Method for testing shock resistance of multi-layer co-extrusion film infusion soft bag

A technology of impact resistance and infusion soft bags, which is applied in the direction of testing material strength by using one-time impact force, testing material strength by applying repeated force/pulsation force, and measuring devices, which can solve problems such as liquid leakage and unusable medicines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for testing the impact resistance of a multi-layer co-extruded film transfusion soft bag, which comprises the following steps:

[0032] Step 1: Use the filling equipment to prepare samples of infusion bags, and randomly select N samples of infusion bags for testing;

[0033] Step 2: Place N samples of infusion bags at -25°C±2°C for T1 hour; then at 50°C±2°C for T2 hours; then at 23°C±2°C for T2 hours T3 hours;

[0034] Step 3: Set the required test conditions. Under the set test conditions, the above-mentioned infusion bag sample is subjected to an impact test using an impact tester. The infusion bag sample should be placed horizontally, the impact surface should be horizontal, and the impact area should be Not less than 50mL or 100mL or 125mL or 250mL or 1000mL single-sided full contact area, and record the impact results;

[0035] Step 4: Calculate the impact resistance value and impact leakage rate by the formula:

[0036] The formula is:

[0037] λ=∑n ...

Embodiment 2

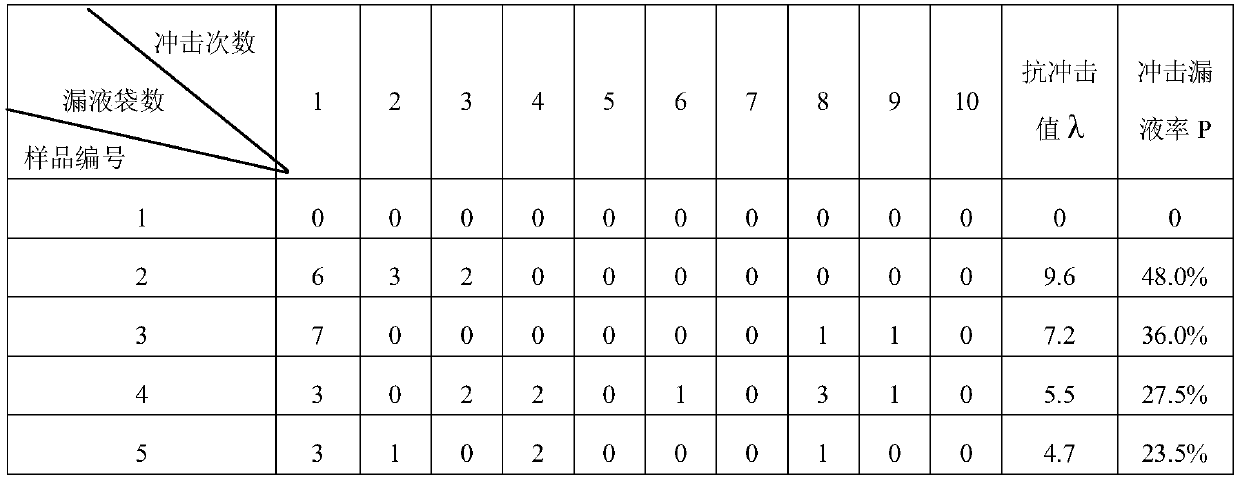

[0053] Utilize the multi-layer co-extrusion film transfusion soft bag impact resistance performance test method among the present invention to carry out the test of impact resistance performance to the five-layer film of different samples, filling equipment selects same filling production line, the test result of sample is shown in Table 1 .

[0054] Table 1 The impact resistance test results of different samples

[0055]

[0056] Through the method of the present invention, the pit impact performance of each sample can be tested, and the impact resistance value λ of each sample can be calculated, and the results are shown in Table 1. Combining this method with Table 1, it is not difficult to find that sample 1 has the lowest impact resistance value, the best impact resistance performance, and is least prone to liquid leakage; sample 2 has the largest impact resistance value, and its impact resistance performance is relatively the worst. Leaks easily. Through the comparis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com