A high-sensitivity solenoid valve constant current drive control method

A constant current drive, solenoid valve technology, applied in the control/regulation system, valve details, valve device and other directions, can solve the problems of weak dynamic adjustment ability, low control accuracy, large reverse voltage, etc., to achieve dynamic adjustment ability Strong, increase the transmission efficiency, the effect of small output ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

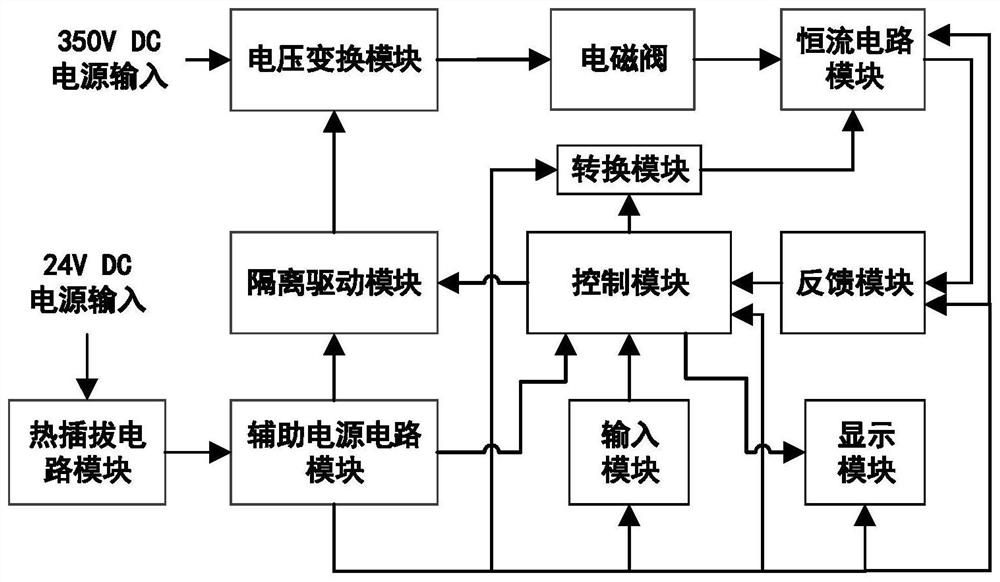

[0051] For the convenience of understanding the method of the present invention, with figure 1 Taking the solenoid valve drive circuit as an example, the structure and working principle of the solenoid valve drive circuit are described, and a high-sensitivity solenoid valve constant current drive power supply is provided. The drive power supply specifically includes a voltage conversion module, an isolation drive module, and a control module. , conversion module, constant current circuit module, feedback module, input module, display module, hot-swappable circuit module and auxiliary power circuit module. The input module is specifically a button, which is used to set the expected value of the output current of the constant current circuit module and dynamically adjust the driving power. The conversion module is specifically a DA converter, which is used to convert the digital reference signal output by the control module into an analog reference signal. The display module is...

Embodiment 2

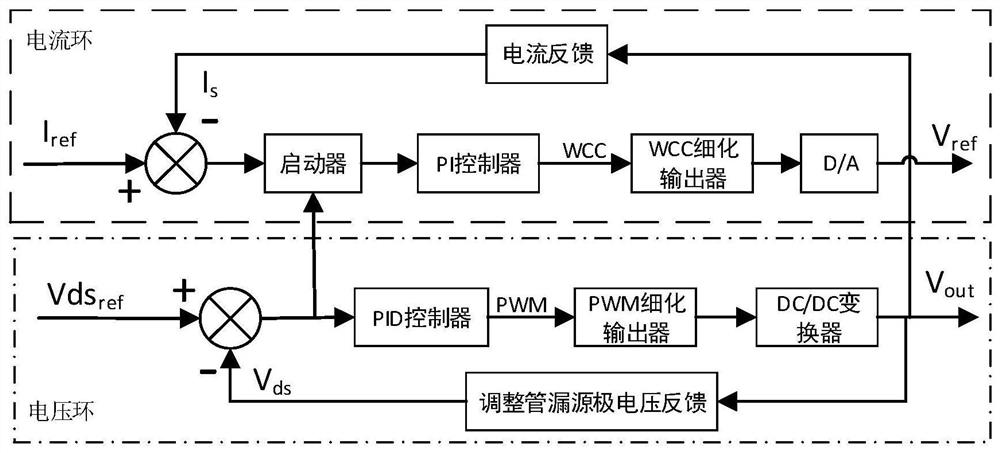

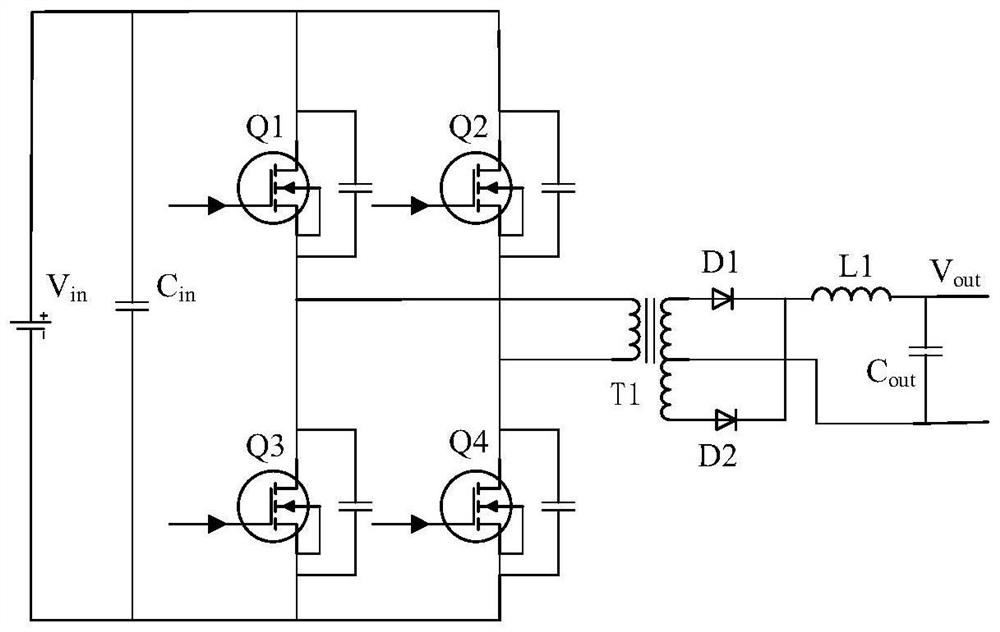

[0064] Such as Figure 5 As shown, the purpose of the present invention is to overcome the problems of large reverse voltage, weak dynamic adjustment ability, and low control precision of the existing solenoid valve drive circuit, and provide a high-sensitivity solenoid valve constant current drive control method. The valve constant current drive circuit parameter information refines the output current of the solenoid valve constant current drive circuit to avoid large reverse voltage, strong dynamic adjustment capability, and high control accuracy. Wherein, the circuit parameter information includes the feedback current, the drain-source voltage information of the regulator tube in the voltage loop inside the solenoid valve constant current drive circuit. More specifically, as Figure 6 As shown, the method of the present invention is implemented based on the voltage envelope current technology. In the figure, the mark 1 is the output voltage waveform of the electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com