1*19 structure steel wire rope and preparation method thereof

A steel wire rope and steel wire technology, which is applied in the field of steel wire rope, can solve problems such as deep reduction and failure to meet customer needs, and achieve the effect of improving ellipticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for preparing a 1×19 structural steel wire rope, and the specific steps are as follows:

[0025] Step 1: select a smooth steel wire with a diameter of 1.60mm, and draw the 1.60mm smooth steel wire through a hot-dip galvanizing process to preferred monofilaments with a diameter of 0.35mm and 0.325mm.

[0026] Among them, the composition and weight percentage of the steel monofilament are: the content of carbon is 0.3% to 1.15%, the content of manganese is 0.1% to 1.1%, the content of silicon is 0.1% to 0.9%, and the content of sulfur and phosphorus does not exceed 0.15%, the chromium content is 0.2% to 0.4%, the copper content is 0.2%, and the others are iron.

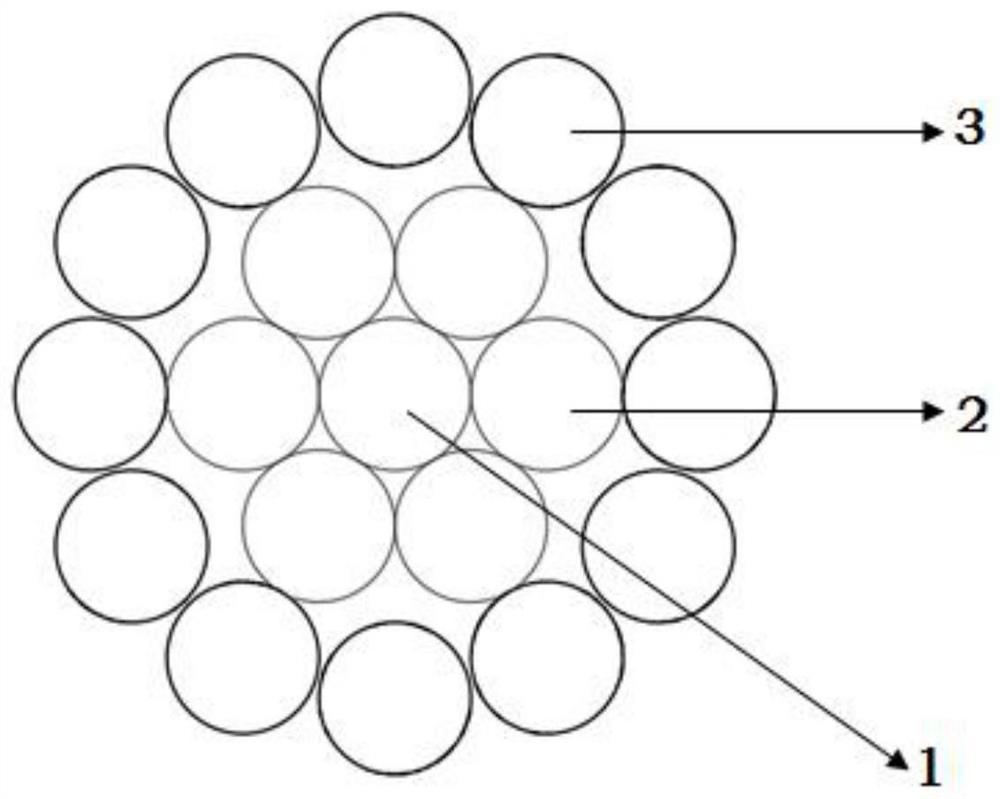

[0027] Step 2, select a monofilament with a diameter of 0.35mm as the first steel wire monofilament 1, select a monofilament with a diameter of 0.325mm as the second steel monofilament 2; combine 1 first steel monofilament 1 with 6 second steel wires The monofilament 2 is placed...

Embodiment 2

[0037] This implementation discloses a 1×19 structural steel wire rope, such as figure 1 As shown, it is prepared by using the preparation method of the 1×19 structural steel wire rope in Example 1.

[0038] Specifically, the 1×19 structural steel wire rope includes 1 first steel monofilament 1 , 6 second steel monofilaments 2 and 12 third steel monofilaments 3 .

[0039] Among them, 6 second steel monofilaments 2 are evenly distributed on the peripheral side of the first steel monofilament 1 to form a core strand structural strand; 12 third steel monofilaments 3 are evenly distributed on the periphery of the core structural strand side.

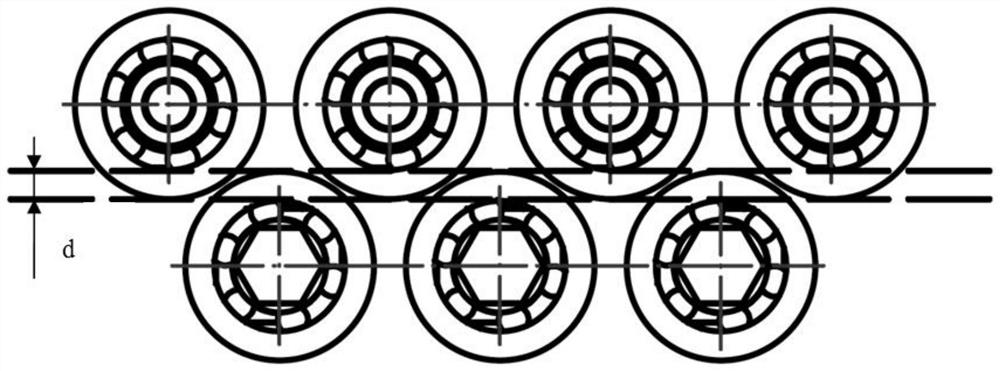

[0040] The experimental data shows that the 1×19-Φ1.59mm galvanized steel wire rope prepared in Example 1 has an ellipticity of 0.04 when the thickness of the steel wire rope is 1.58-1.62, and the ellipticity of the steel wire rope can be effectively controlled at 2.5% of the thickness of the steel wire rope within.

[0041] In the descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com