Dust-proof electric hoist for clean room

An electric hoist and clean room technology, applied in portable lifting devices, hoisting devices, etc., can solve problems such as wheel rust, poor paint adhesion, and inability to meet the requirements, and achieves prevention of electrostatic adsorption, high dustproof level, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

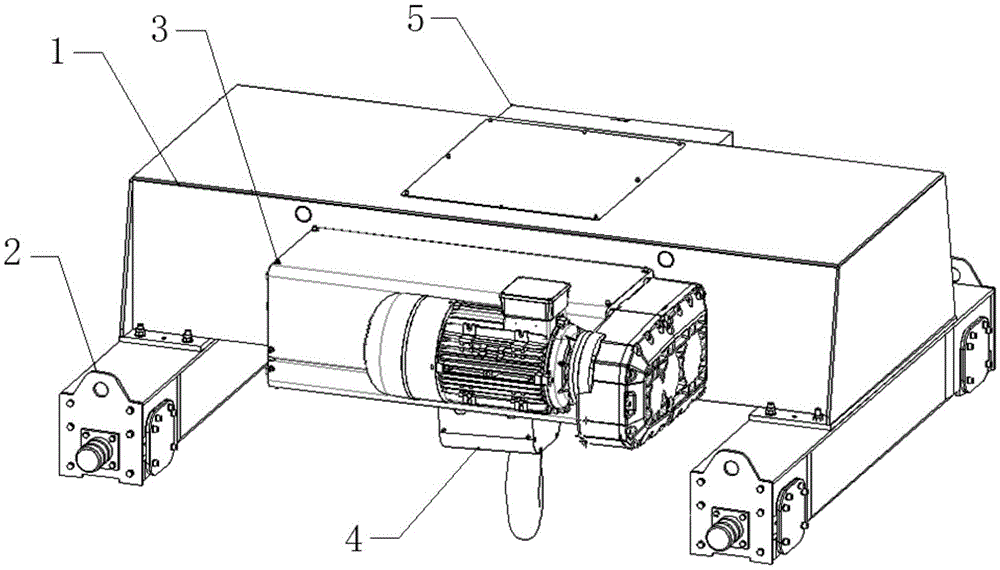

[0017] Example: refer to the figure 1 As shown, a dust-proof electric hoist for a clean room, including a steel structure main beam 1 , with steel structure girders 1 connected running device 2 , fixed to the main beam of the steel structure 1 lifting device on 3 , with lifting device 3 Attached hook device 4 , a fiber rope (not shown in the figure) used to lift heavy objects, and used to control the operation of the electric hoist and fixed to the main beam of the steel structure 1 electronic control device on 5 , characterized in that the operating device 2 , lifting device 3 , hook device 4 and electronic controls 5 They are respectively arranged in four closed shells, and at the same time, they are installed in the steel structure main girder 1 There is a layer of inorganic anti-corrosion coating (not shown in the figure) embedded with anti-static powder on the outer surface of the closed shell; anti-static powder refers to adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com