Hanging scaffold device

A hanging plate and pressure plate technology, which is applied in the field of enameled wire manufacturing equipment, can solve problems such as manual correction, unstable grasping, and large space occupation, so as to meet high-speed production needs, reduce parts costs, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

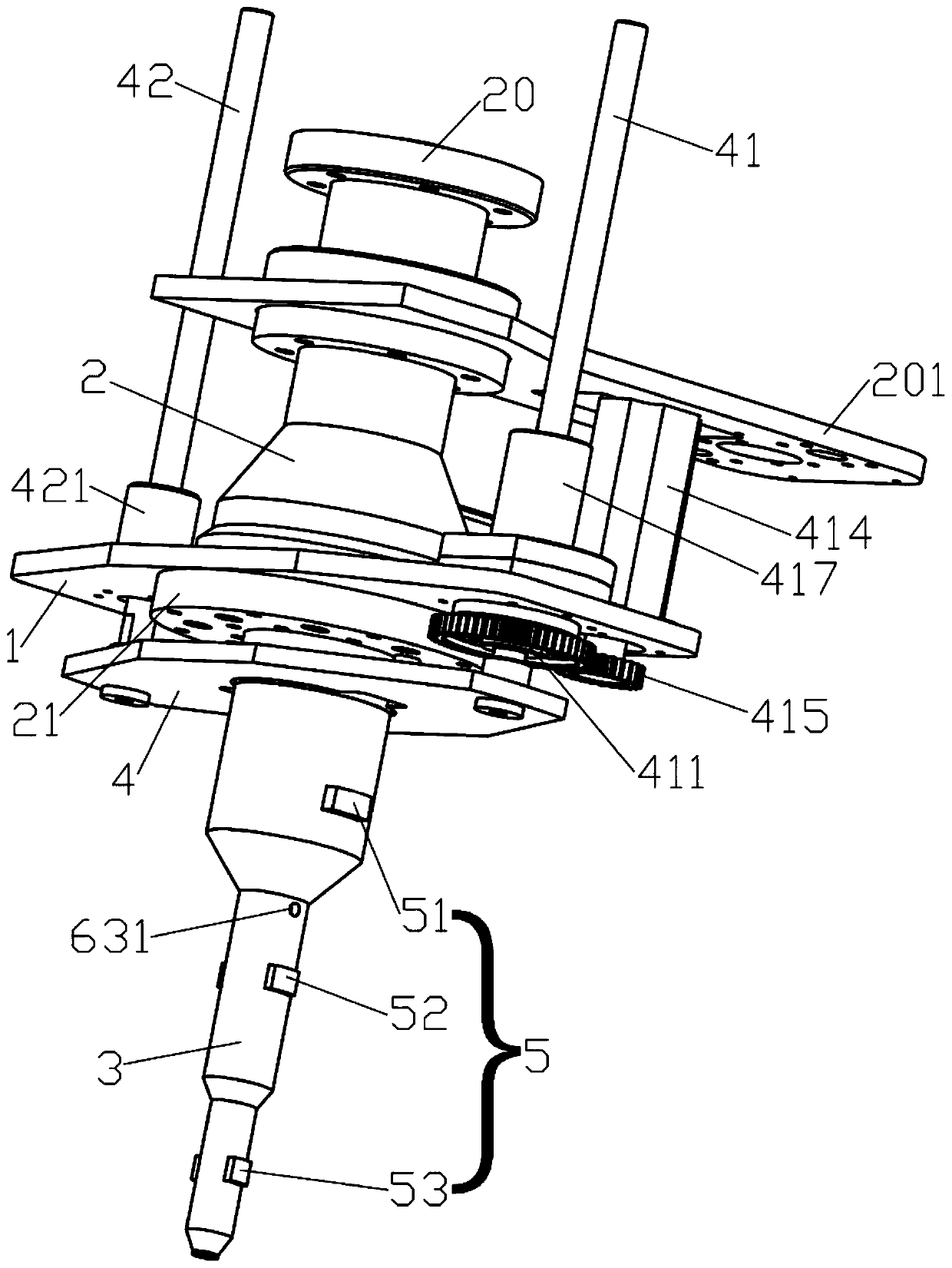

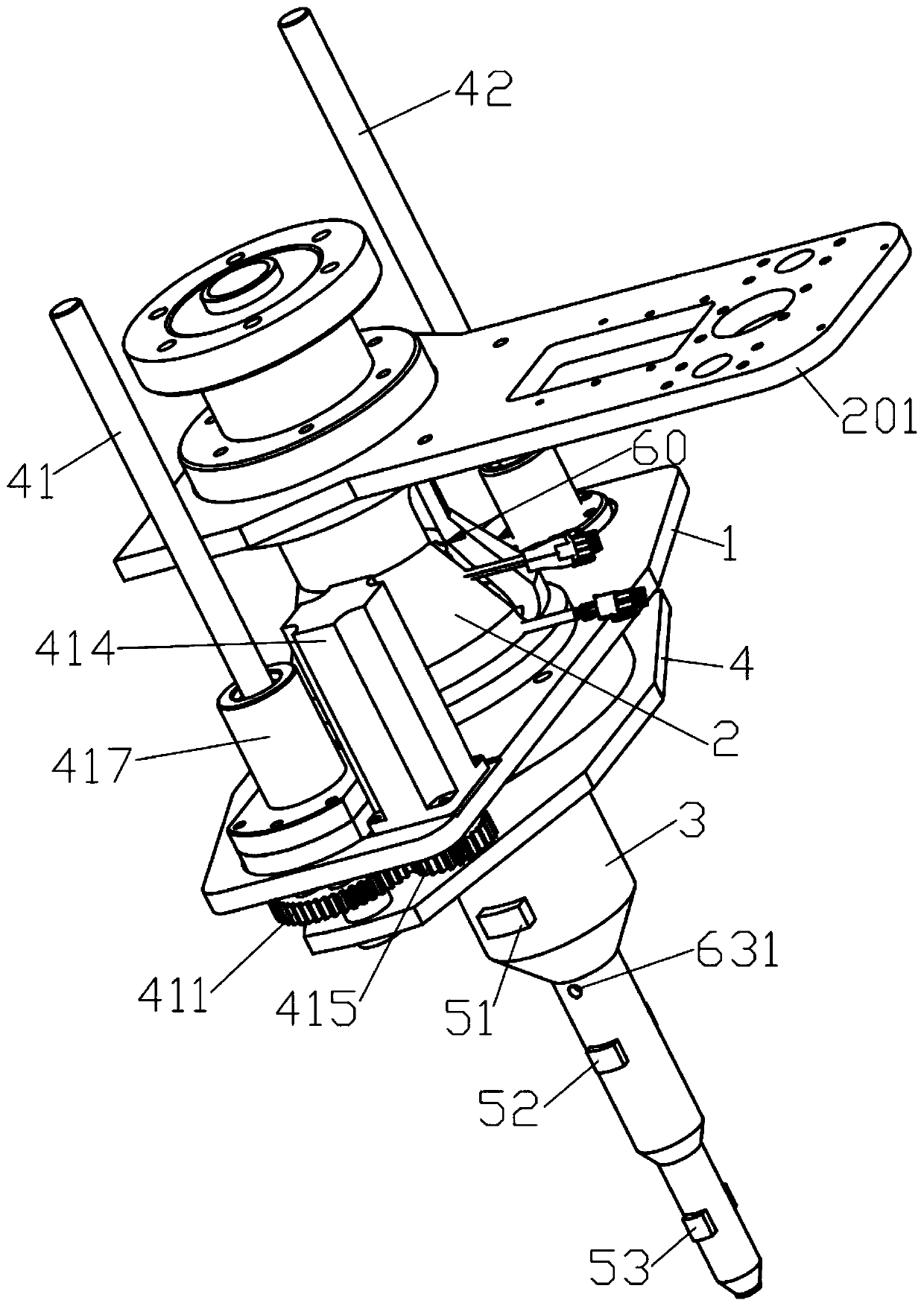

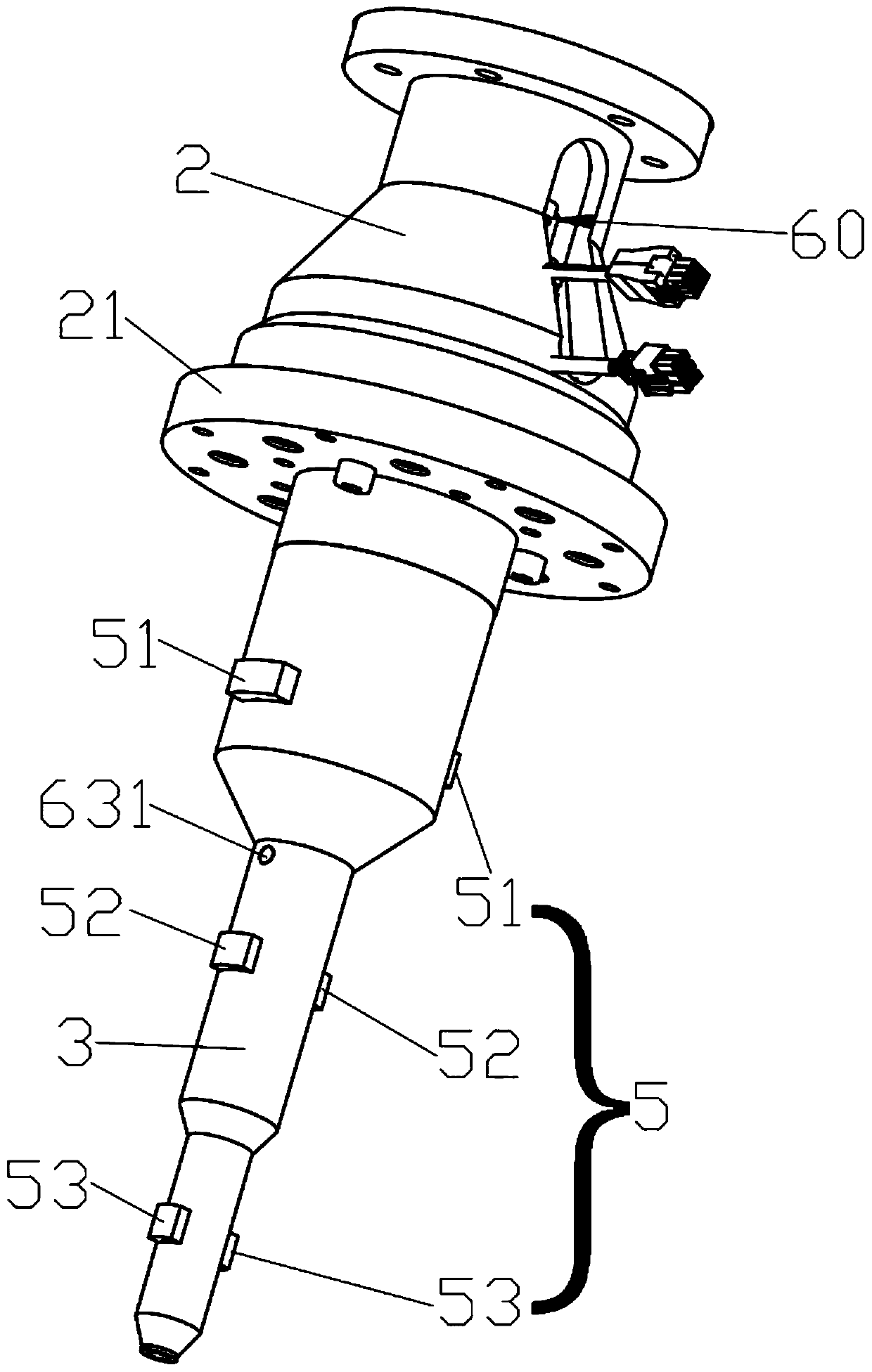

[0026] Such as figure 1 and 2 As shown, a hanging pan device according to an embodiment of the present invention includes a base plate 1 , a fixing sleeve 2 , a hanging pan shaft 3 and a pan holding plate 4 . A base 201 is fixedly connected to the top of the fixed sleeve 2 by bolts, and a fixed sleeve positioning ring 20 is installed on the base 201 by bolts. The fixed sleeve positioning ring 20 is convenient for connecting the manipulator in the later stage, so as to realize the connection between the suspension device and other equipment. fit of parts. The fixed sleeve 2 is a hollow structure, the upper part of the suspension pan shaft 3 is connected to the bottom of the fixed sleeve 2, and the outer wall of the suspension pan shaft 3 is provided with a hinge block assembly 5 which can be extended or retracted, so as to hook up the pan. The fixing sleeve 2 is installed on the outside and fixed to the base plate 1 by bolts. The plate holding plate 4 is set on the outside of...

Embodiment 2

[0033] Such as Figure 7 and 8 As shown, the main difference between the hanging pan device described in Embodiment 2 and Embodiment 1 is that the control shaft driver 60 for driving the control shaft 6 and the elevating mechanism for driving the plate tool pressure plate 4 are different. In this embodiment, pneumatic control is mainly used.

[0034] Such as Figure 8 and 9 As shown, the control shaft driving part 60 is a cylinder 60B, the cylinder body of the cylinder 60B is installed on the top of the suspension shaft 3 through the end cover assembly 22, the piston rod of the cylinder 60B is connected to the top of the control shaft 6, and the cylinder body of the cylinder 60B is located on a fixed Set 2 inside. When the cylinder 60B is used as the control shaft driving member 60, the up and down movement of the control shaft 6 relative to the suspension pan shaft 3 is realized through the expansion and contraction of the piston rod of the cylinder 60B. Specifically, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com