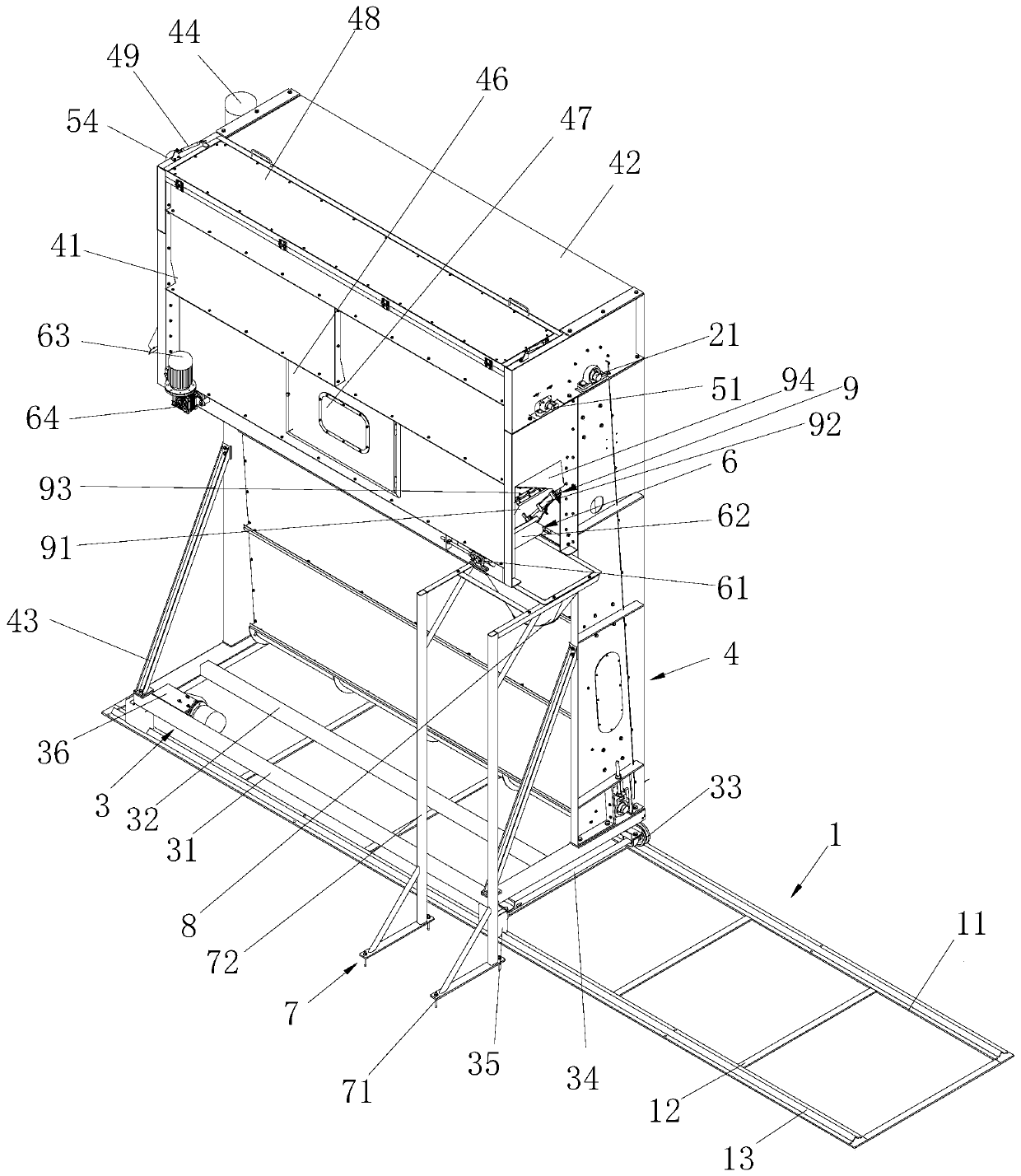

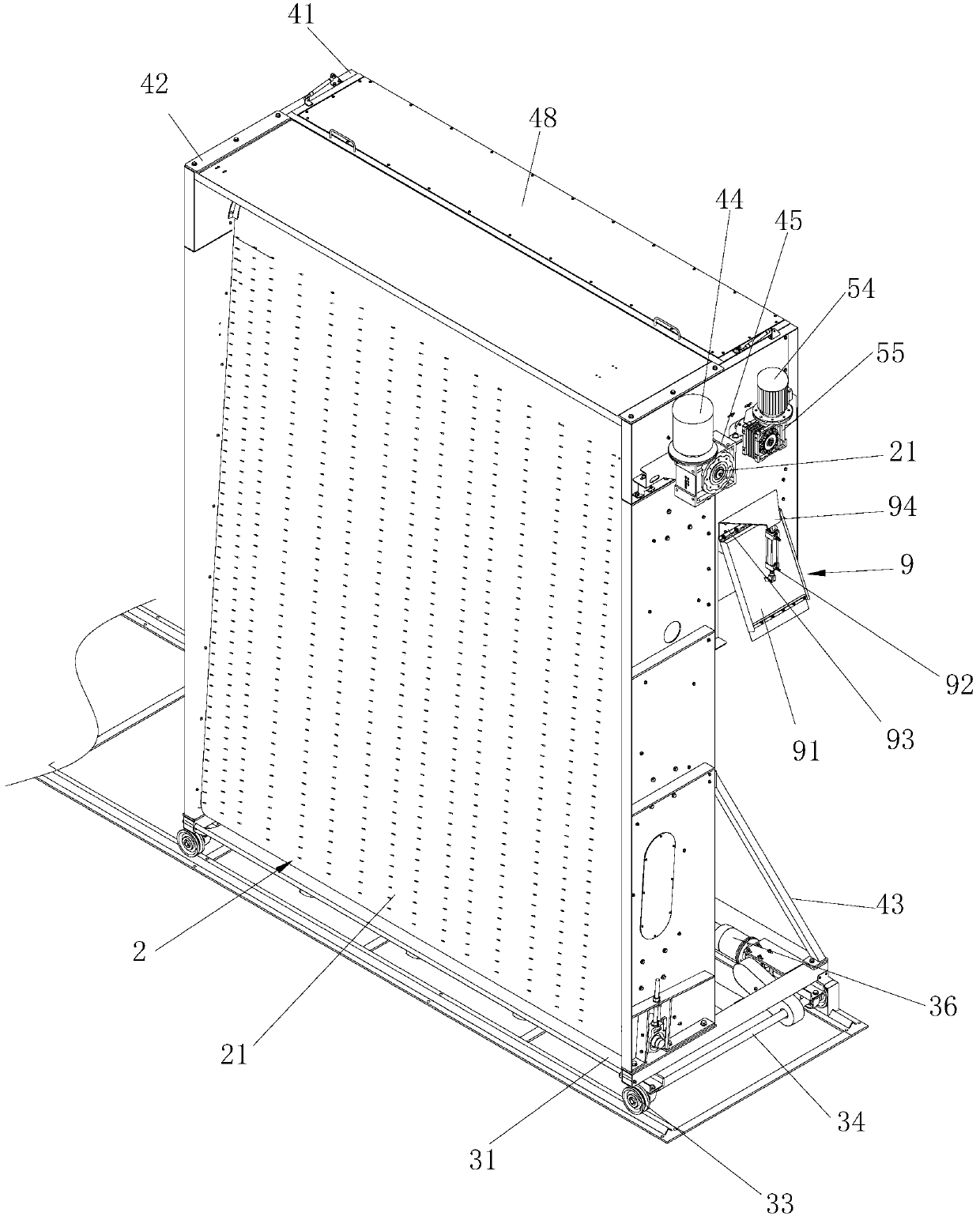

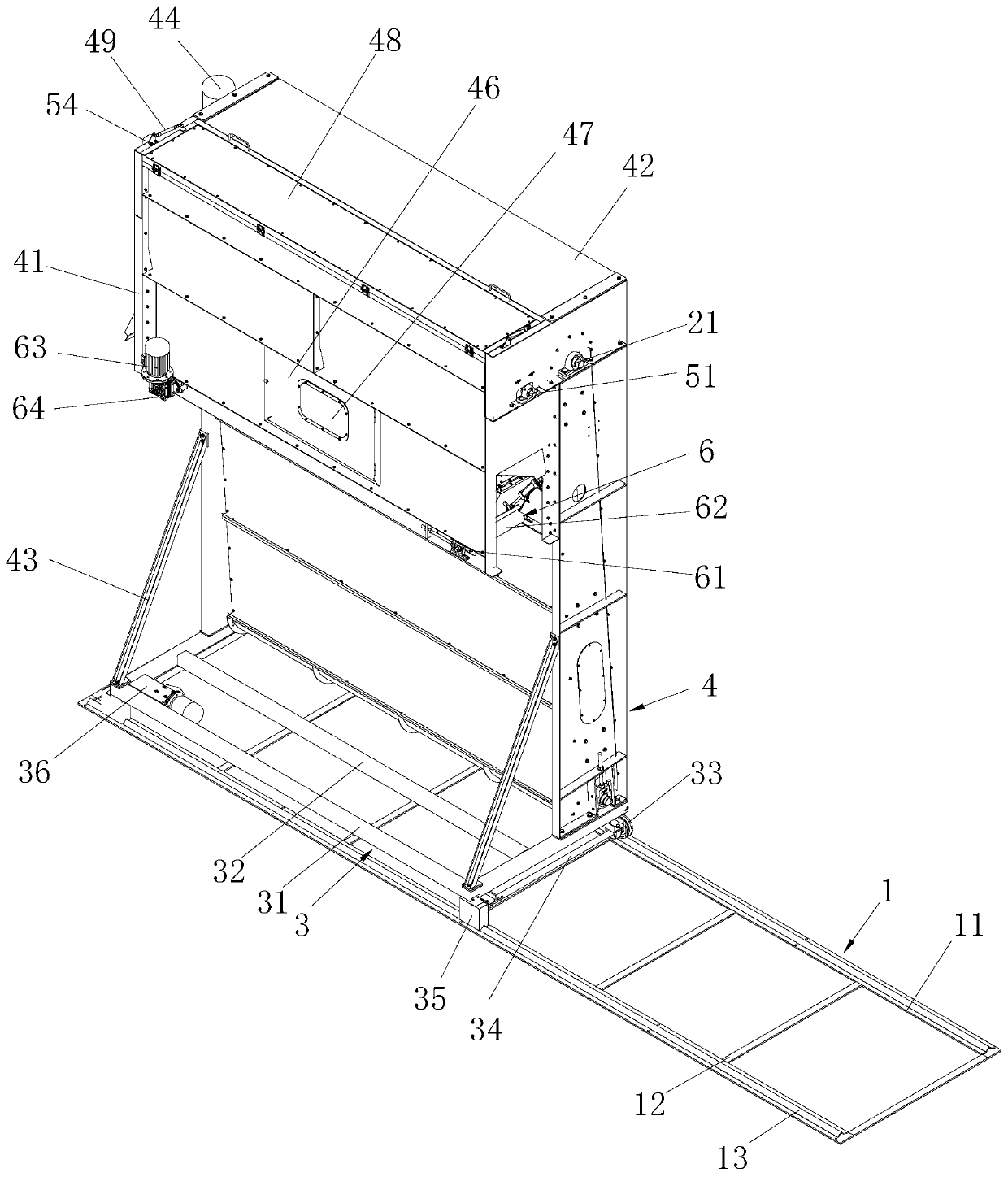

Wool fiber elevating and collecting device

A collection device and wool fiber technology, applied in fiber processing, fiber feeding, fiber mixing, etc., can solve the problems of inconvenience and installation inconvenience, potential safety hazards of oblique nail curtains, and low collection efficiency. Achieve the effects of convenient observation, simple and novel structure, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0067] The above-mentioned wool fiber lifting and collecting device is used in conjunction with the wool bin 101 in the wool machine in the prior art. There are two wool bins in the wool bin. The wool fiber lifting and collecting device can be separated more smoothly and efficiently. Lift and collect the wool fibers in the two wool bins.

[0068] In the wool fiber lifting collection device, a first base frame 1, a first support frame and a lifting support shell for supporting are first provided, and the first base frame 1 is provided with a sliding rail for the first support frame and the lifting support shell 4 to slide , Through the sliding support of the slide rail, the wool fiber collecting and lifting collecting device can move and lift the wool fiber in different warehouses more conveniently. When the wool fiber is lifted, the oblique nail curtain mechanism 2 lifts the wool fiber in the bottom flat curtain upper chamber to the front part of the lifting support shell 4. The...

Embodiment 3

[0072] The above-mentioned wool fiber lifting and collecting device can carry out the lifting and collecting of the wool fiber of the two wool bins of the two wool bins more efficiently, smoothly and safely. After the first and wool compartment is filled with wool fibers, the wool fiber lifting and collecting device lifts the wool fibers in the first and wool compartment, and then the second and wool compartment can be filled with wool fibers. After the wool fiber in the first and wool compartment is lifted, the wool fiber lifting and collecting device can then lift and collect the wool fiber in the filled second and wool compartment. At this time, the first and wool compartment The chamber is then filled with wool fibers. Through this alternate filling and lifting collection work, the wool fiber lifting and collecting device can always perform efficient lifting and collecting, which is different from the lifting and collecting of single and wool bins in the prior art.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com