Production method of corrosion-resistant and wear-resistant stainless steel hfw welded pipe with an outer diameter of 108-660.4mm

A production method, stainless steel technology, applied to pipeline systems, welding equipment, tubular objects, etc., can solve the problems of carbon steel being easy to corrode, easy to corrode, and short service life, and achieve cost saving, good corrosion resistance, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

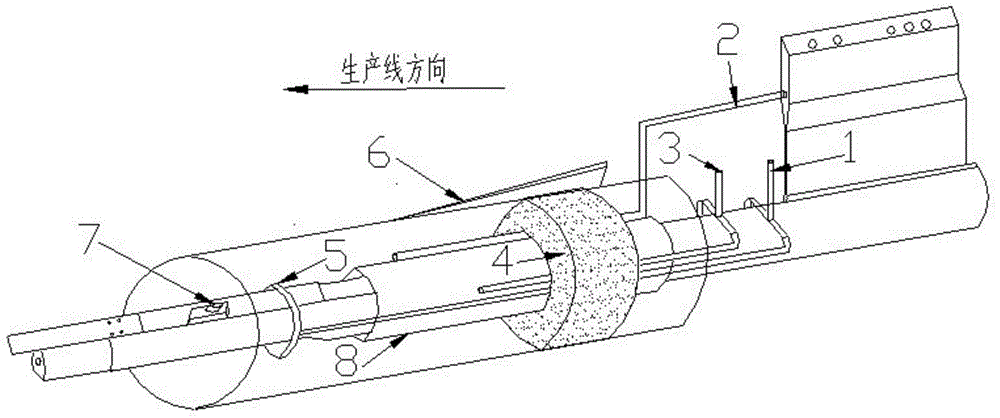

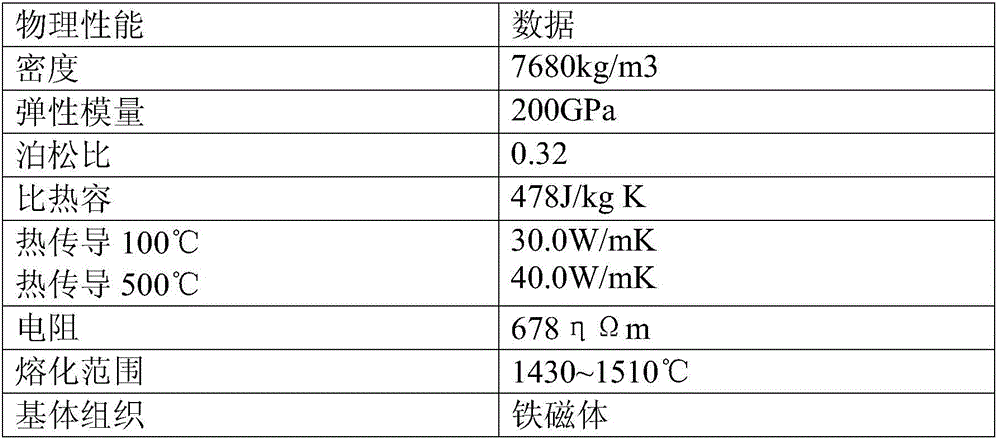

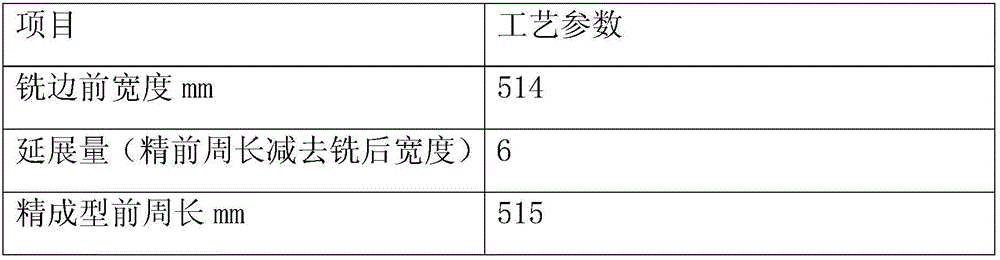

[0023] The production method of the corrosion-resistant and wear-resistant stainless steel HFW welded pipe with an outer diameter of 108 to 660.4 mm of the present invention is based on the production process of ordinary carbon steel, by controlling the sizing equipment, the parameters of the forming process, the high-frequency welding and the intermediate-frequency heat treatment temperature, and at the same time When the steel pipe is welded, the protective gas is introduced through the high-frequency straight seam welded pipe inner water curtain argon comprehensive welding protection device to protect the welding point and improve the welding quality. In addition, the geometric dimension accuracy of the steel pipe is improved, the outer diameter accuracy reaches ±0.2mm, and the straightness reaches 0.2mm / m. By improving the inner burr tool that goes deep into the middle of the pipe body, the shielding gas is brought into the lumen to protect the welding point and complete th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com