Single-point mooring clamping jaw locking device

A locking device and mooring claw technology, applied in mooring equipment, transportation and packaging, ship parts, etc., can solve the problem of single-point mooring floating platform sinking, affecting the viability of offshore floating platform, and locking device loosening And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

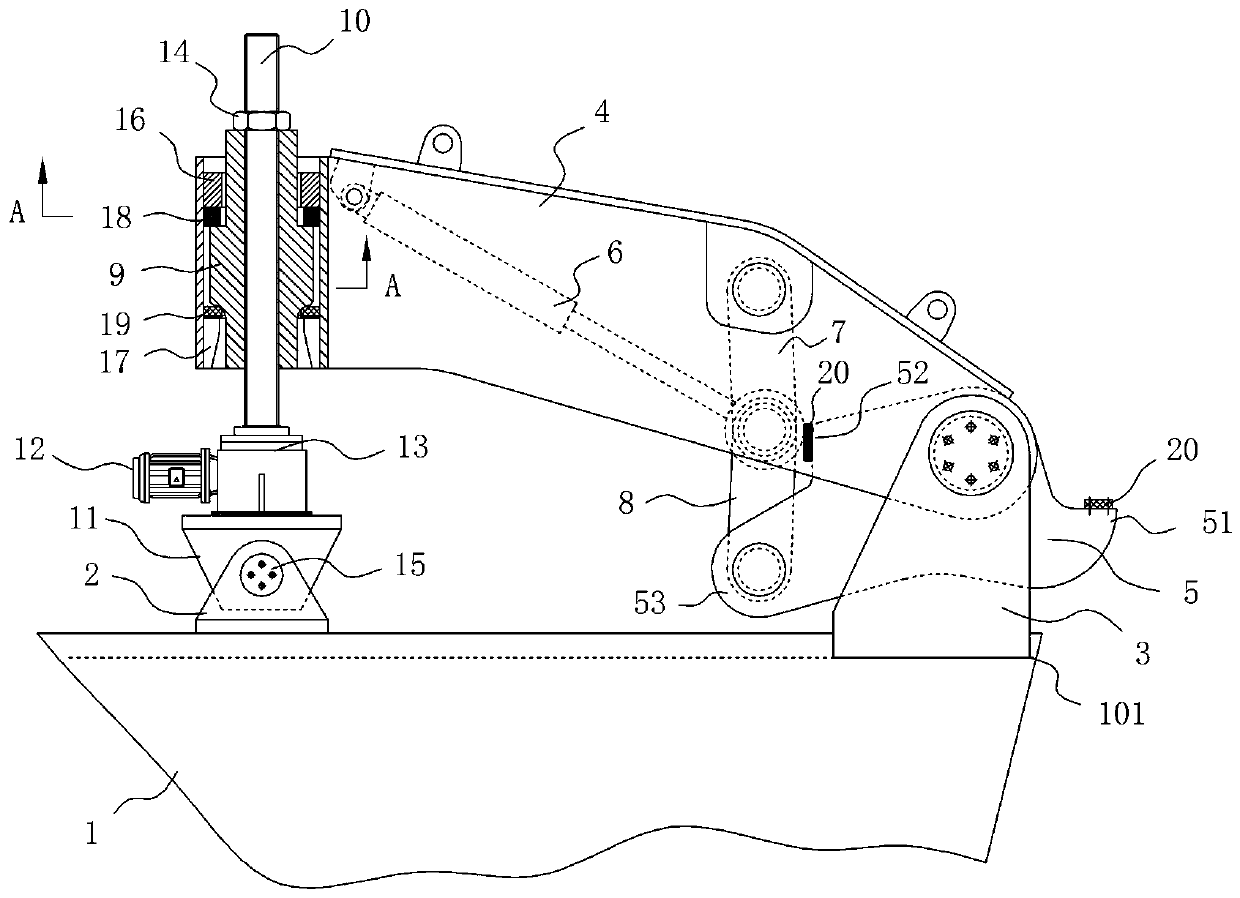

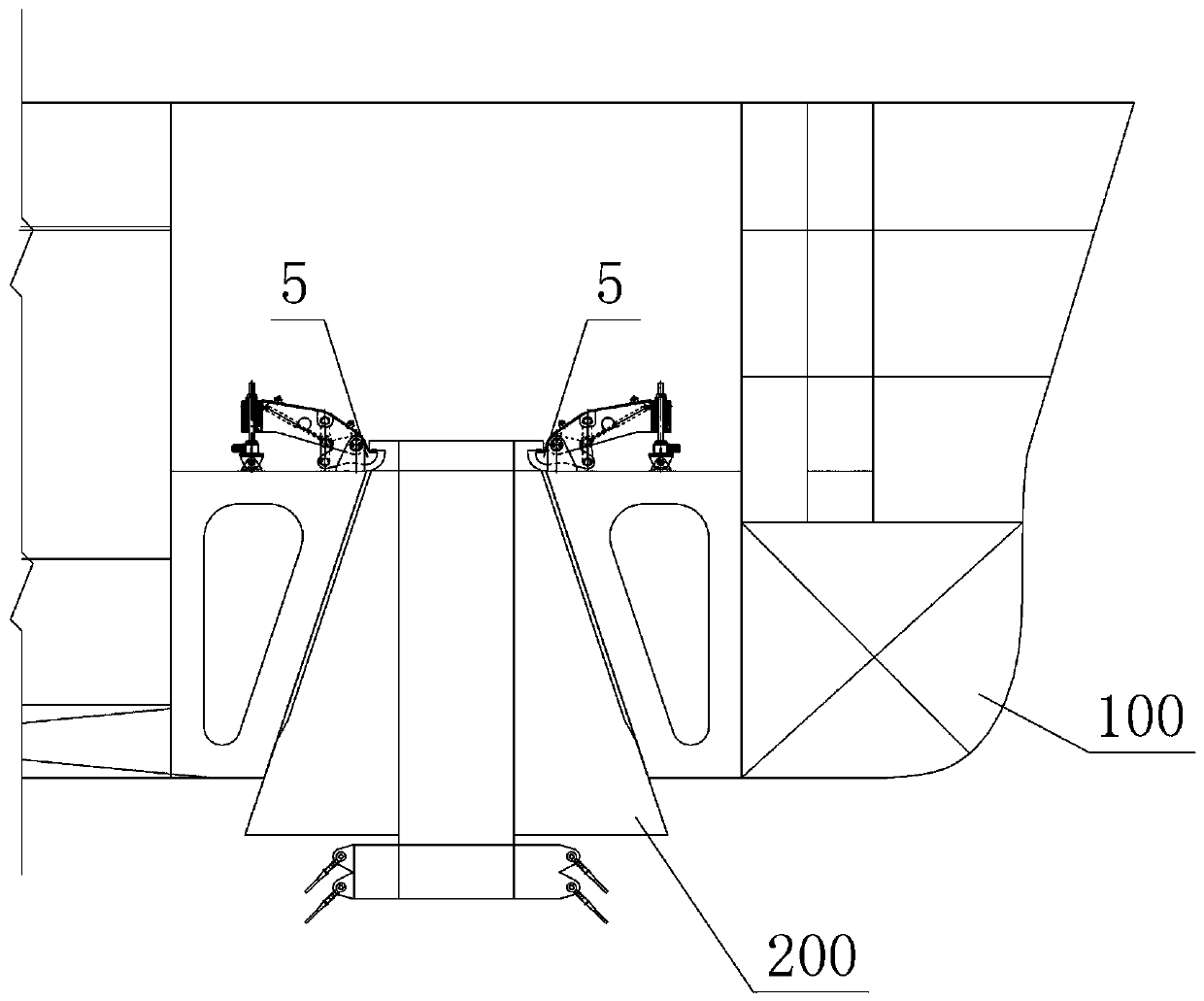

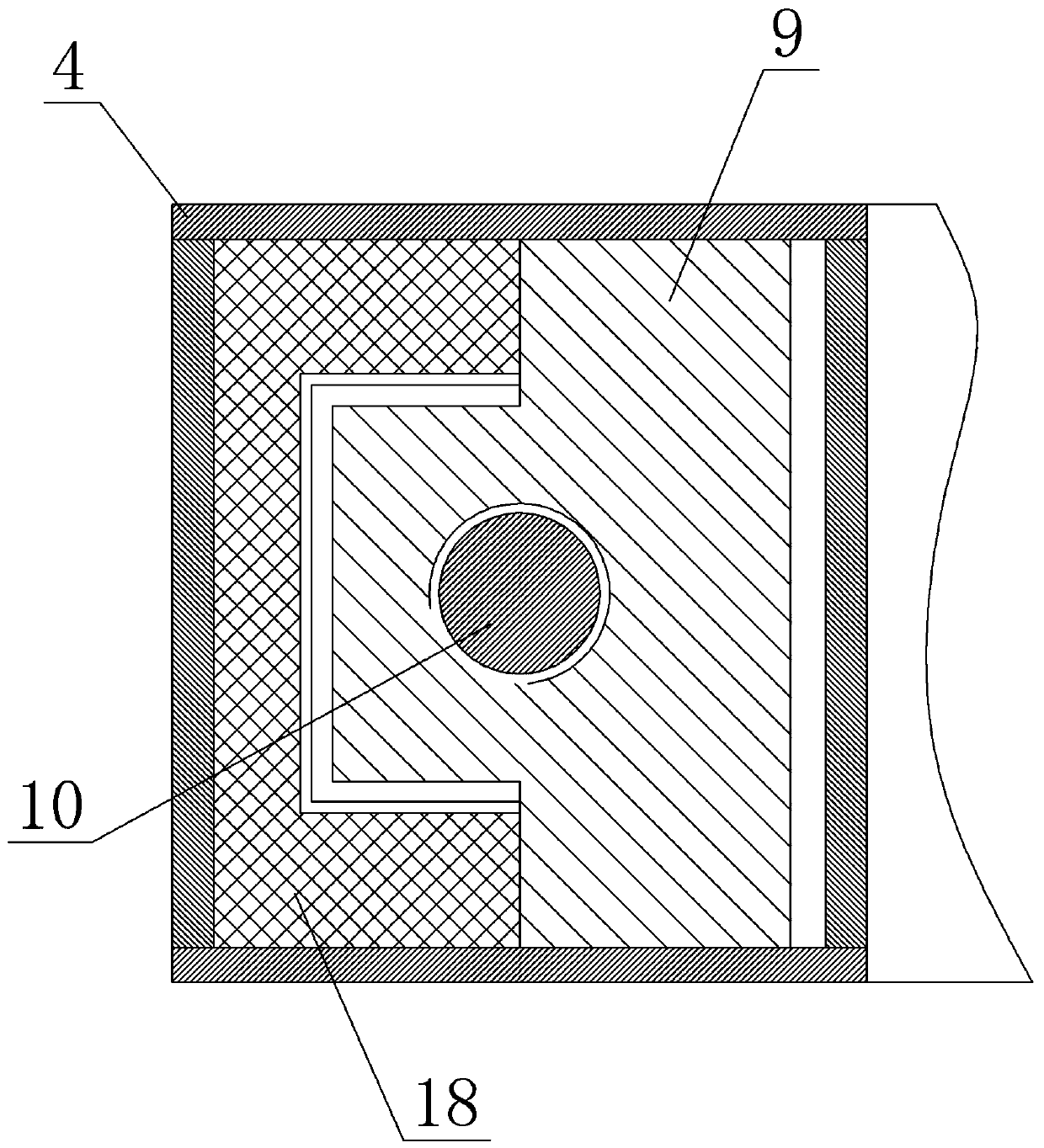

[0011] A single-point mooring claw locking device, comprising a base 2 and a base 3 fixedly installed on a base frame 1 of an offshore platform 100, an arm frame 4 is arranged between the base and the base, and one end of the arm frame is connected to the base Connection, the other end of the jib and the middle part of the claw 5 used to lock the mooring buoy 200 are hinged on the base at the same time, and the side of the claw facing away from the base is provided with a slot 201 that can be snapped into the mooring buoy In the clamping part 51, the upper and lower ends of the jaws facing the base are respectively provided with a tightening part 52 and a connecting part 53; there is also a telescopic driver 6 that is telescopic and one end is hinged on the side of the boom facing the base. 1. One end is hinged to the jib link 7 in the middle of the jib, one end is hinged to the jaw link 8 at the jaw joint, the telescopic drive, the other end of the jib link and the jaw link ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com