Multi-row hole building block production device and multi-row hole building block production method

A production device and block technology, applied in the direction of supply device, ceramic molding machine, manufacturing tools, etc., can solve the problems of block production yield decline, damage to the hole structure, increase production costs, etc., to reduce risk costs and improve heat preservation Thermal insulation performance, good compression effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

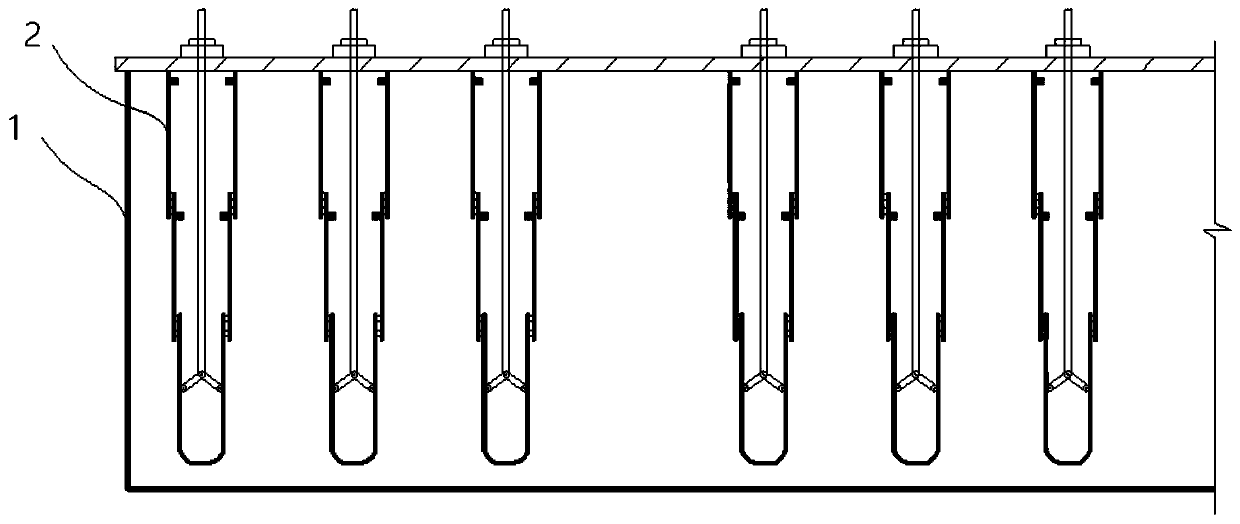

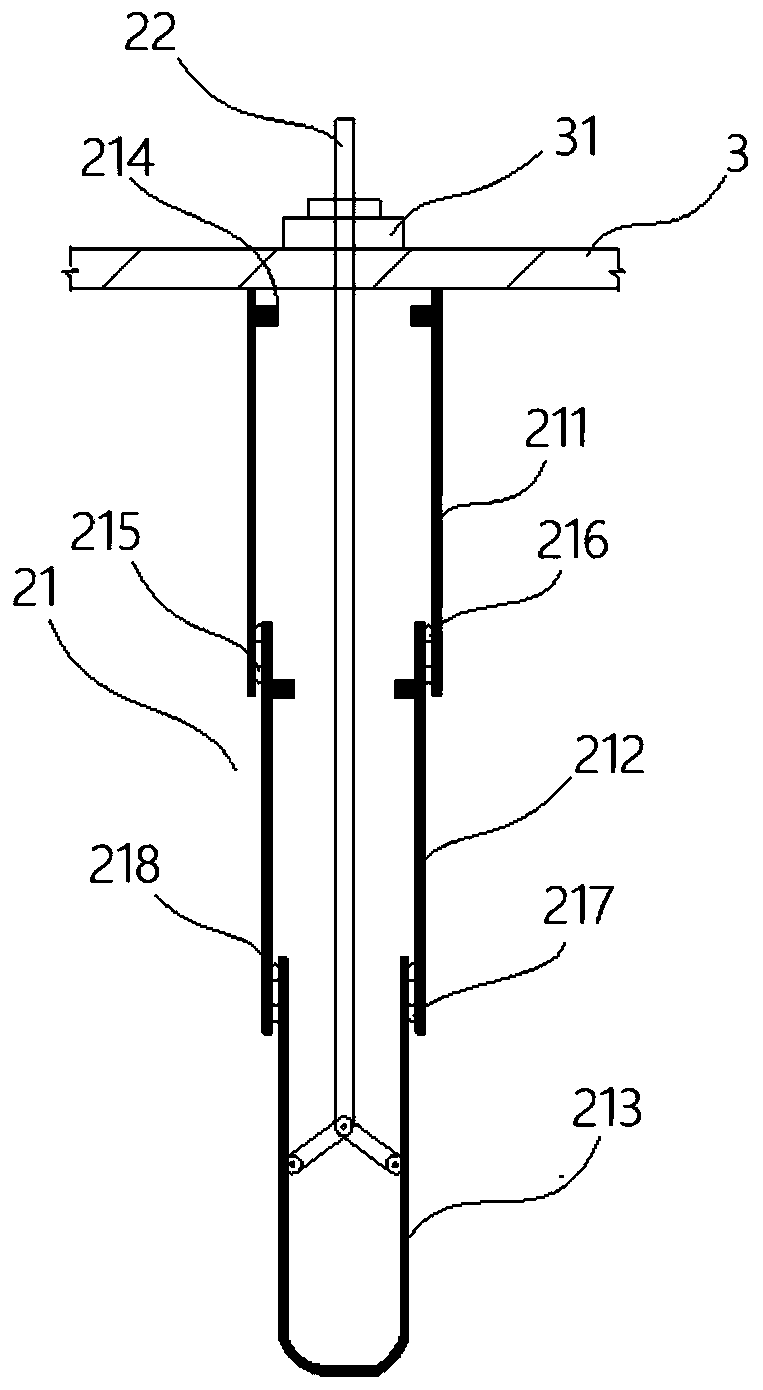

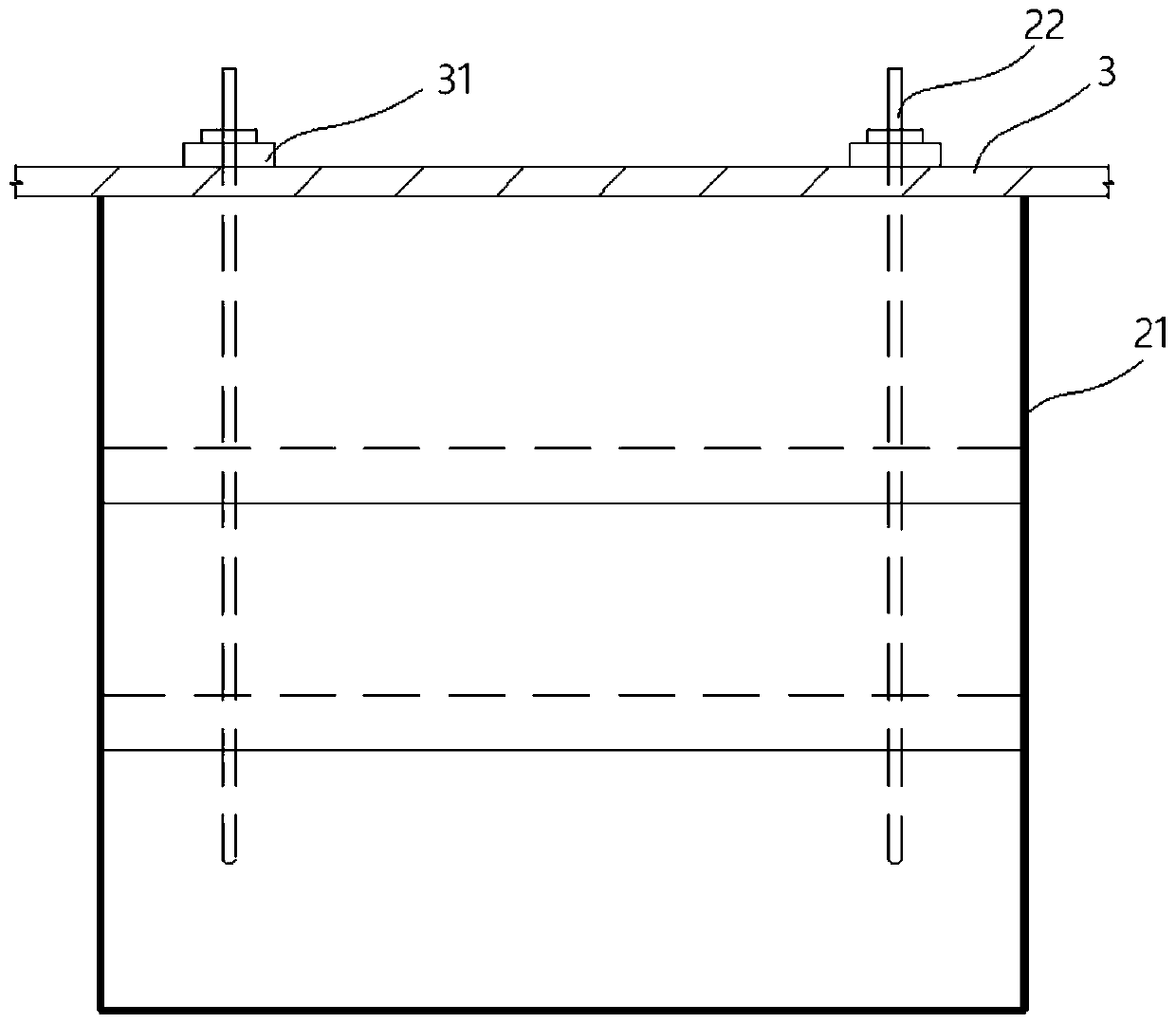

[0056] Such as Figure 1-Figure 4 As shown, a multi-row hole block production device disclosed in this embodiment includes a mold frame 1 and a mold column assembly 2, wherein, in order to facilitate form removal, the mold frame 1 is surrounded by a plurality of plate-like structures, and many The joints of the two plate structures are fixed by a hinge device, so that the mold frame can be easily disassembled, and the hinge device can be a detachable hinge or other fixing devices that are easy to disassemble. There is a molding cavity inside the mold frame 1, and an opening is provided on the upper surface of the molding cavity, through which the steam-pressurized concrete slurry can be injected into the molding cavity; multiple mold column assemblies 2 can be inserted into the molding cavity along the opening Inside, when the concrete slurry is injected into the molding cavity, the mold column assembly 2 forms a space in the molding cavity, and the concrete slurry avoids the ...

Embodiment 2

[0077] Such as Figure 6As shown, this embodiment is basically the same as the technical solution disclosed in Embodiment 1, the difference is that in this embodiment, the mold column body 21 is a foam that can melt or melt at a certain temperature, and the foam can be pulled out from the pin 22. Break away from pin 22 when leaving. During the production process of the multi-row hole block, first fix the foamed plastic on the pin 22 and fix it in the forming cavity, pour concrete slurry into the forming cavity, so that the concrete slurry forms an escape at the foamed plastic, and the concrete is After the initial setting of the slurry, the pin 22 is first pulled out, the main body of the mold column remains in the mold cavity, and then the mold is removed, and the initial setting concrete slurry is steamed at high temperature. During the steaming process, the main body of the mold column melts or melts, and It can be attached to the inner wall of the mold cavity to form a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com