Vernier caliper data automatic acquisition system and method

A vernier caliper and automatic acquisition technology, applied in transmission systems, sliding gauges, electrical components, etc., can solve problems such as low efficiency, lack of real-time performance, reduced data accuracy and reliability, and achieve fast acquisition process, safe and reliable transmission, Eliminate the effect of filling in data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

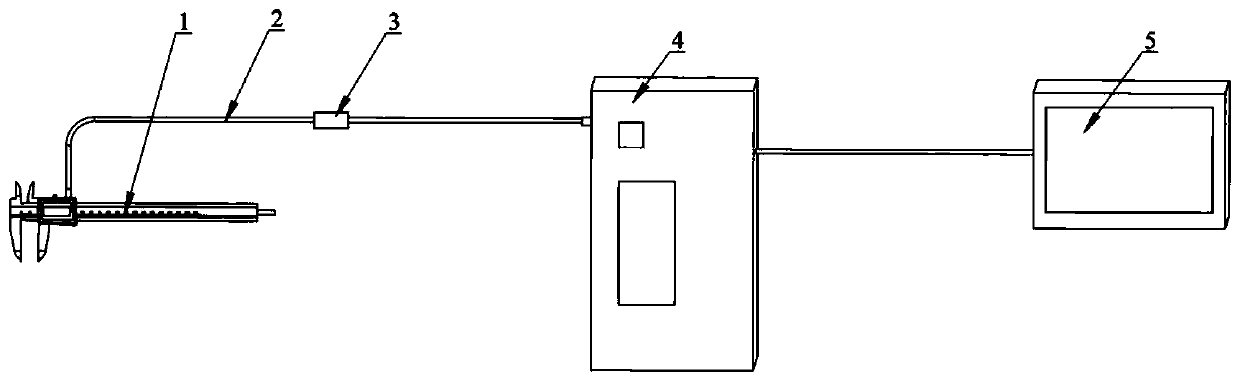

[0037] First, connect one end of the transmission line 2 to the data output interface of the digital display vernier caliper 1, and the other end to the server 4, such as figure 1 As shown, then open the driver software, log in to the account, and then use the digital display vernier caliper 1 to clamp the test piece. One of the hands holds one end of the digital display vernier caliper 1, pushes the push roller on the digital display vernier caliper 1, and the other hand Place the tested piece between the measuring claws, turn the limit screw above the digital display vernier caliper 1, adjust until the measuring claw on the digital display vernier caliper 1 clamps the tested piece, then observe the data displayed on the display screen, and wait for the data to display After stabilization, press the confirmation button 3 on the transmission line 2, the data is directly collected into the server 4, and then the calculation module in the driving software automatically calculates...

Embodiment 2

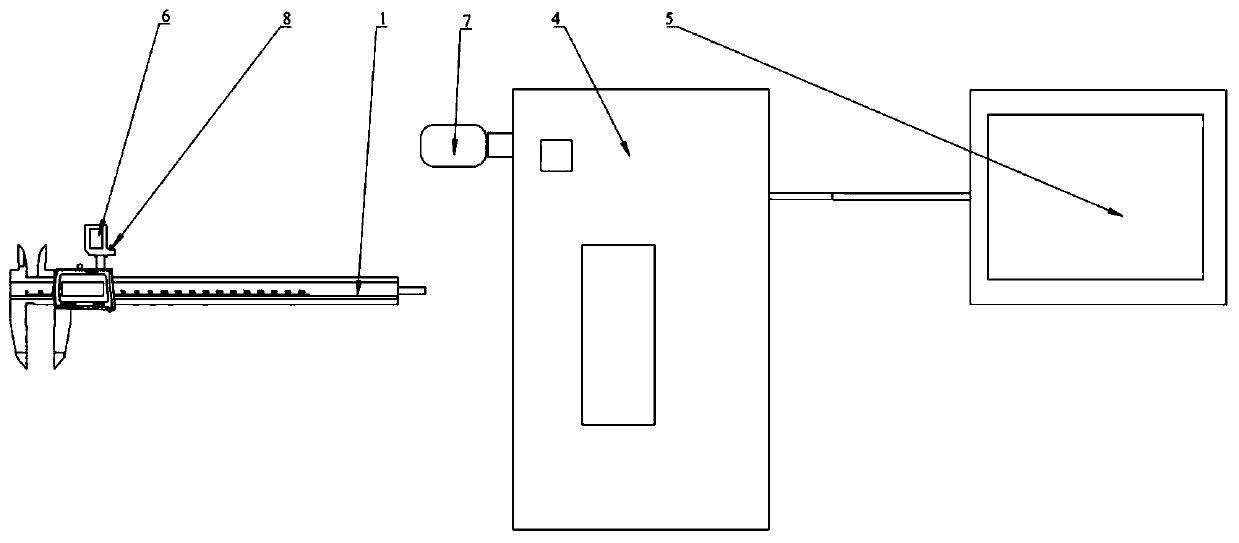

[0040] First install the signal transmitter 6 at the data output port of the digital display vernier caliper, connect the receiver 7 to the server, and connect the server and the display, such as figure 2 As shown, then open the driver software, log in to the account, and then use the digital display vernier caliper 1 to clamp the test piece. After the displayed value is stable, press the data collection button 8 on the signal transmitter 6, and the signal transmitter 6 will collect the collected data. The signal is sent out, the receiver 7 receives the data signal, and transmits the data signal to the server, then the driving software collects the measurement data, and automatically calculates the median value, After the calculation of the result of the average value is completed, a preview form is generated, displayed on the display 5, and the result data is saved in the data storage module.

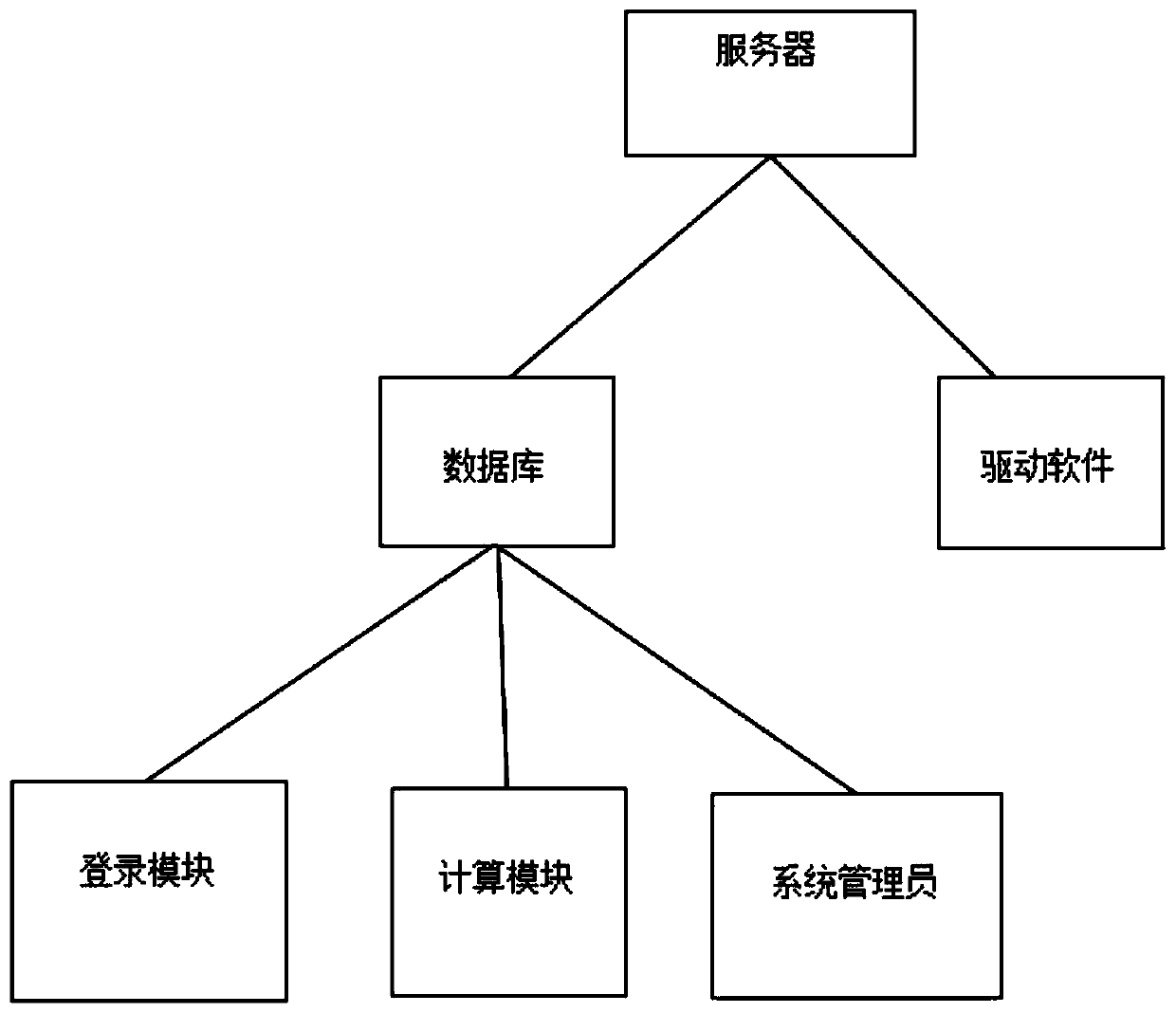

[0041] In the present invention, a system administrator can be set inside the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com