Sintering device of loose body optical fiber prefabricated rod

An optical fiber preform and sintering device technology, which is applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problems of uneven length, non-concentricity, failure of heating elements, etc., so as to reduce the rise of loss, improve concentricity, and ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

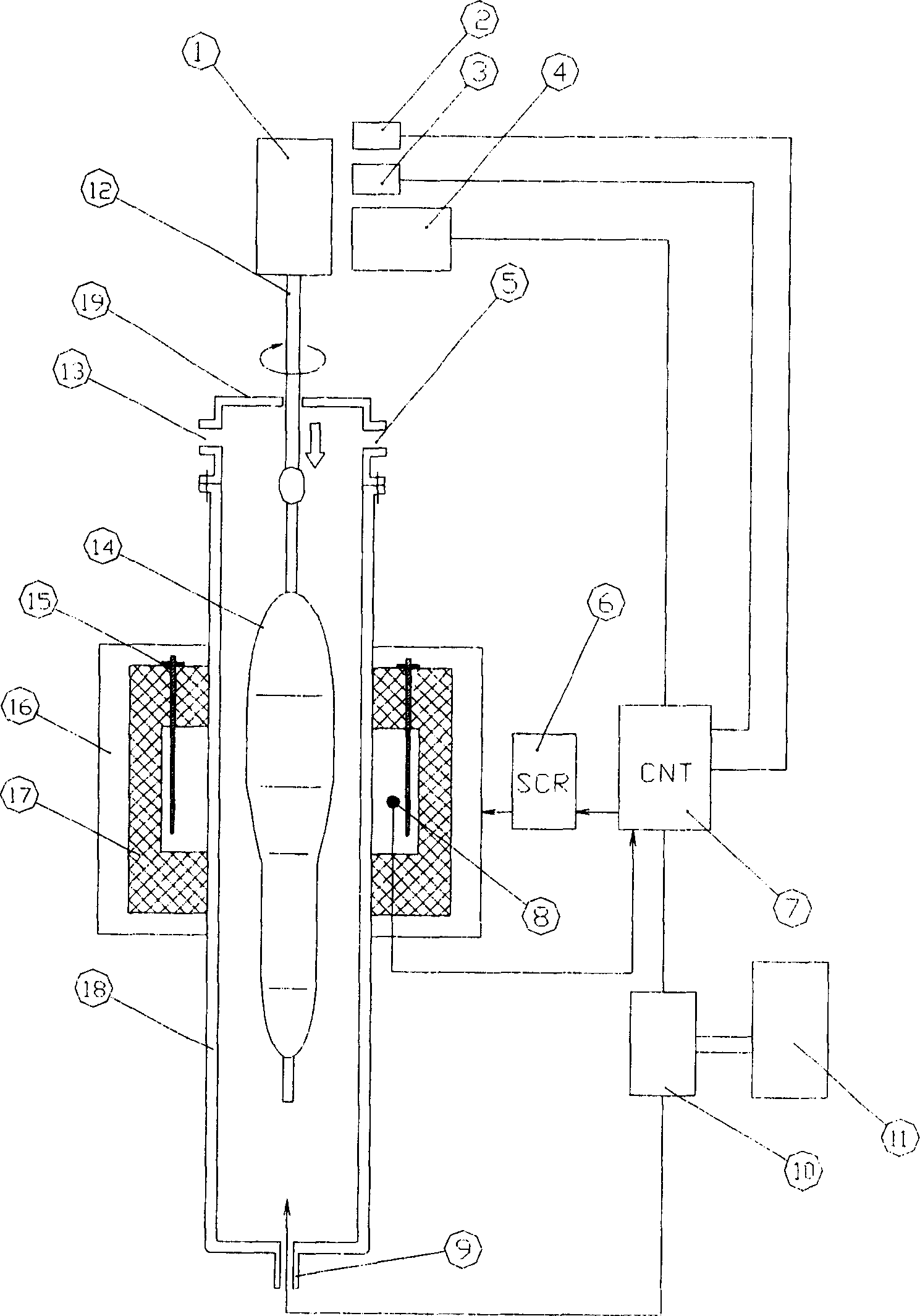

[0044]The soot preform 14 after external deposition is vertically suspended on the hanging rod 12 of the sintering tower, and the soot preform is slowly put into the sintering tube 18 through the lifting and translation of the servo motor 1; into the sintering tube, and placed on the sintering area of the heating device, cover the upper part of the sintering tube with a cover 19 to form a relatively airtight sintering atmosphere; the control device 7 controls the heating element 15 through the electric heater driving part When the temperature rises to 1100°C, gas such as 0.35 splm chlorine and 35 slpm helium is introduced into the sintered tube from the gas supply part 11 for dehydration. The proportion of gas is controlled at 1%; the dehydration time is 1 hour, and after the end, the electric heater driving part 6 controls the heating element 15 to raise the furnace temperature to 1500 °C; the control device 7 passes the position sensing device 3 and the speed sensing device...

specific example 2

[0046] The soot preform 14 after external deposition is vertically suspended on the hanging rod 12 of the sintering tower, and the soot preform is slowly put into the sintering tube 18 through the lifting and translation of the servo motor 1; into the sintering tube, and placed on the sintering area of the heating device, cover the upper part of the sintering tube with a cover 19 to form a relatively airtight sintering atmosphere; the control device 7 controls the heating element 15 through the electric heater driving part When the temperature rises to 1200°C, gas such as 0.6 splm chlorine and 25 slpm helium is introduced into the sintered tube from the gas supply part 11 for dehydration. The proportion of gas is controlled at 2.3%; the dehydration time is 0.75 hours, and after the end, the electric heater driving part 6 controls the heating element 15 to raise the furnace temperature to 1550 °C; the control device 7 passes the position sensing device 3 and the speed sensing ...

specific example 3

[0048] The soot preform 14 after external deposition is vertically suspended on the hanging rod 12 of the sintering tower, and the soot preform is slowly put into the sintering tube 18 through the lifting and translation of the servo motor 1; into the sintering tube, and placed on the sintering area of the heating device, cover the upper part of the sintering tube with a cover 19 to form a relatively airtight sintering atmosphere; the control device 7 controls the heating element 15 through the electric heater driving part When the temperature rises to 1200°C, gas such as 10 splm chlorine and 20 slpm helium is introduced into the sintered tube from the gas supply part 11 for dehydration. The ratio of dehydration is controlled at 4.7%; the dehydration time is 0.5 hours, and after the end, the electric heater driving part 6 controls the heating element 15 to raise the furnace temperature to 1550 ° C; the control device 7 is controlled by the position sensing device 3 and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com