A method for setting the flattening amount of straightening rolls for super-large-diameter seamless steel pipes

A seamless steel pipe and super-large diameter technology, which is applied in the field of setting the flattening amount of the super-large diameter seamless steel pipe straightening roller, can solve problems such as unsatisfactory rounding effect, improve product straightening accuracy and reduce thread indentation , Improve the effect of ellipticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

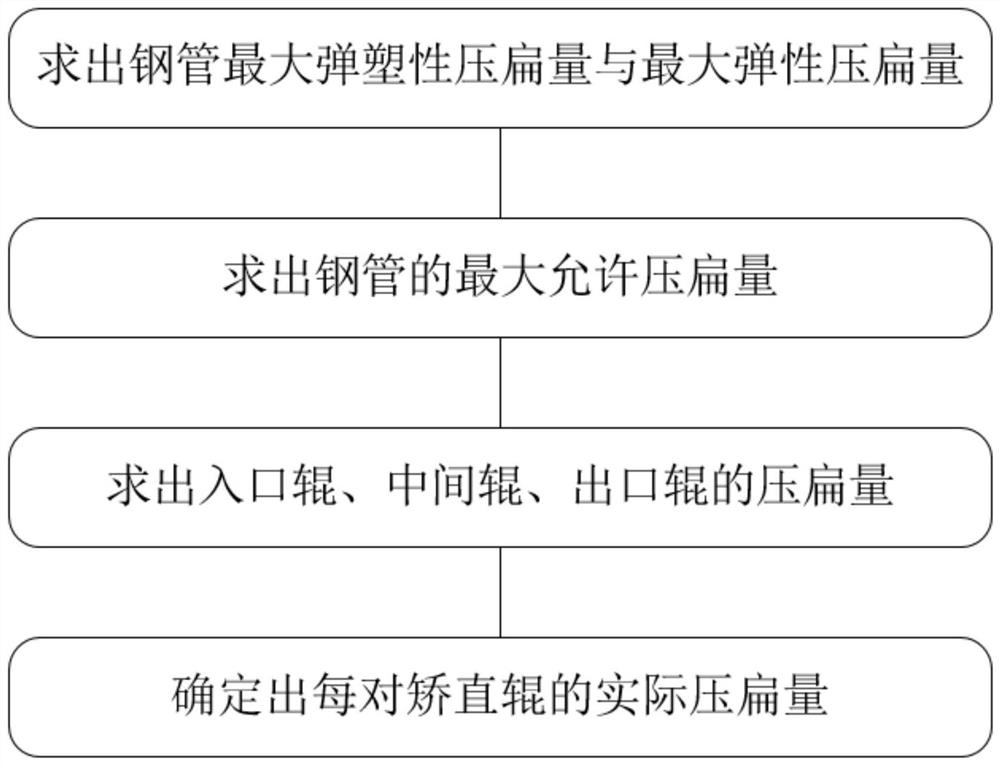

Method used

Image

Examples

Embodiment 1

[0039] The method for determining the flattening amount and distribution ratio of each pair of straightening rollers during the straightening process of large-diameter seamless steel pipe φ530*16 is as follows:

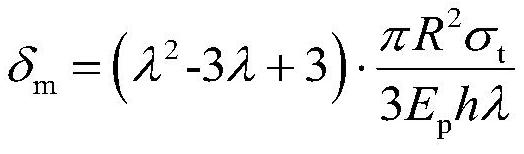

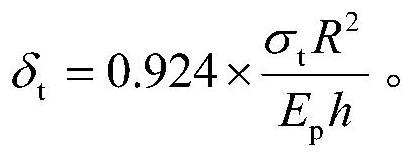

[0040] Firstly, the inner and outer diameter ratio of the steel pipe to be straightened is λ=0.955, the average section radius R=265mm, and the yield strength σ t =345MPa, elastic modulus E=206GPa, Poisson’s ratio μ=0.27 and other relevant parameters input the maximum elastic-plastic flattening amount δ m and the maximum elastic flattening amount δ t Solve the program to obtain the maximum elastoplastic flattening amount δ of the steel pipe m =7.85mm, the maximum elastic crushing amount δ t =6.11mm;

[0041] Then, call the corresponding formula in the maximum allowable flattening amount estimation table of the multi-roller straightening production practice database of steel pipes with different wall thicknesses to obtain the maximum allowable flattening amount of s...

Embodiment 2

[0045] The flattening amount and distribution ratio of each pair of straightening rollers during the straightening process of large-diameter seamless steel pipe φ920*60 are as follows:

[0046] Similarly, firstly, the inner and outer diameter ratio of the steel pipe to be straightened is λ=0.87, the average section radius R=430mm, and the yield strength σ t =785MPa, elastic modulus E=211GPa, Poisson’s ratio μ=0.27 and other relevant parameters input the maximum elastic-plastic flattening amount δ m and the maximum elastic flattening amount δ t Solve the program to obtain the maximum elastoplastic flattening amount δ of the steel pipe m =14.69mm, and the maximum elastic crushing amount δ t =9.82mm;

[0047] Then, call the corresponding formula in the maximum allowable flattening amount estimation table of the multi-roller straightening production practice database of steel pipes with different wall thicknesses to obtain the maximum allowable flattening amount of steel pipes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com