Vibration pile machine for immersed tube sand-gravel pile and pile forming method

A technology for sand and gravel piles and pile drivers, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of reduced diameter pile quality, poor diameter reduction and pile quality, broken piles, etc., so as to reduce broken piles. The probability of occurrence, the effect of improving the quality of piles and improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

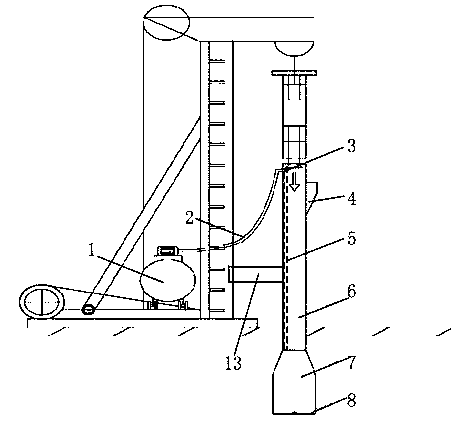

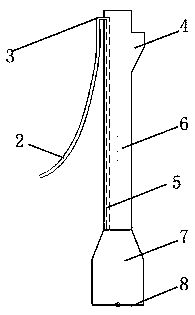

[0048] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

[0049] In view of the problems existing in the prior art, the present invention provides a vibrating pile machine and a method for forming a pile for sunk pipe gravel piles. The present invention will be described in detail below with reference to the accompanying drawings.

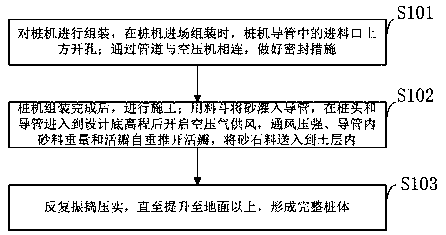

[0050] Such as figure 1 As shown, the method for forming a pile by a vibrating pile machine for a sunken sand-gravel pile provided by an embodiment of the present invention includes the following:

[0051] S101: Assemble the pile driver. When the pile driver is assembled, make a hole above the feed port in the pipe of the pile driver; connect it to the air compressor through a pipe, and take sealing measures.

[0052] S102: After the pile driver is assembled, carry out construction; pour sand into the pipe with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com