A binary distillation tower temperature control system and method

A temperature control method and distillation column technology, which are applied in distillation regulation/control, separation method, distillation separation, etc., can solve the problem of limiting the effective application of temperature inference control systems, hindering the development of new distillation systems, and temperature inference control systems are difficult to give control. quality and other issues, to achieve the effect of reducing dynamic deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

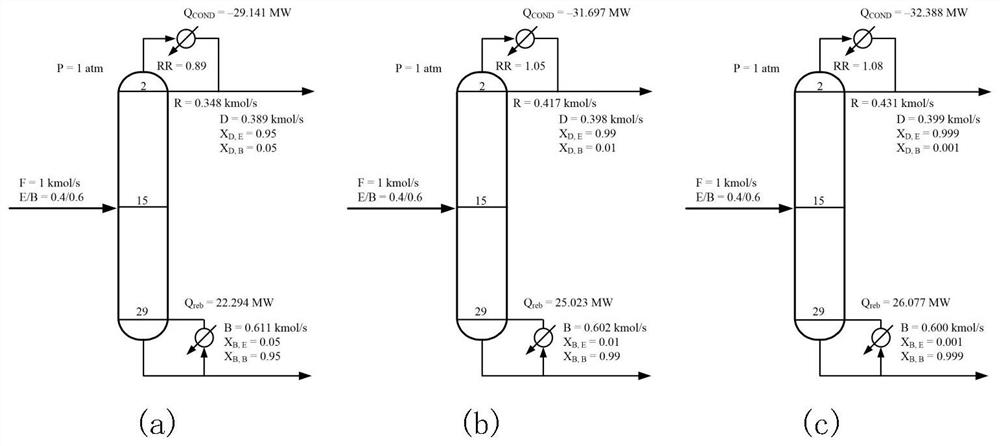

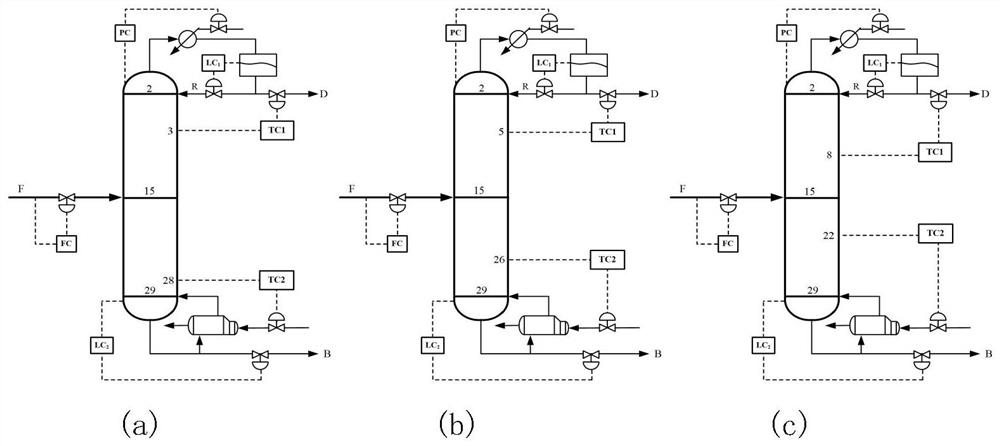

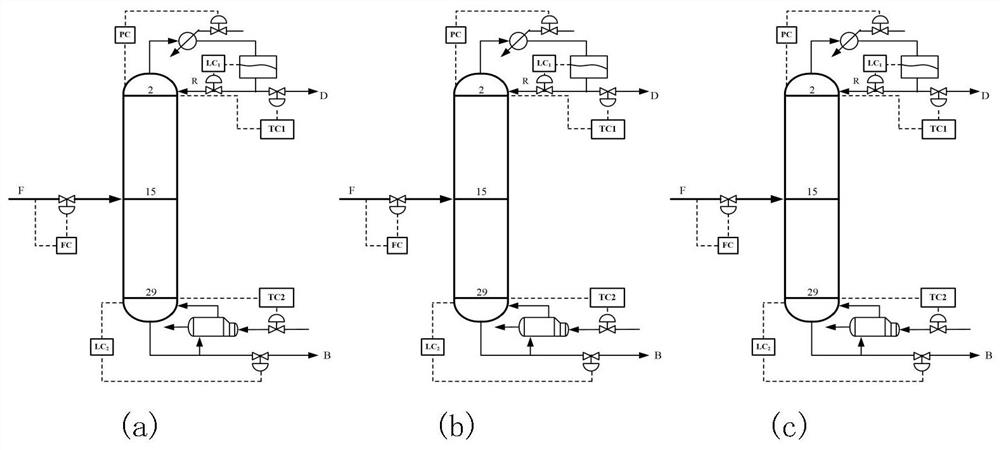

[0029] In order to make the purpose of the present invention, technical solutions and advantages clearer, the present invention takes the simple distillation column of separating ethanol (E) / butanol (B) binary mixture as an example, and has three kinds of product concentrations of low, medium and high The synthesis and design of its temperature inference control system are studied under steady-state operating conditions, and the invention is further described with reference to the accompanying drawings. figure 1 The steady-state structures of these three systems are given. The top product has the same purity as the bottom product, and its low, medium and high concentration specifications are 95% mol (Example I), 99% mol (Example II) and 99.9% mol (Example III) respectively.

[0030] Since the reflux ratios of these three distillation towers are all around 1.0, far less than 3.0, the output flow rate (D) at the top of the tower and the heat load of the reboiler (Q reb ) should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com