A parallel loop mixed water heat exchange pid control system and its control method

A control system and parallel technology, applied in heat exchange equipment, lighting and heating equipment, instruments, etc., can solve the problems of long fitting time, many adjustment rounds, mutual interference of control valves, etc., and achieve high adjustment accuracy and short adjustment time. , Adjust the effect of less rounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

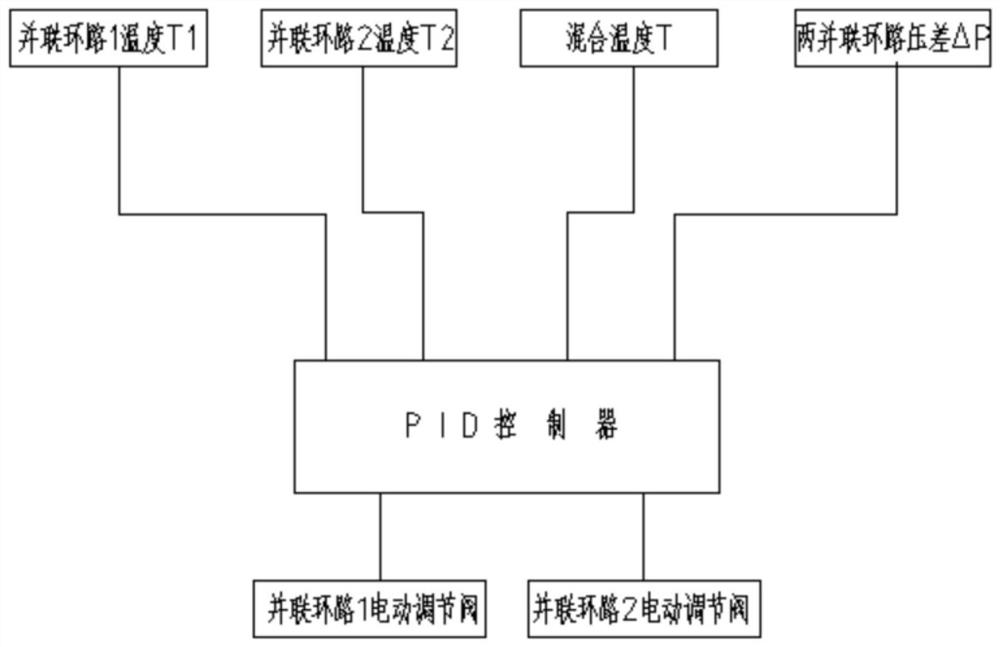

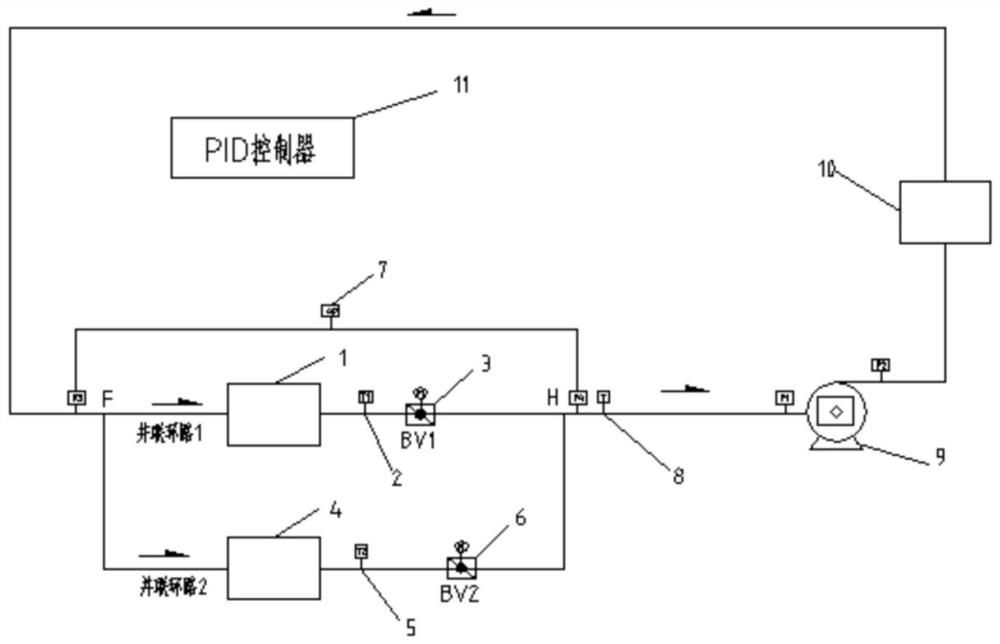

[0029] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure I-2As shown, a parallel loop mixed water heat exchange PID control system includes a PID controller connected through a signal line, a temperature acquisition module, a pressure difference acquisition module, and an electric regulating valve control module. The entire water circuit in the closed circulation system includes One main line and two parallel branch lines form parallel water mixing parallel loop Ⅰ and parallel loop Ⅱ. The two parallel branch lines are equipped with separate cooling or heating equipment, temperature sensors and electric regulating valves, of which the parallel loop Road I requires an energy loop for heat exchange with mixed water, and parallel loop II provides an energy loop for heat exchange with mixed water. The water main line is equipped with a mixed water temperature sensor 8, a circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com