Shield body grouting structure and construction method for shield excavation in water-rich sand and pebble strata

A shield body grouting and construction method technology, which is applied in the direction of earthwork drilling, underground chambers, shaft equipment, etc., can solve the problems of shield tail settlement deformation, water seepage, and cement grouting body is easily diluted by water-rich strata, etc., to achieve The effect of reducing usage, reducing penetration, and preventing sudden settlement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

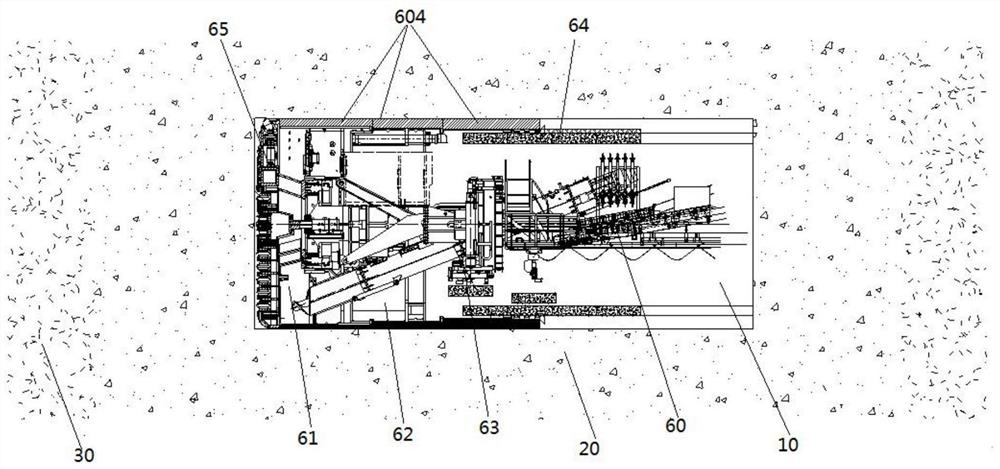

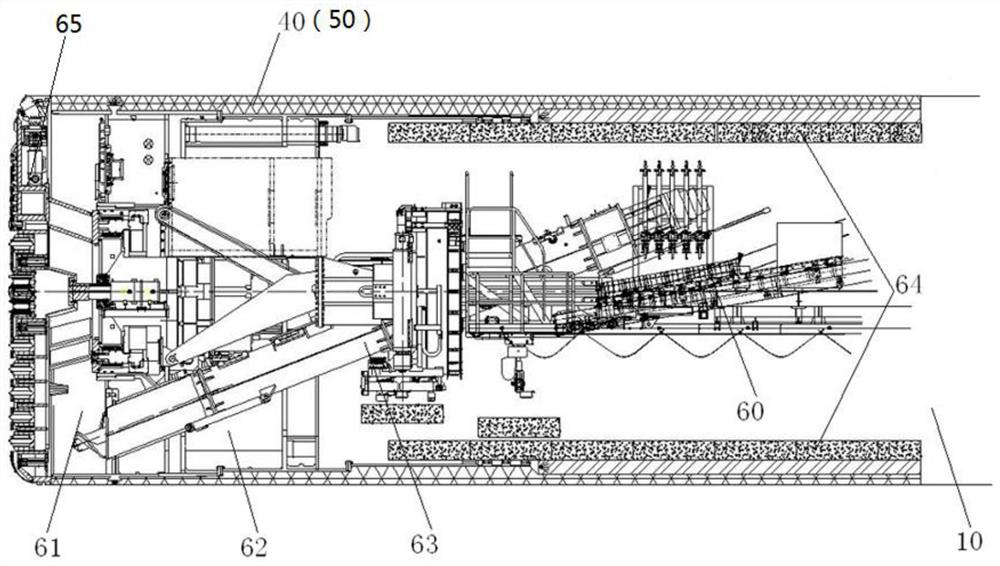

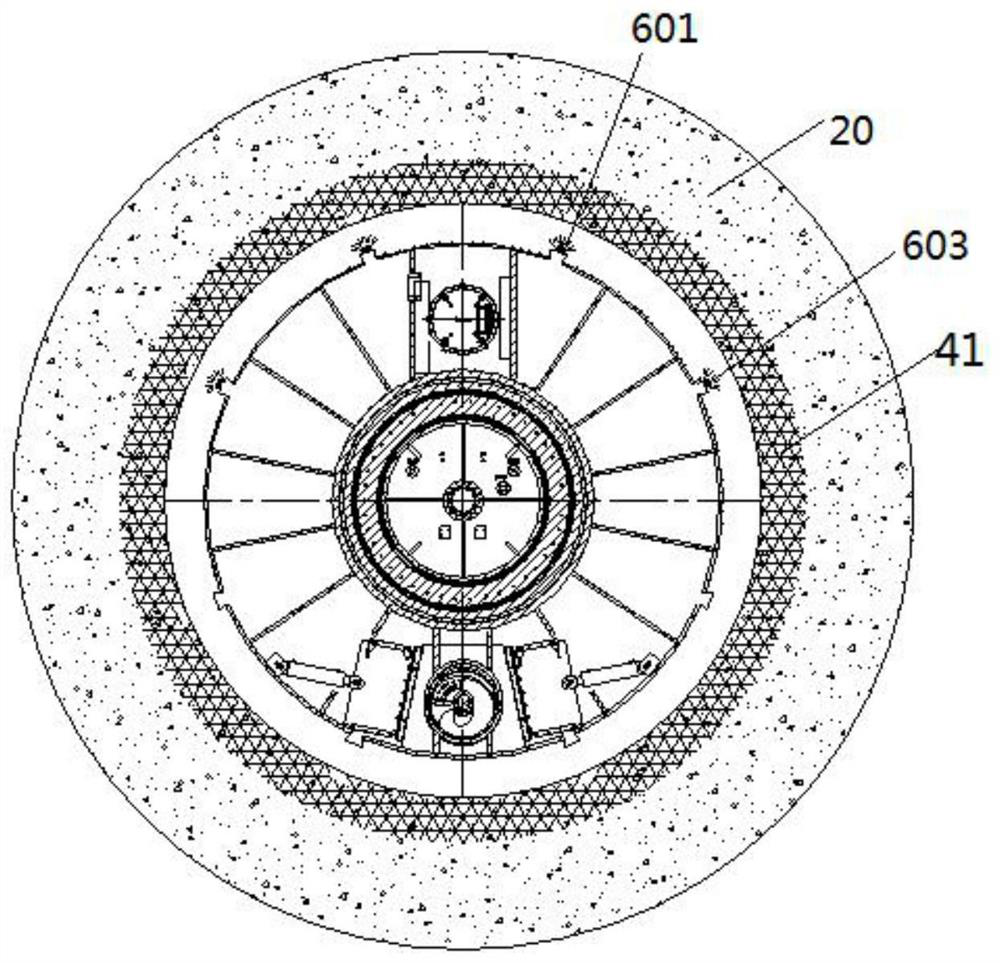

[0030] refer to figure 2 , a preferred embodiment of the present invention provides a shield body grouting structure for shield excavation in water-rich sand and pebble formations, including: a shield excavation channel 10 arranged along the extension direction of the tunnel or pipe gallery, and the shield excavation channel 10 It is arranged in the water-rich sand and pebble formation, and extends from the water-rich sand and pebble formation to adjacent formations connected with the water-rich sand and pebble formation. Injection molding in shield excavation channel 10 has first grouting double-circle 40 and second grouting double-circle 50 with the same structure but different injection molding methods, first grouting double-circle 40 and second grouting doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com