Method and equipment for preparing solar cell string

A technology of solar cells and equipment, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of restricting production efficiency and long time consumption, and achieve the effects of saving transmission and moving time, reducing loss, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

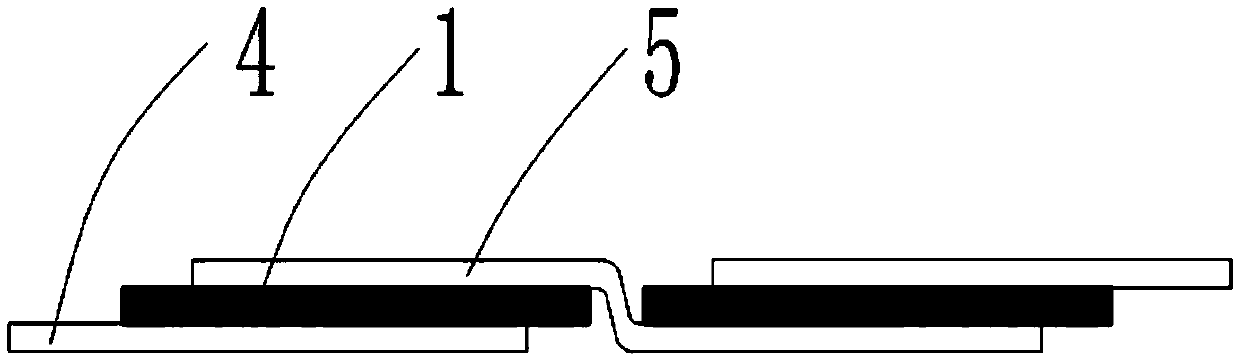

[0045] Such as figure 1 As shown, the solar cell string used in this embodiment contains two cells (1, 1'), and the two lengths are L 1 The first conductor strips 4 located below the first cell and above the end cell respectively, a set of length L 2 And connect the second conductor strip 5 of two battery slices (1, 1'), the two battery slices are separated by a distance of length S.

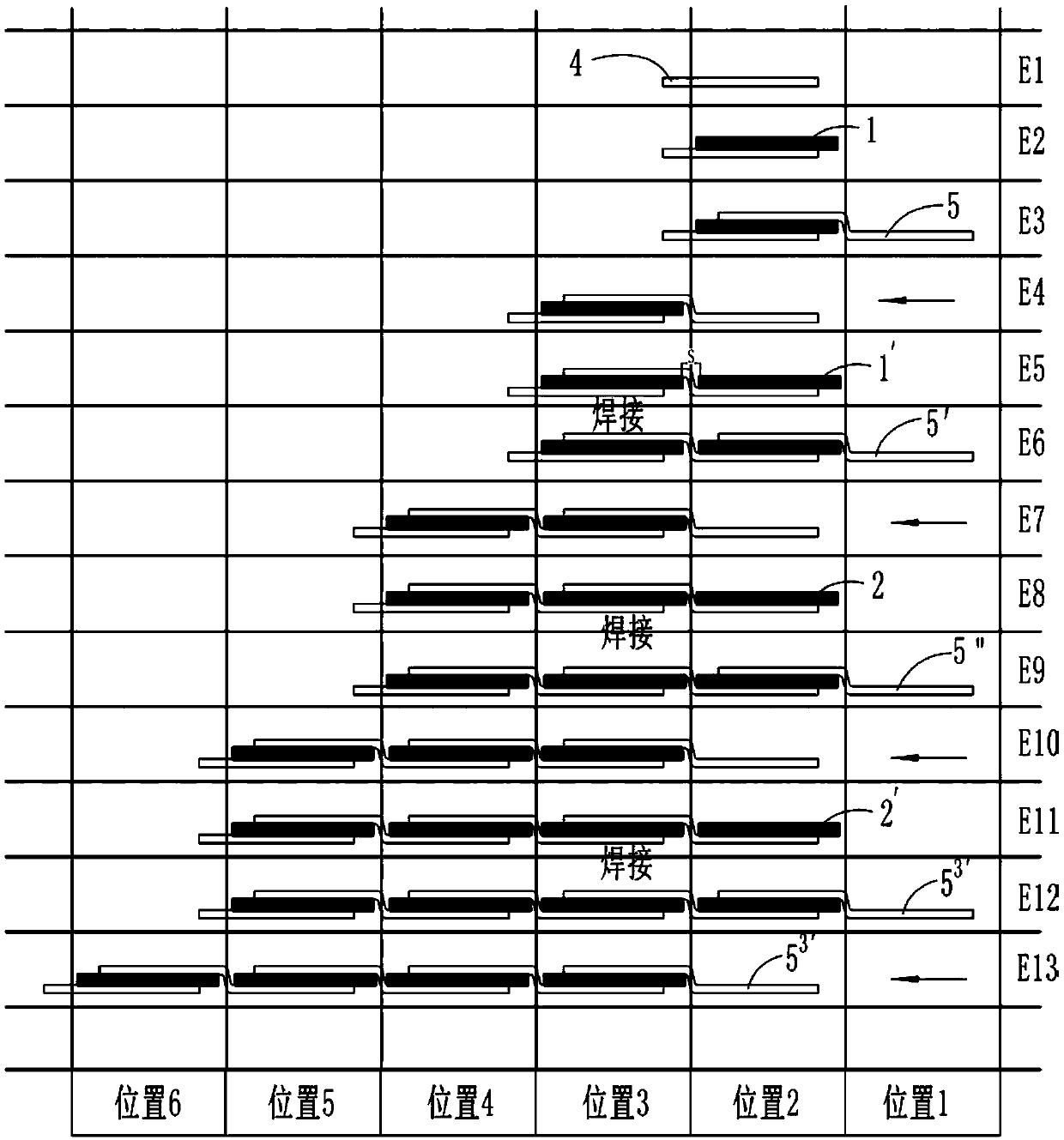

[0046] Such as Figure 5 with Image 6 As shown, a method for preparing a solar cell string, two cells (1, 1') and a group of second conductor strips 5 are placed, and the transport device carrying the cells moves forward for a distance of T, T= 2*(S+the length of a single cell), for the cells and conductor strips delivered to the welding station, the welding device completes the interconnection welding of two cells (1, 1') and a set of conductor strips 5 .

[0047] The specific implementation process is: place the first conductor strip 4, the first battery piece 1, the second conductor stri...

Embodiment 2

[0050] Such as Figure 7 with Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that, in the specific implementation process, before the transmission mobile device moves forward, the first conductor strip 4 is first placed on the second battery sheet 1', and the transmission mobile device moves forward. After the length is the distance of T, T=2*(S+length of a single battery sheet), the welding device performs mutual exchange of two battery sheets (1, 1'), two groups of first conductor strips 4 and one group of second conductor strips 5 Even welding. All the other are identical with embodiment one.

Embodiment 3

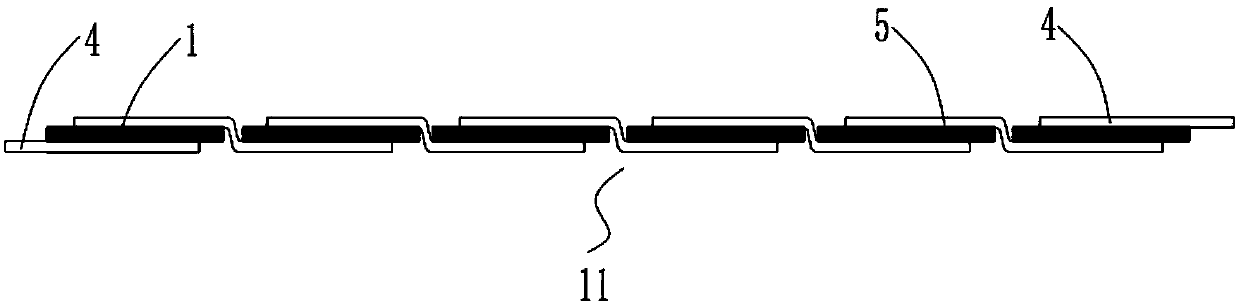

[0052] Such as figure 2 As shown, the solar cell string used in this embodiment contains 6 cells (1, 1', 2, 2', 3, 3'), and two sets of length L1 are respectively located under the first cell and the end cell The upper first conductor strip 4, 5 second conductor strips (5, 5', 5", 5 with a length of L2 and connecting 6 battery pieces (1, 1', 2, 2', 3, 3') 3 ', 5 4 '), two adjacent groups of cells are separated by an interval of length S.

[0053] Such as Figure 9 with Figure 10 As shown, a method for preparing a solar battery string provided by this embodiment is specifically: when placing two battery sheets (1, 1') and two sets of second conductor strips (5, 5'), the carrying battery The transmission and moving device of the sheet moves forward for a distance of T, T=2*(S+length of a single cell), and the welding device completes two cell sheets (1, 1 ') and the interconnection welding of two sets of conductor strips (5, 5').

[0054] In this embodiment, when the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com