Clean indoor pollution source pollution gas rapid removal system

A technology to remove systems and pollution sources, applied in air-conditioning systems, heating methods, lighting and heating equipment, etc., can solve the problems of increasing FFU energy consumption, increasing the number of air returns of air-conditioning systems, and inability to quickly remove polluted air, so as to avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

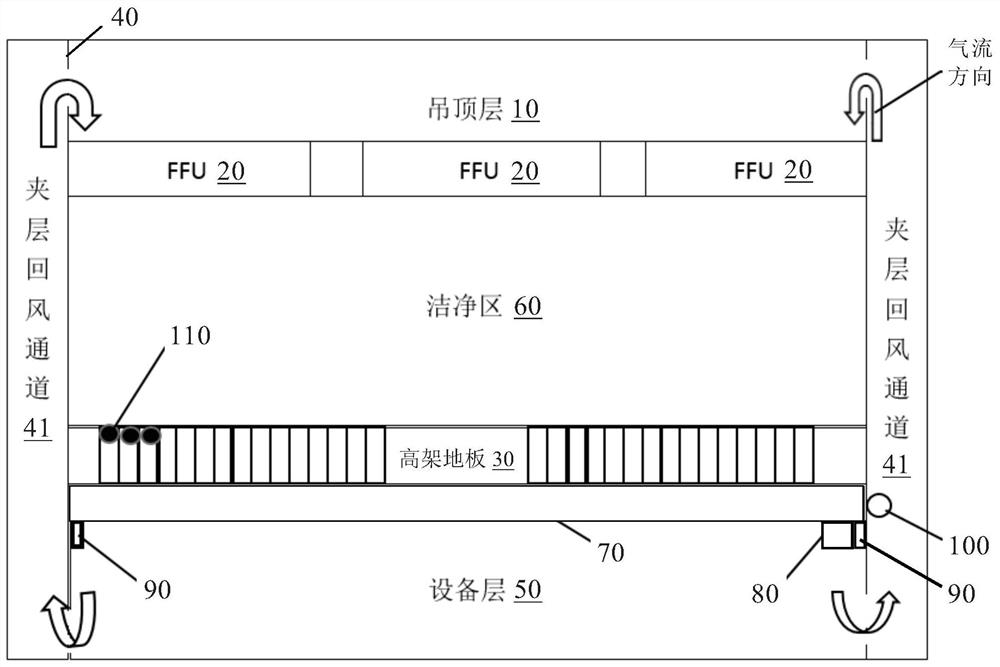

[0015] like figure 1 As shown, the rapid removal system of pollution source pollution gas in the clean room of the present invention is used for the removal of pollution gas discharged from fixed or mobile pollution sources in the clean room. The clean room includes a load-bearing wall 40 and an elevated floor 30. The load-bearing wall 40 is provided with a mezzanine return air passage 41. The equipment floor 50 is located below the elevated floor 30. The clean area 60 is above the elevated floor 30. The suspended ceiling is above the clean area 60. Layer 10, a plurality of FFU (fan filter unit with self-powered) 20 are installed below the suspended ceiling layer 10 . In the present invention, the composition of the clean room is an existing technology in this field, so it will not be described in detail, and the raised floor 30 and FFU 20 are existing decorative components or equipment in this field.

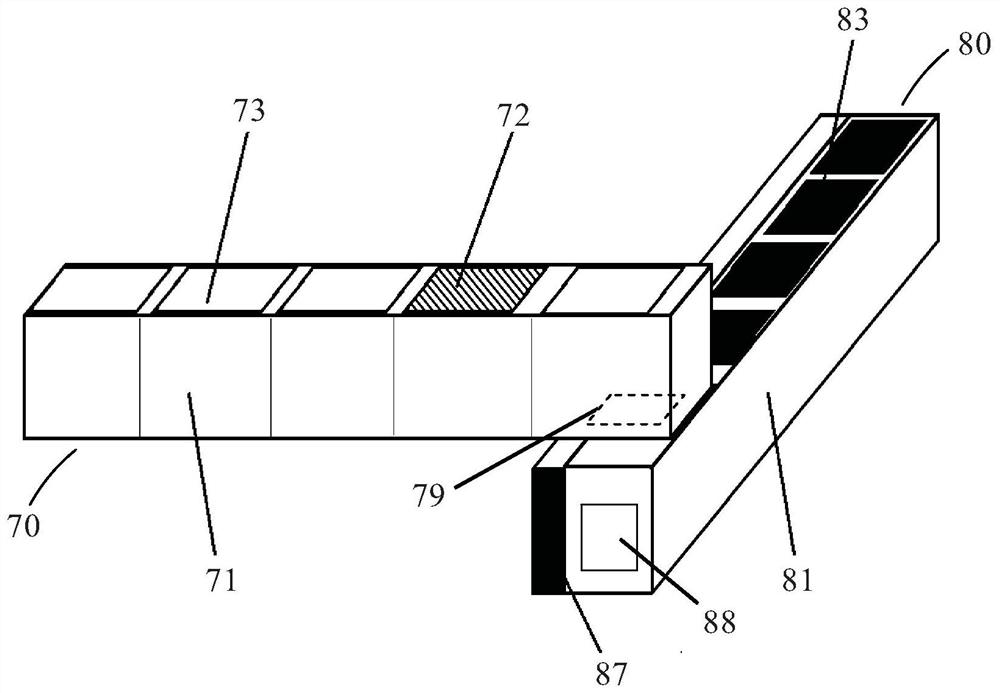

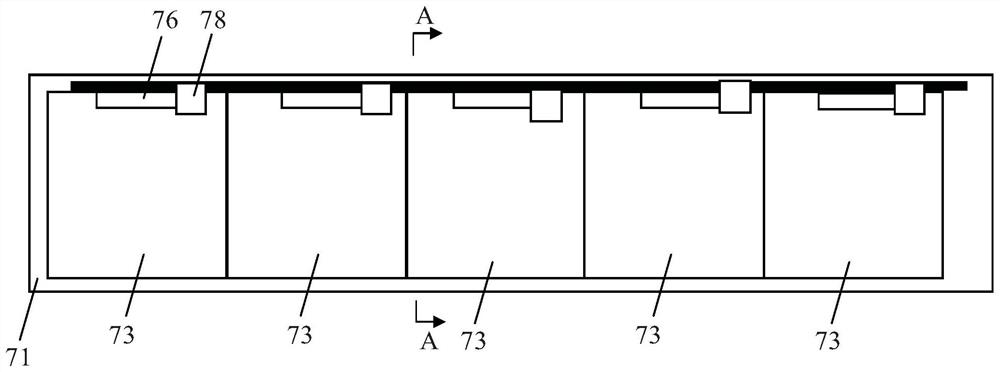

[0016] like Figure 1 to Figure 7 As shown, the system for quickly remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com