Velocity field and density field synchronous measurement system and method

A technology of synchronous measurement and density field, applied in velocity/acceleration/impact measurement, fluid velocity measurement, full-field flow measurement, etc., can solve the problems that cannot reflect the influence of temperature distribution in the heat transfer process, limit the application of NPLS technology, and achieve synchronization Accurate measurement results, improved acquisition frequency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

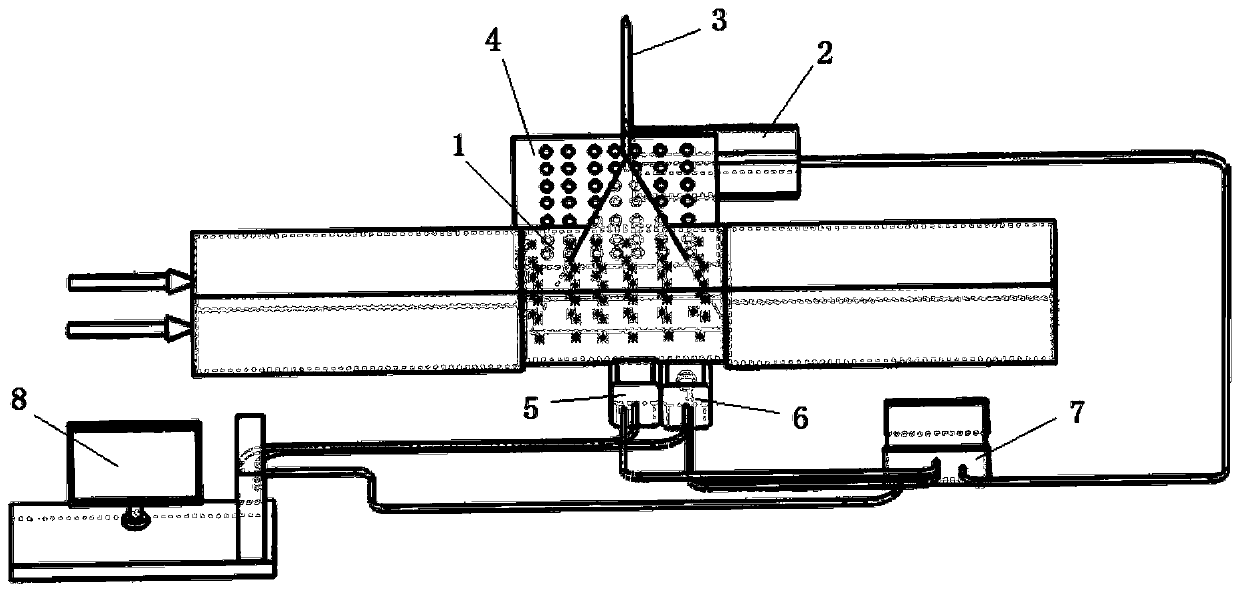

[0067] The laser 2 in this embodiment is a Nd:YAG dual-cavity laser with a pulse frequency of 15 Hz, a laser wavelength of 550 nm, a pulse energy of 120 MJ, and a pulse width of 10-12 ns. The laser light source emitted by the laser 2 is adjusted to be a sheet light source, the thickness of the sheet light is 1mm, and the flow field is irradiated vertically.

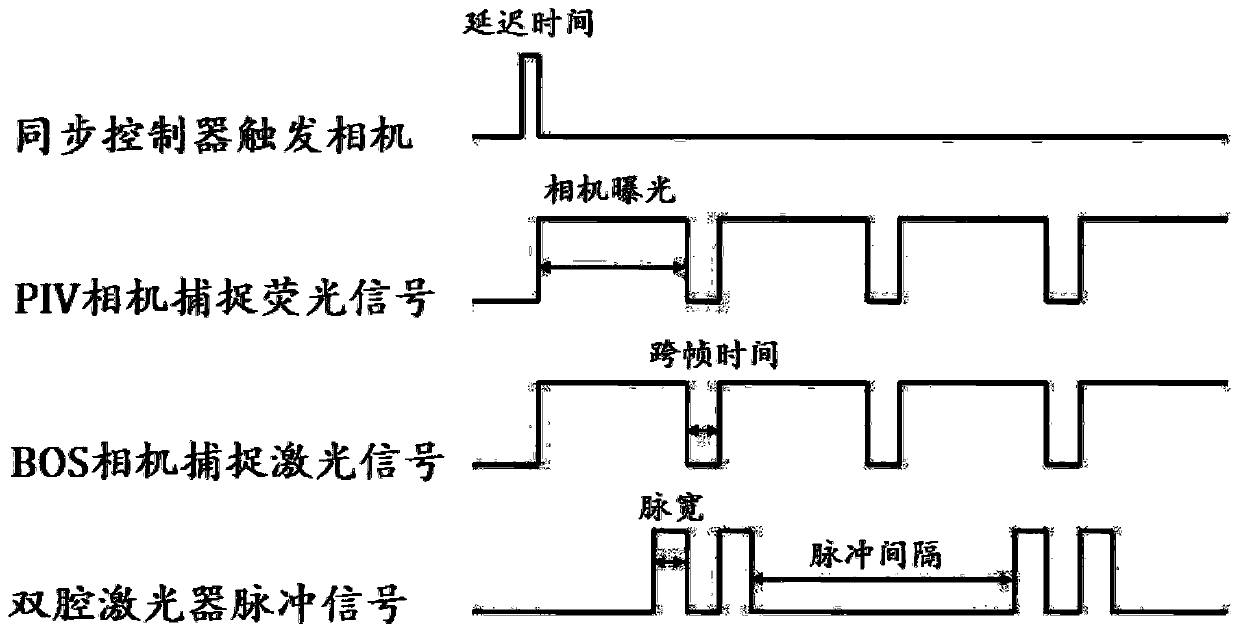

[0068] The first CCD camera 5 and the second CCD camera 6 are both high-speed frame-crossing CCD cameras. The shortest frame-crossing time of the two high-speed frame-crossing CCD cameras is 0.5μs, and the acquisition frequency can reach 1280×800pixels when the camera resolution is guaranteed 1630Hz. BOS camera (the second CCD camera 6) is equipped with a narrow-band filter with a wavelength of 550nm±5nm in front of the lens to only capture the laser signal, while the lens of the PIV camera (the first CCD camera 5) is equipped with a single-pass filter with a wavelength of 580nm Only fluorescent signals are captured. Th...

specific Embodiment approach 2

[0073] This embodiment provides a supercritical CO 2 Simultaneous measurement system of velocity field and density field in flow heat transfer process.

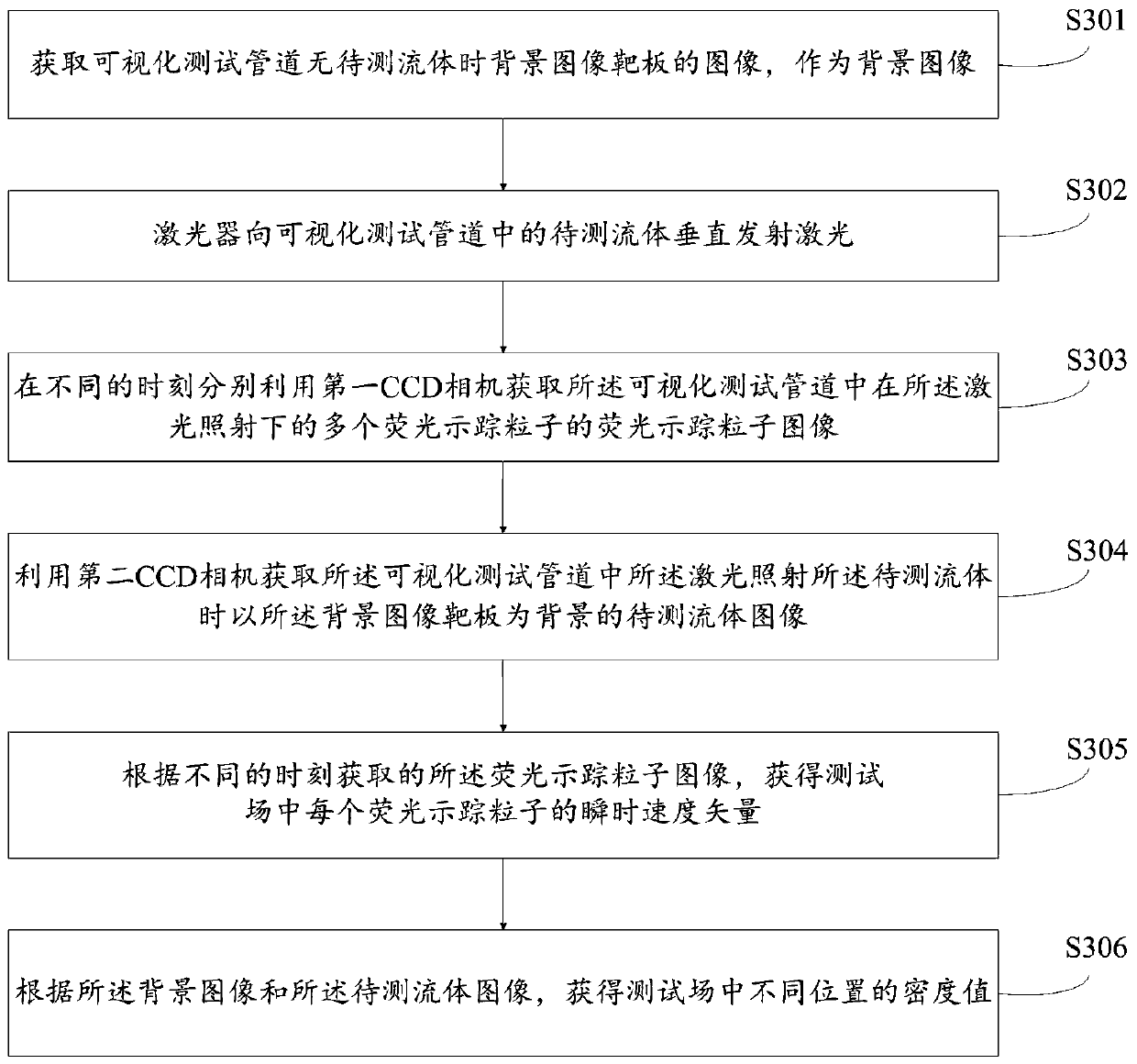

[0074] Supercritical CO 2 Flow through a rectangular stainless steel pipe with a size of 10mm*10mm*600mm, apply a certain amount of heat on the outer wall, and connect a visual test section with a pipe length of 100mm at the outlet, and the mass flow rate of the working fluid is 600kg / (m 2 ·s), the temperature range is 35-50°C, and the pressure is 8MPa. The specific settings are as follows:

[0075] 1. Determine the position of the test section, camera, background image, and laser lighting; take the location of the test section as a reference, adjust the laser beam to pass through the center of the test section vertically; place the PIV and BOS cameras side by side, facing the experimental measurement section , the background image is facing the BOS camera with the test section as the center, and the two cameras and the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com