Production method of wood door

A production method and technology of wooden doors, applied in wood treatment, wood heat treatment, wood processing equipment, etc., can solve the problems of poor yield and quality of wooden door processing, and achieve improved surface quality, convenient size control, surface anti-corrosion and painting effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

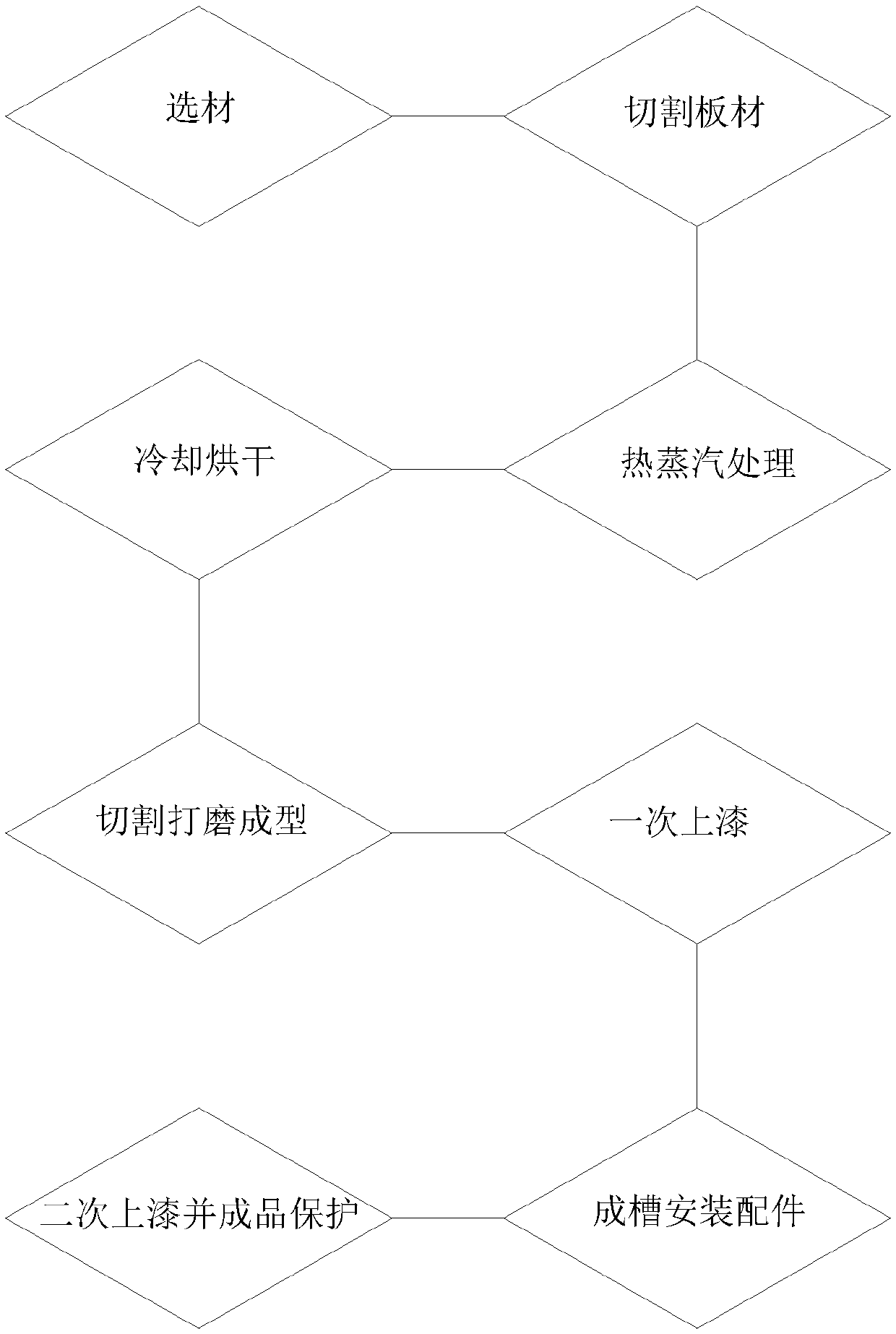

Image

Examples

Embodiment 1

[0036] A method for producing a wooden door, comprising the steps of:

[0037] Step 1, material selection, surface detection of the boards for the production of wooden doors;

[0038] Step 2: Cut the board according to the size of the door panel, cut it into an assembled panel, and splice the assembled panel into a pre-processed door panel according to the texture, the size of the pre-processed door panel is larger than the size of the formed door panel; and draw the contour line of the formed door panel on the pre-processed door panel;

[0039] Step 3. Perform hot steam treatment on the pre-processed door panel for 3 hours;

[0040] Step 4, airtightly cool the pre-processed door panel naturally, and let it stand for 2 days;

[0041] Step 5. Dry the pre-processed door panel and let it stand for 2 days;

[0042] Step 6. Carry out skinning and edge cutting on the surface of the pre-processed door panel, and polish the surface and edge to the size of the door panel;

[0043] S...

Embodiment 2

[0047] Embodiment two: a kind of production method of wooden door, comprises the steps:

[0048] Step 1, material selection, surface detection of the boards for the production of wooden doors;

[0049] Step 2: Cut the board according to the size of the door panel, cut it into an assembled panel, and splice the assembled panel into a pre-processed door panel according to the texture, the size of the pre-processed door panel is larger than the size of the formed door panel; and draw the contour line of the formed door panel on the pre-processed door panel;

[0050] Step 3. Perform hot steam treatment on the pre-processed door panel for 6 hours;

[0051] Step 4. Airtightly cool the pre-processed door panel and let it stand for 3 days;

[0052] Step 5. Dry the pre-processed door panel and let it stand for 2 days;

[0053] Step 6. Carry out skinning and edge cutting on the surface of the pre-processed door panel, and polish the surface and edge to the size of the door panel;

[...

Embodiment 3

[0059] A method for producing a wooden door, comprising the steps of:

[0060] Step 1, material selection, surface detection of the boards for the production of wooden doors;

[0061] Step 2: Cut the board according to the size of the door panel, cut it into an assembled panel, and splice the assembled panel into a pre-processed door panel according to the texture, the size of the pre-processed door panel is larger than the size of the formed door panel; and draw the contour line of the formed door panel on the pre-processed door panel;

[0062] Step 3: Carry out hot steam treatment on the pre-processed door panel, and the hot steam treatment is 4 hours;

[0063] Step 4. Airtightly cool the pre-processed door panel and let it stand for 3 days;

[0064] Step 5. Dry the pre-processed door panel and let it stand for 3 days;

[0065] Step 6. Carry out skinning and edge cutting on the surface of the pre-processed door panel, and polish the surface and edge to the size of the door p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com