Annular belt assembly line device

A ring-shaped, flowing water technology, applied in conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as slow mechanical operation, falling, dust diffusion, etc., to increase sliding speed, increase stability, and avoid falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

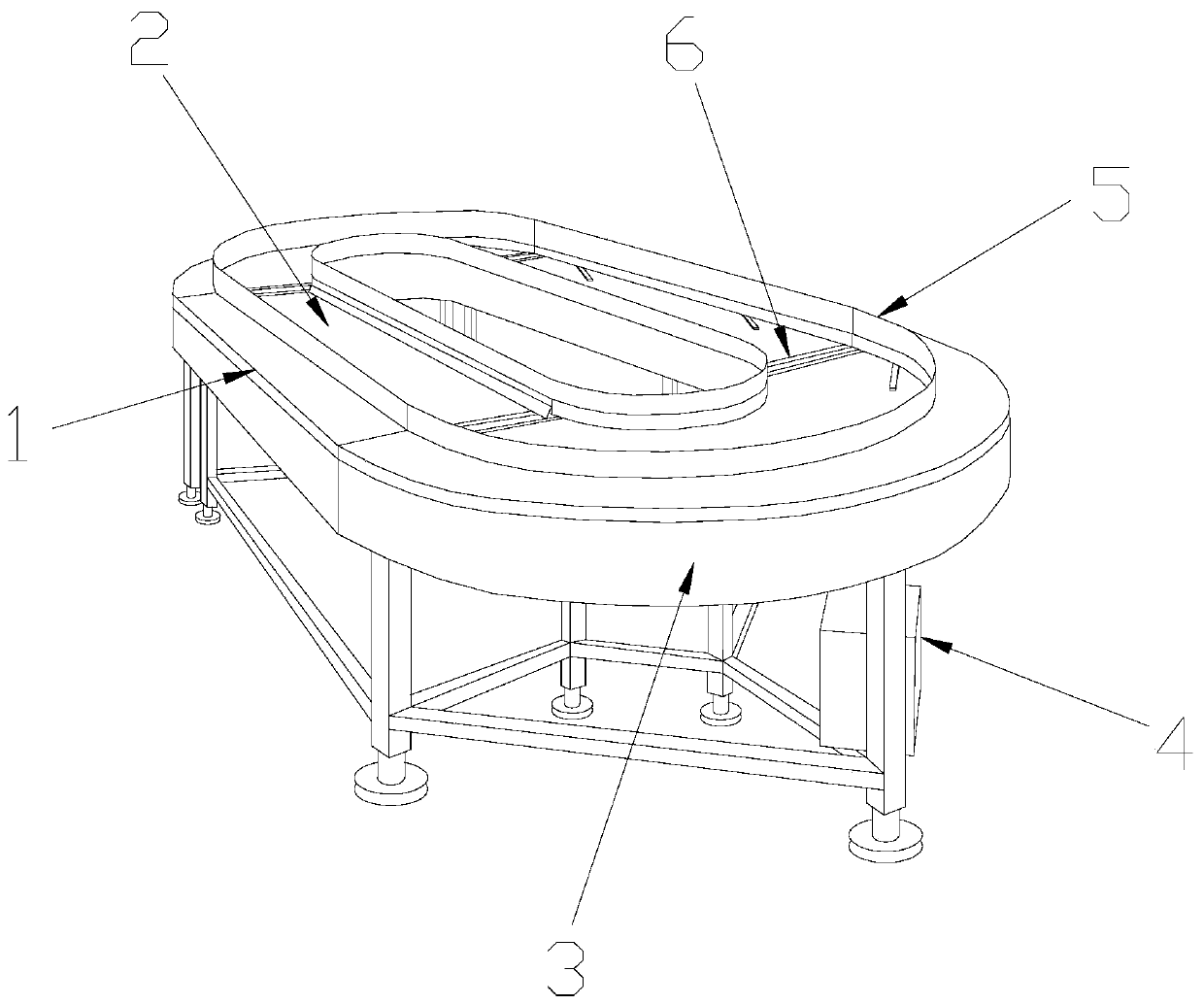

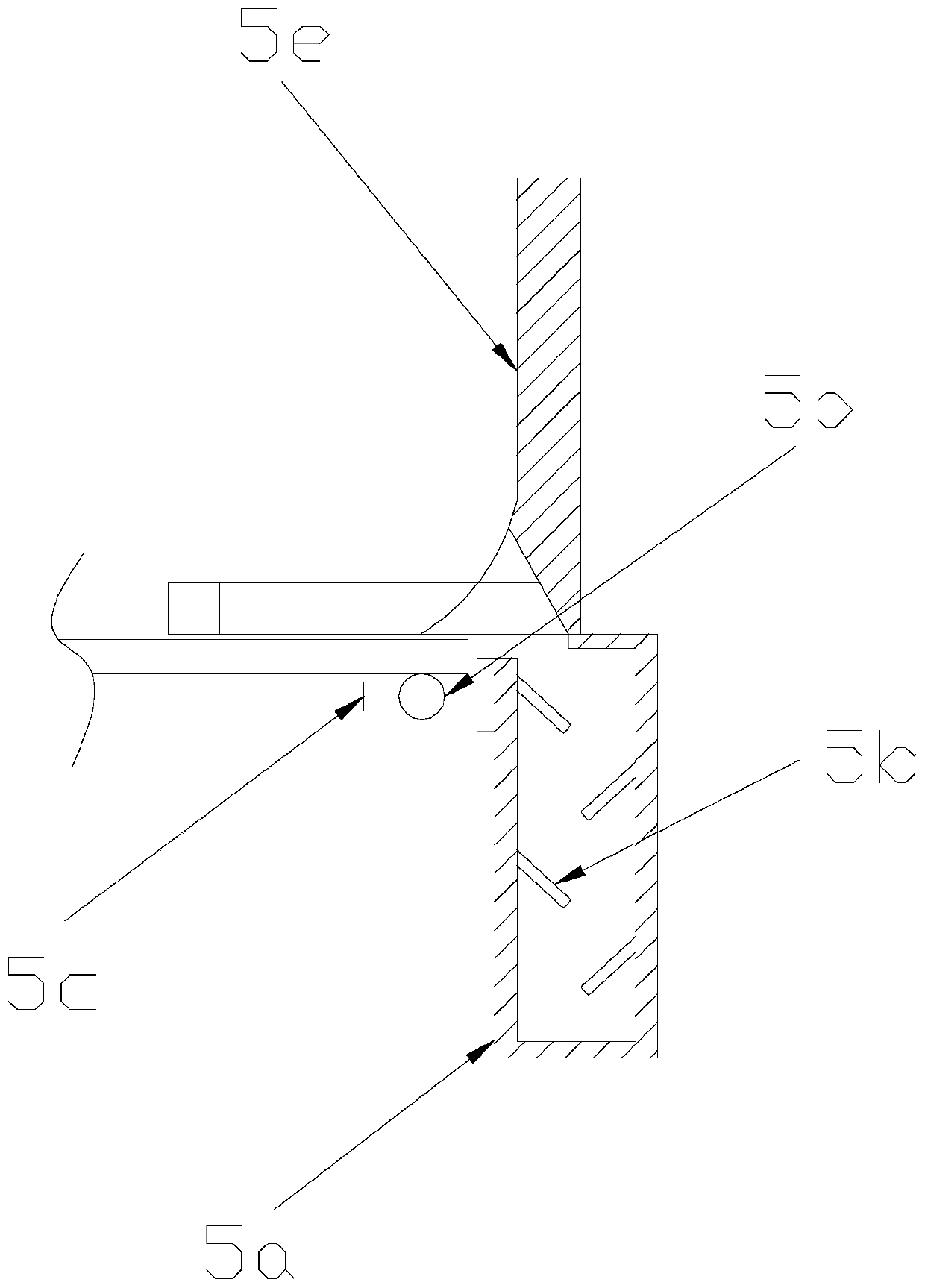

[0027] see Figure 1-Figure 6 , the present invention provides a ring-shaped belt flow equipment, the structure of which includes a linear conveyor 1, a conveyor belt 2, a curve conveyor 3, an electric controller 4, a chip collecting device 5, and a sliding mechanism 6. The linear conveyor The left and right ends of 1 are equipped with curved conveyors 3, the linear conveyor 1 and the curved conveyor 3 are movably connected by the sliding mechanism 6, and the two linear conveyors 1 and the two curved conveyors 3 form a ring structure, the electric controller 4 is provided under the curved conveyor 3, the curved conveyor 3 is connected to the electric controller 4, and the surface of the linear conveyor 1 and the curved conveyor 3 are equipped with transmission The belt 2, the surface of the linear conveyor 1 and the curved conveyor 3 are provided with a chip collecting device 5, and the linear conveyor 1 and the curved conveyor 3 are both movably connected with the chip collec...

Embodiment 2

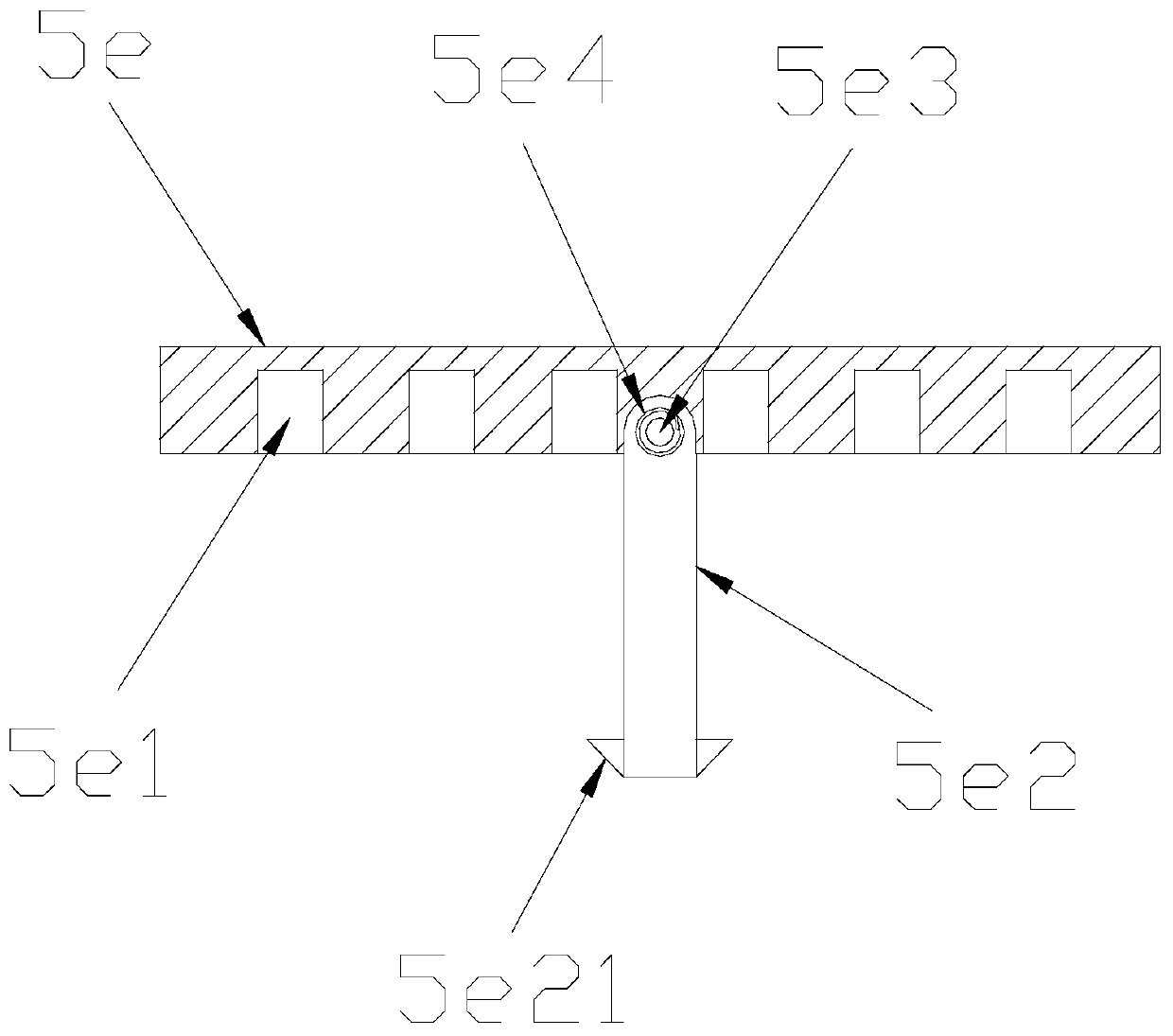

[0034] see Figure 1-Figure 6 , the present invention provides a ring-shaped belt flowing water equipment, the described sliding aid mechanism 6 is composed of a second debris collecting box 6a, an anti-backflow mechanism 6b, a support ear 6c, a second rotating shaft 6d, and a sliding aiding guide roller 6e, the described Two pairs of support ears 6c are provided on the top of the second dust collection box 6a, the second dust collection box 6a and the support ears 6c are fixedly connected, and an anti-backflow mechanism 6b is installed inside the second dust collection box 6a, The left and right ends of the sliding guide roller 6e are provided with a second rotating shaft 6d, the sliding guiding roller 6e and the second rotating shaft 6d are welded by electric welding, and the supporting ear 6c is provided with a sliding guiding roller 6e , the support ear 6c and the sliding guide roller 6e adopt clearance fit through the second rotating shaft 6d.

[0035] The anti-backflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com