A kind of putty powder and preparation method thereof

A technology of putty powder and stone powder, which is applied in the direction of filling slurry, etc., can solve the problems that the hardness, washing resistance, tensile strength and crack resistance cannot meet the requirements, and can not completely solve the problem of pulverization, so as to improve the sag resistance and slip resistance, increased flow properties, and smooth coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

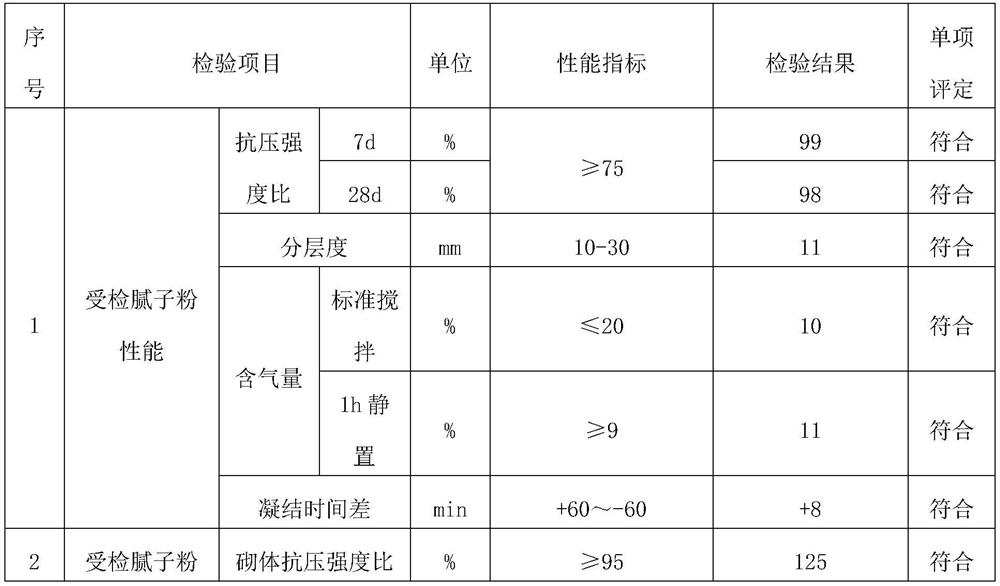

Embodiment 1

[0060] The raw materials of the putty powder in this embodiment include the following components in parts by weight:

[0061] 200 parts of stone powder, the particle size of the stone powder is 200 mesh;

[0062] 50 parts of sodium bentonite;

[0063] 5 parts of sodium alginate, the dispersibility index of the sodium alginate is 1.5;

[0064] 40 parts of etherified starch;

[0065] 15 parts of carboxymethyl cellulose, the viscosity of the carboxymethyl cellulose is 200~1200;

[0066] 10 parts of polyvinyl alcohol powder;

[0067] 2 parts calcium chloride powder;

[0068] 10 parts of borax, the particle size of the borax is 200 mesh.

[0069] The preparation method of putty powder described in the present embodiment may further comprise the steps:

[0070] (1) Accurately weigh each raw material according to parts by weight;

[0071] (2) adding each raw material except calcium chloride into water, and mixing uniformly;

[0072] (3) Pour the mixed solution in step (2) into ...

Embodiment 2

[0079] The raw materials of the putty powder in this embodiment include the following components in parts by weight:

[0080] 500 parts of stone powder, the particle size of the stone powder is 300 mesh;

[0081] 80 parts of sodium bentonite;

[0082] 20 parts of sodium alginate, the dispersibility index of the sodium alginate is 1.5;

[0083] 75 parts of etherified starch;

[0084] 65 parts of carboxymethyl cellulose, the viscosity of the carboxymethyl cellulose is 200~1200;

[0085] 100 parts of polyvinyl alcohol powder;

[0086] 30 parts of calcium chloride powder;

[0087] 15 parts of borax, the particle size of the borax is 200 mesh.

[0088] The preparation method of putty powder described in the present embodiment may further comprise the steps:

[0089] (1) Accurately weigh each raw material according to parts by weight;

[0090] (2) adding each raw material except calcium chloride into water, and mixing uniformly;

[0091] (3) Pour the mixed solution in step (...

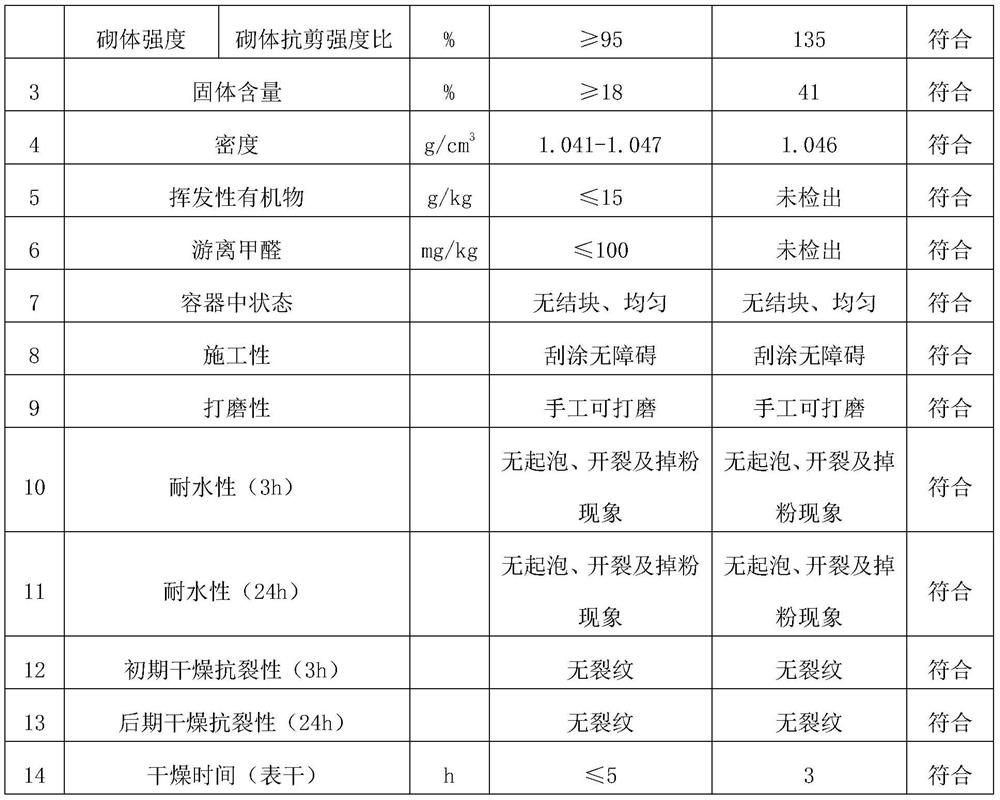

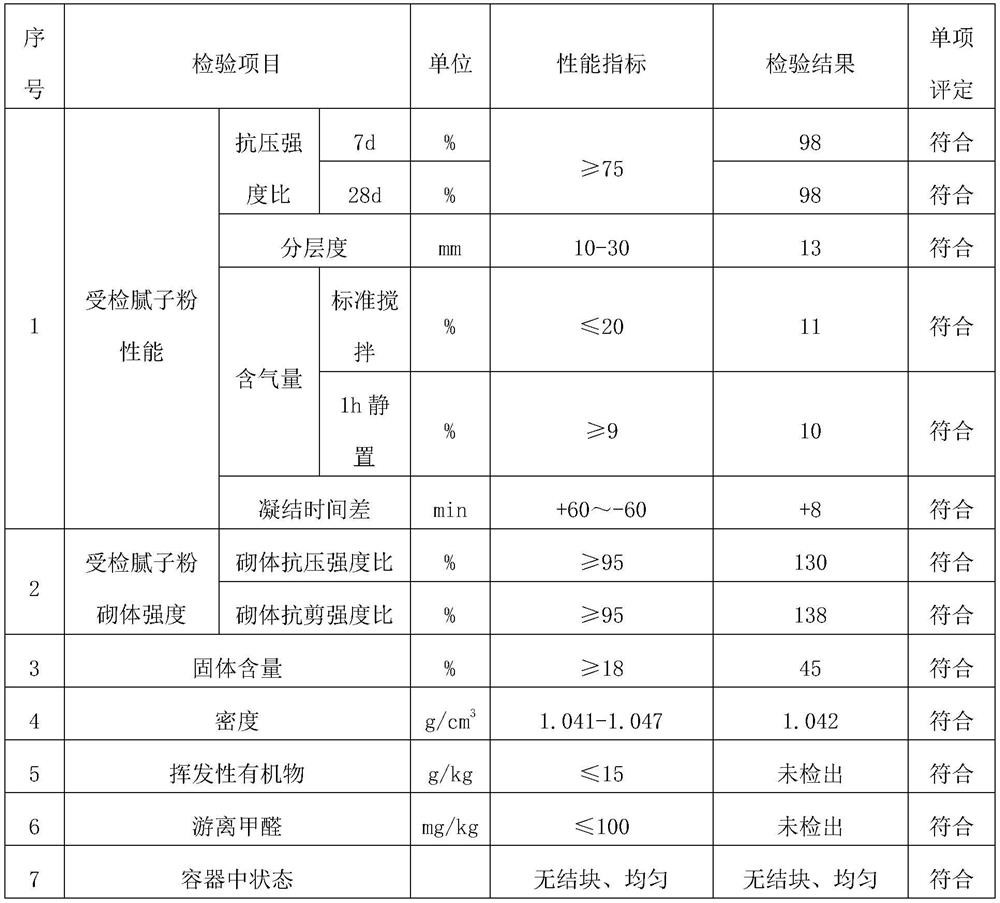

Embodiment 3

[0097] The raw materials of the putty powder in this embodiment include the following components in parts by weight:

[0098] 300 parts of stone powder, the particle size of the stone powder is 200 mesh;

[0099] 60 parts of sodium bentonite;

[0100] 15 parts of sodium alginate, the dispersibility index of the sodium alginate is 2;

[0101] 50 parts of etherified starch;

[0102] 25 parts of carboxymethyl cellulose, the viscosity of the carboxymethyl cellulose is 200~1200;

[0103] 30 parts of polyvinyl alcohol powder;

[0104] 13 parts of calcium chloride powder;

[0105] 12 parts of borax, the particle size of the borax is 250 mesh.

[0106] The preparation method of putty powder described in the present embodiment may further comprise the steps:

[0107] (1) Accurately weigh each raw material according to parts by weight;

[0108] (2) adding each raw material except calcium chloride into water, and mixing uniformly;

[0109] (3) Pour the mixed solution in step (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap