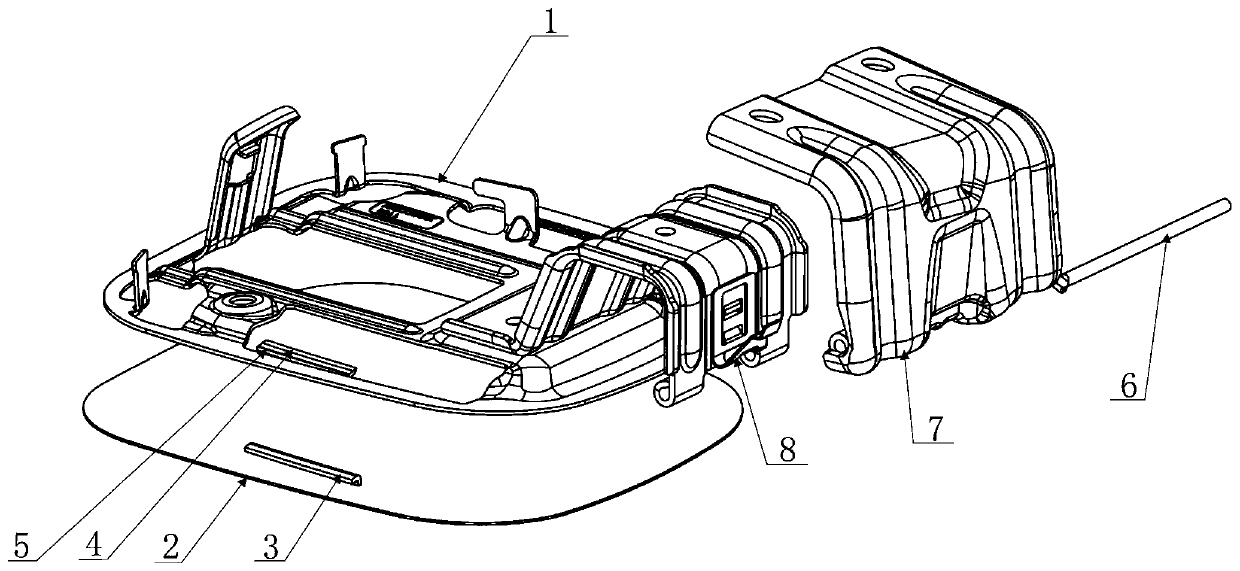

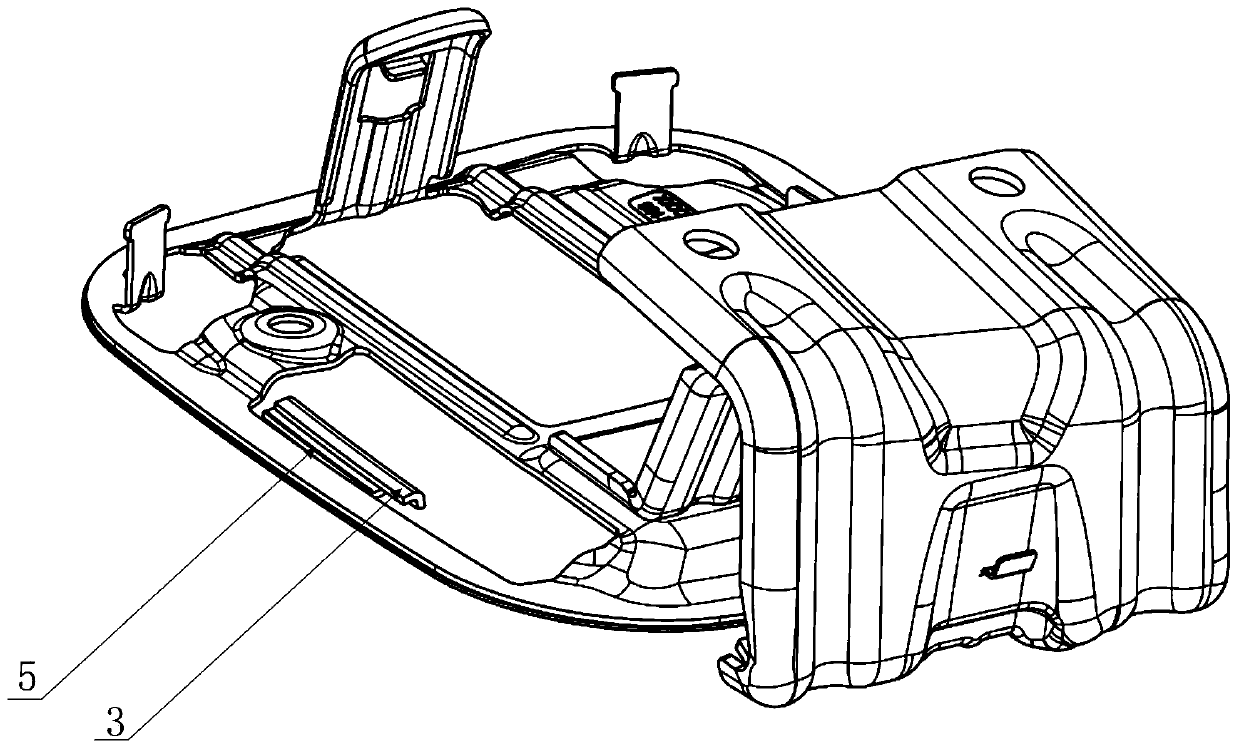

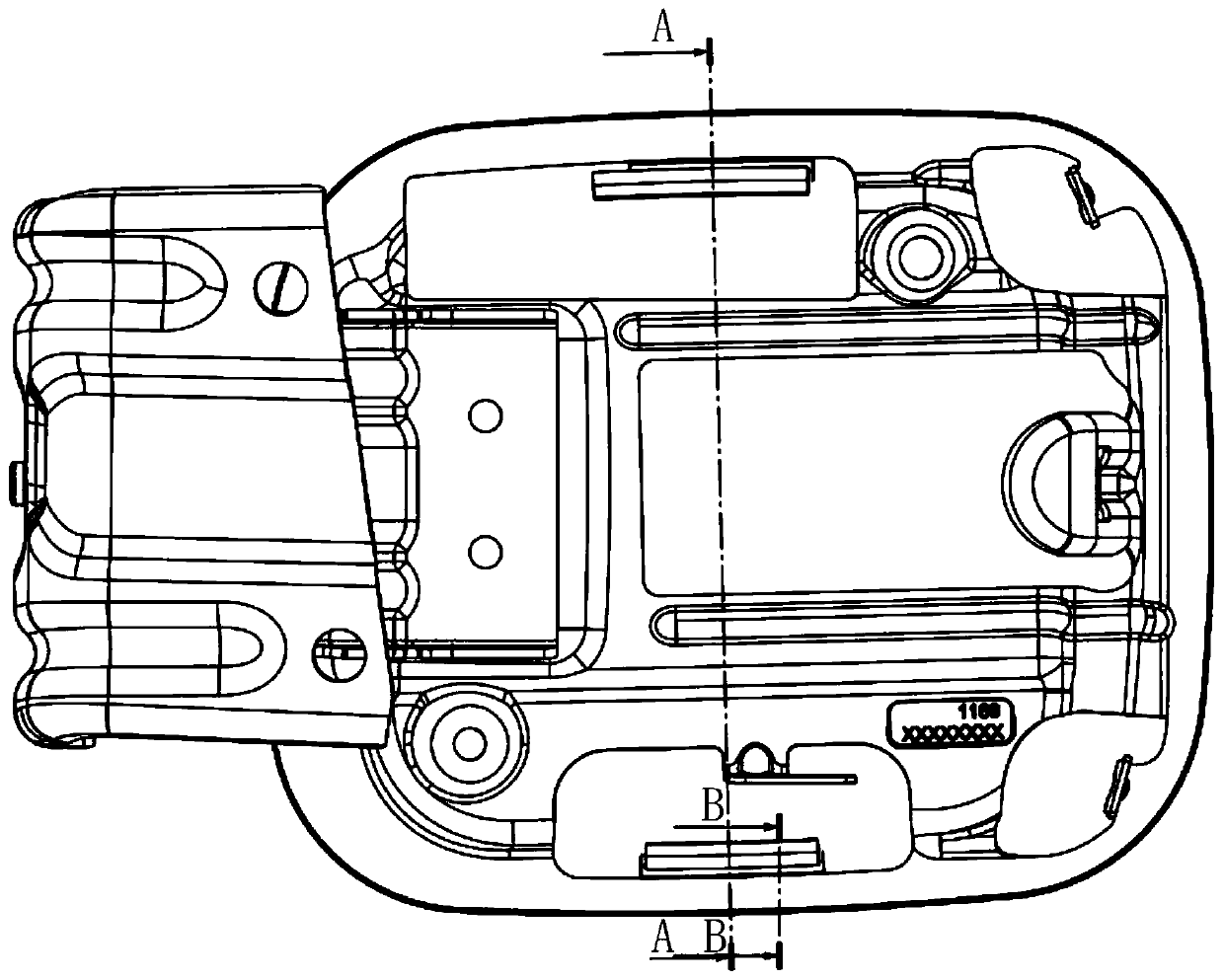

[0036] According to the attached Figure 1-6 A quick-plug type automobile fuel filler box according to an embodiment of the present invention is described in detail.

[0037] Such as Figure 1-6 As shown, the embodiment of the present invention discloses a quick-plug type automobile fuel filler box, comprising a fuel filler box and a fuel filler cap hinged with the fuel filler box; the fuel filler cap includes a fuel filler cap inner panel 1 and a fuel filler cap outer plate 2.

[0038] specific,

[0039] A first hook structure 3 is provided on the inner surface of the outer panel 2 of the fuel filler cap, and a through hole 4 through which the first hook structure 3 can pass is provided on the inner panel 1 of the fuel filler lid corresponding to the first hook structure 3 . The inner surface of the inner panel 1 of the fuel filler cap is also provided with a second hook structure 5 that can be closely fitted and hooked with the first hook structure 3 at the position below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com