An active diversion grain auxiliary dehydration agricultural machinery

A technology for agricultural machinery and grain, applied in the field of active diversion grain-assisted dehydration agricultural machinery, can solve the problems of not being able to see the color of the grain with the naked eye, low work efficiency, troublesome process, etc. The effect of transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

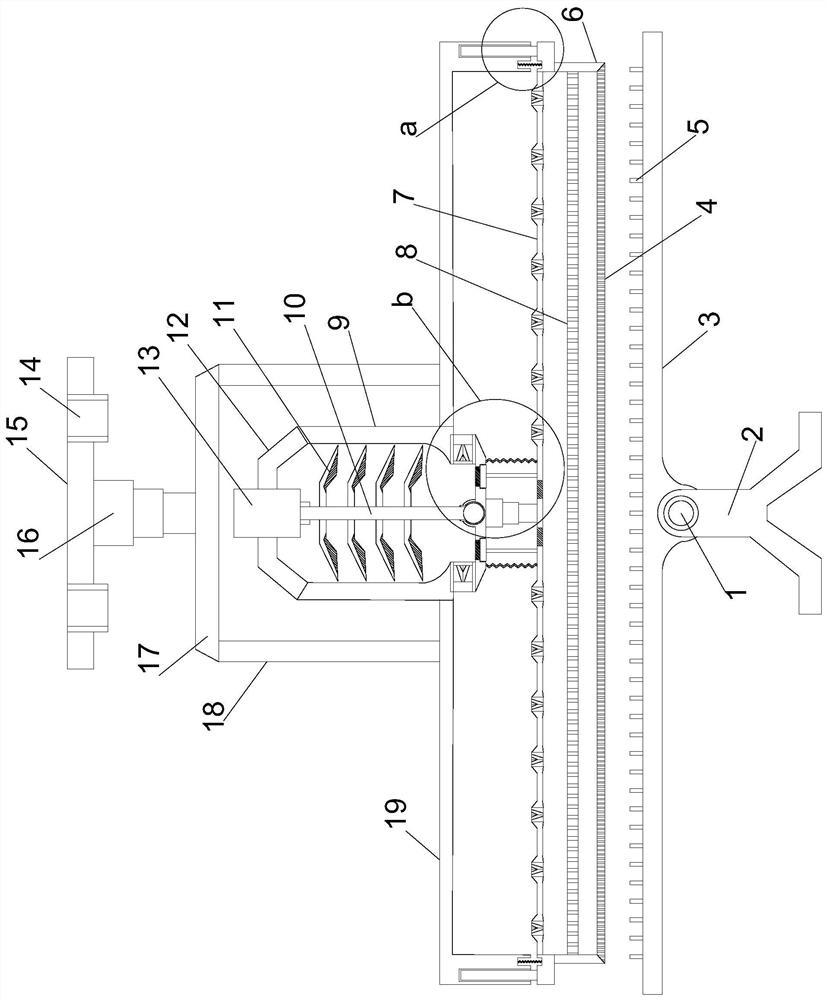

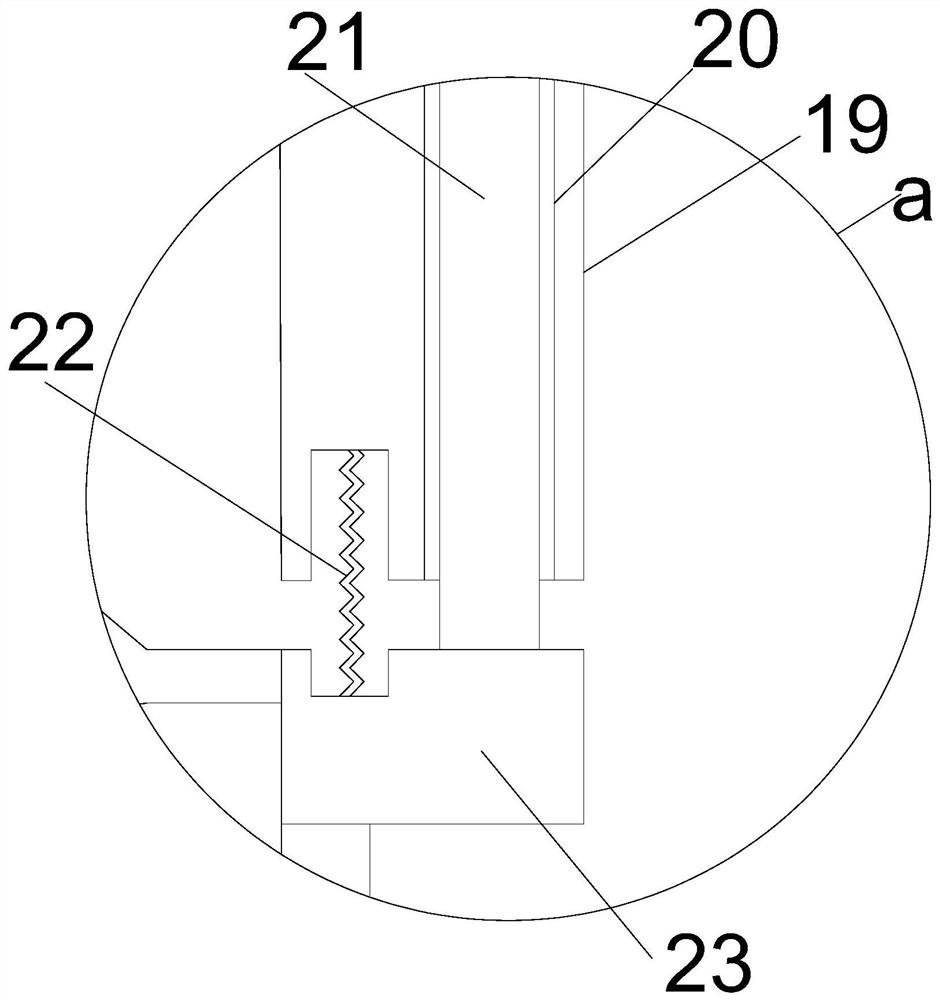

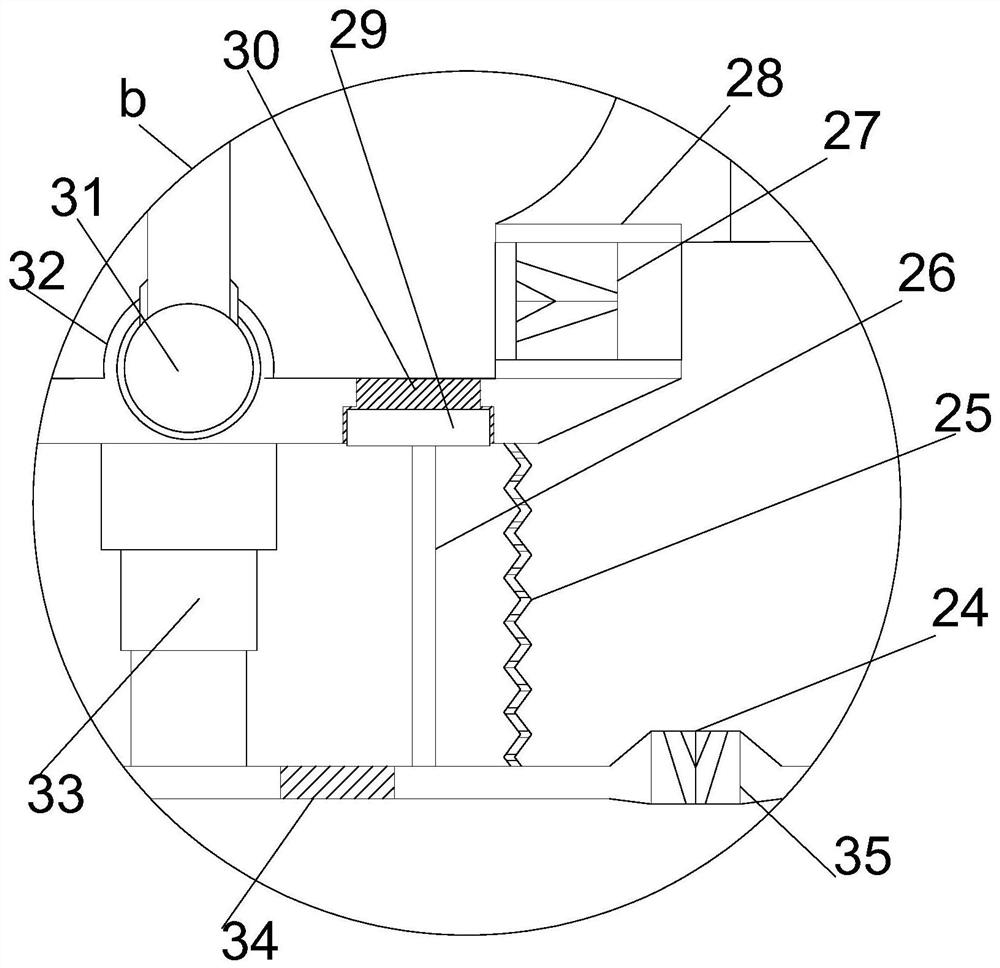

[0023] see Figure 1~4 , in an embodiment of the present invention, an active diversion type grain-assisted dehydration agricultural machine includes a support installation plate 15 arranged horizontally, a lifting transmission plate 17 is horizontally arranged directly below the support installation plate 15, and a lifting transmission plate 17 is arranged directly below the lifting transmission plate 17 The lifting installation cover 19 is arranged horizontally, and the edge of the lifting transmission plate 17 is equiangularly provided with some supporting installation columns 18 downwards. An electric control lifting column 16 is arranged vertically downward, the lower end of the electronic control lifting column 16 is fixed on the upper end of the lifting transmission plate 17, and the support mounting plate 15 is provided with a number of fixed mounting holes 14 at equal angles with the electric control lifting column 16, and the lifting installation cover The middle pos...

Embodiment 2

[0026] On the basis of Embodiment 1, through the cooperation of the positioning guide column 21 and the positioning guide groove, the lifting and telescopic displacement is continuously stable, and the telescopic guide tube 25 and the elastic guide tube 22 make the forward and reverse guide space of the device It can be divided quickly and can adapt to the diversion during the change process. The limit guide column 5 can realize the good air circulation effect during the drying and dehydration process of the grain. By electronically controlling the rotating shaft 1, the swing mounting plate 3 Angle, to achieve fast material guide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com