Machine room buffer compartment dedusting device

A technology for dust removal devices and compartments, which is applied to household cleaning devices, clothes hangers, special buildings, etc., can solve problems such as delay in maintenance time and pollution, and achieve the effect of preventing electrostatic adsorption of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

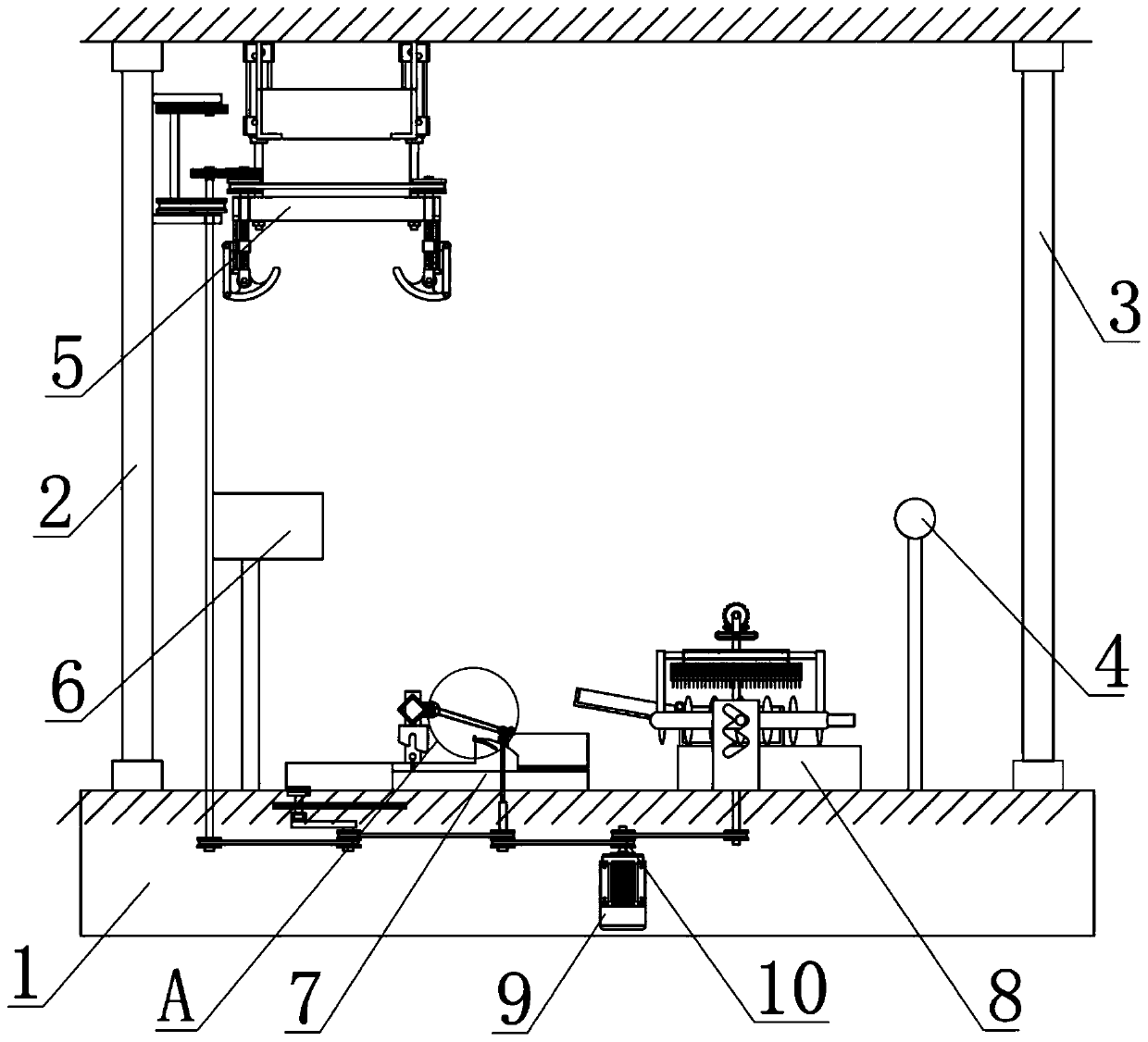

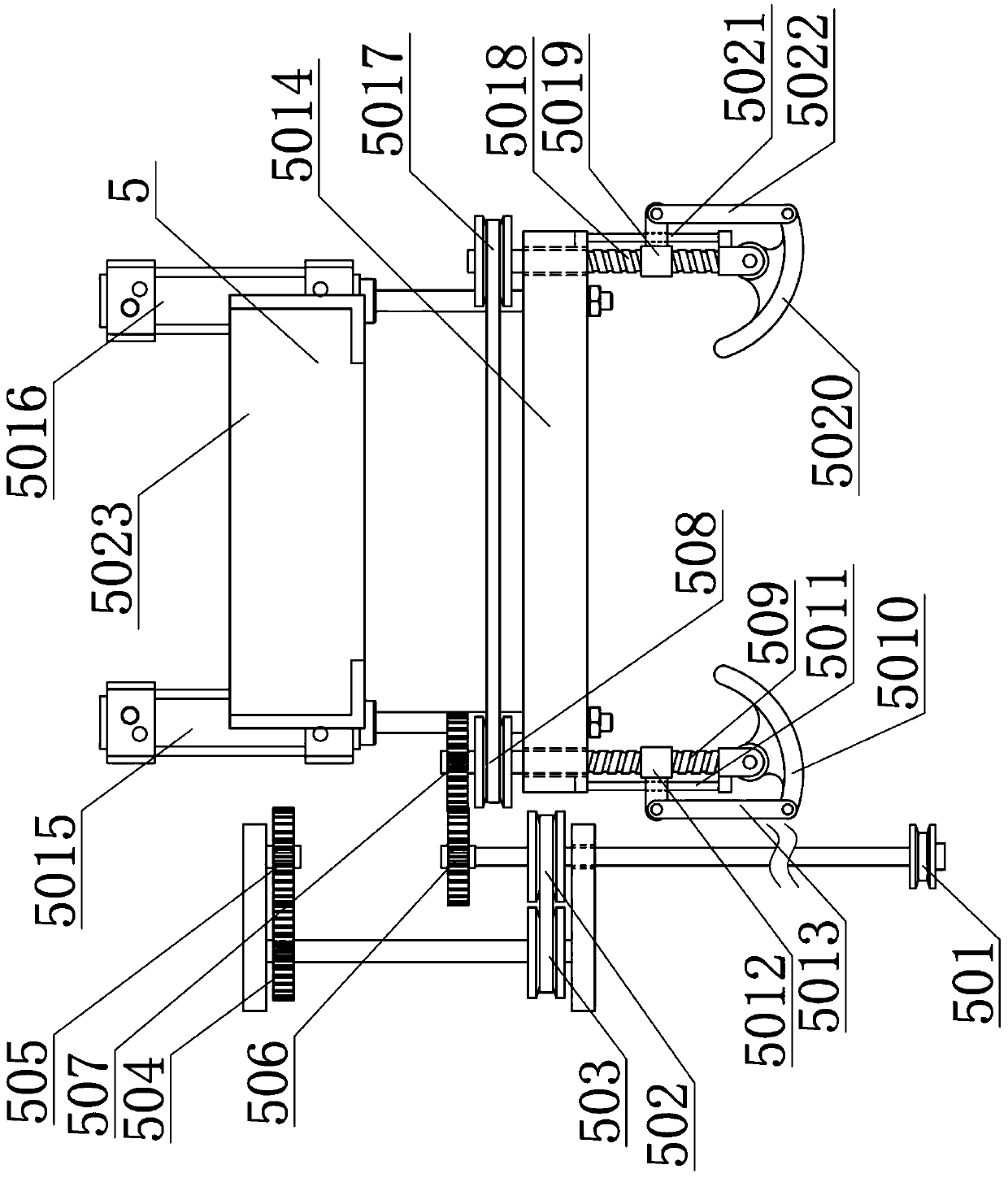

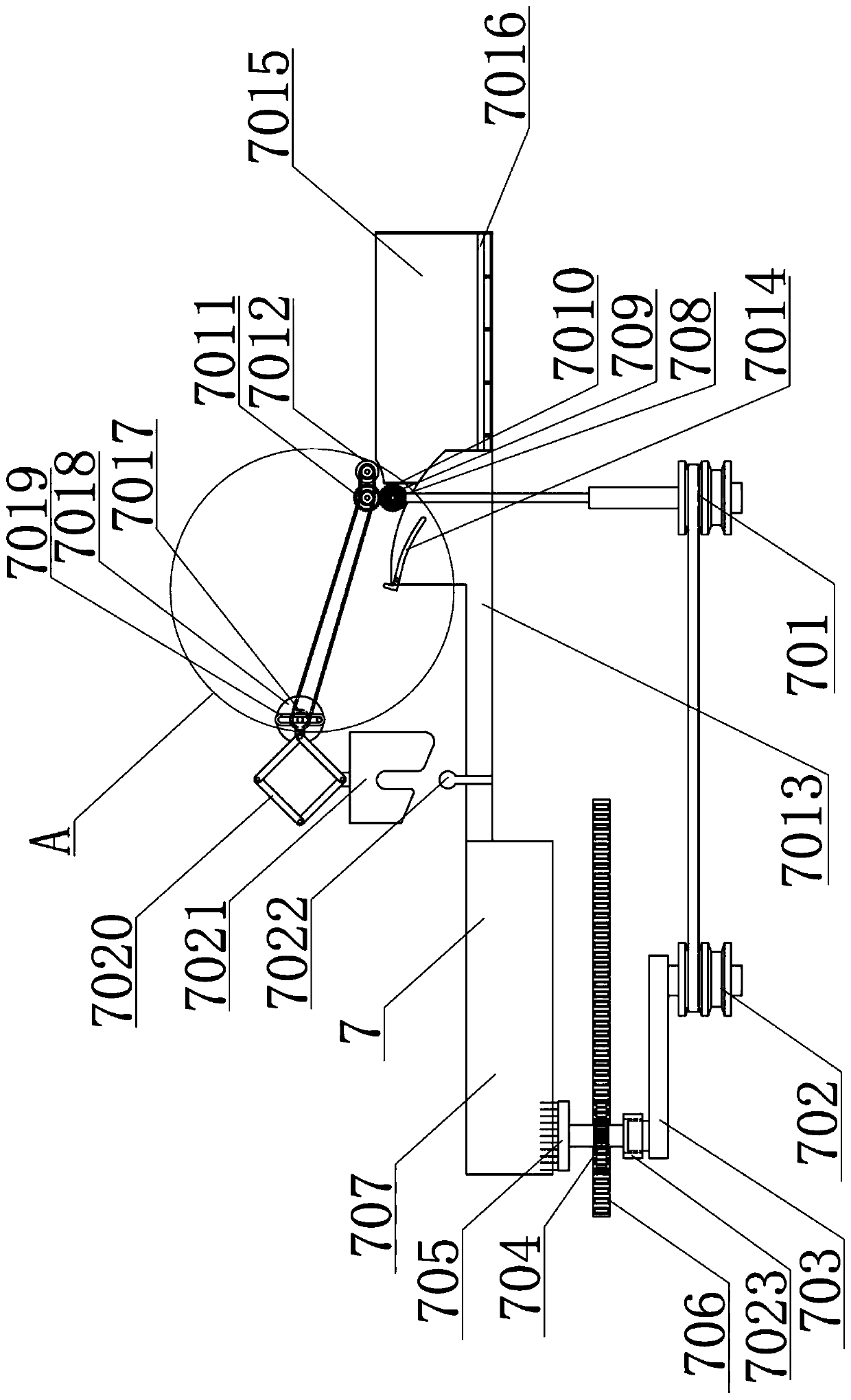

[0026] A kind of equipment room buffer compartment dedusting device, such as Figure 1-6 As shown, it includes the bottom installation cabin 1, the first isolation electric door 2, the second isolation electric door 3, the grounding electrostatic ball 4, the dust-proof electrostatic cap wearing mechanism 5, the control display 6, the foot soil cleaning mechanism 7, maintenance Box solution electrostatic mechanism 8, stepping motor 9 and first transmission wheel 10; the top left part of the bottom installation cabin 1 is slidingly connected with the first isolation electric door 2; the top right part of the bottom installation cabin 1 is connected with the second isolation electric door 3 for sliding connection; the top right part of the bottom installation cabin 1 is bolted to the grounding electrostatic ball 4; the top left part of the bottom installation cabin 1 is provided with a dust-proof electrostatic cap wearing mechanism 5; the top left part of the bottom installation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com