Reinforced guide plate production process

A production process and deflector technology, applied in the field of reinforced deflector production technology, can solve the problems of restricting the development of lightweight rail transit, heavy weight, etc., and achieve structural diversity, weight reduction, and shape enrichment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

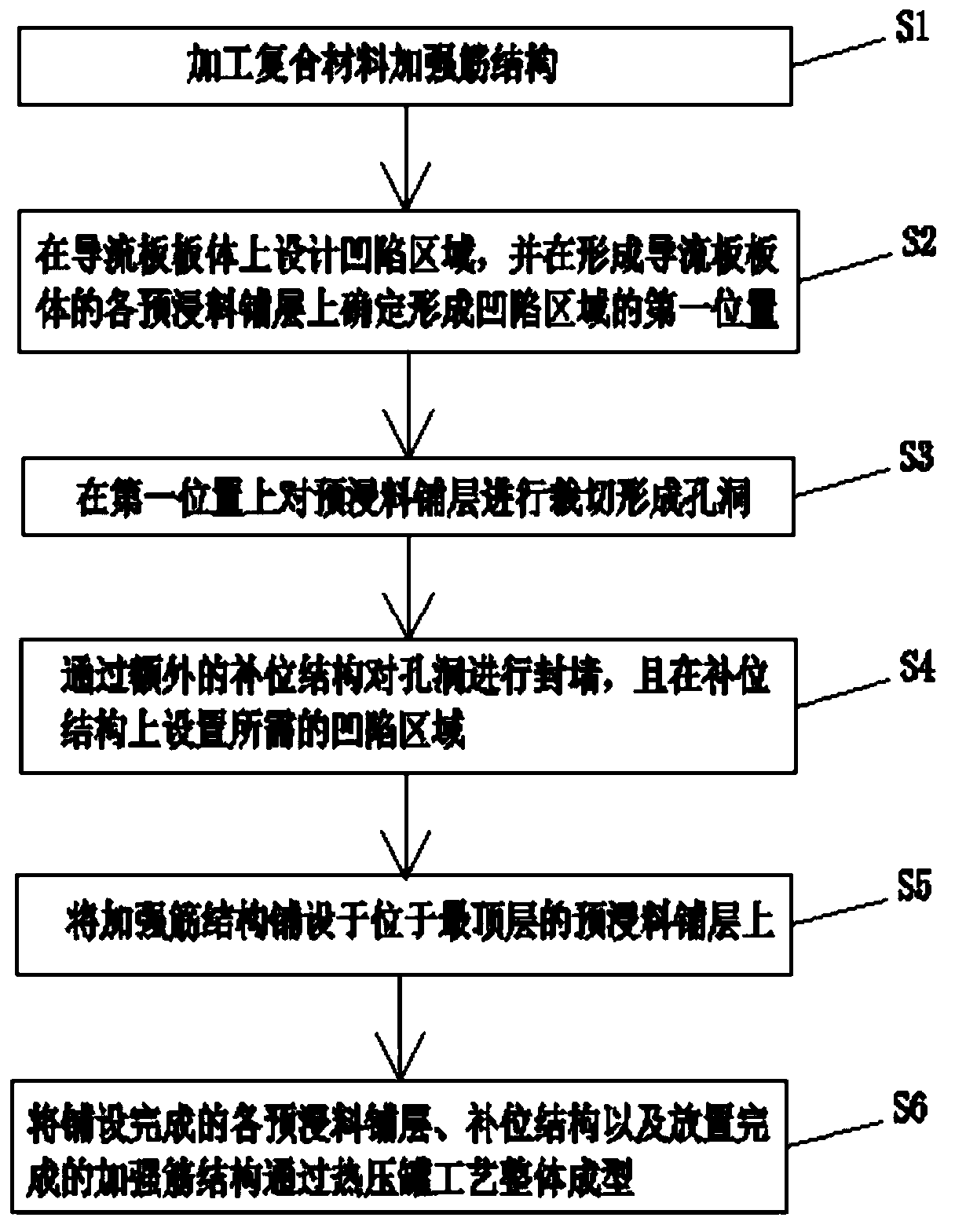

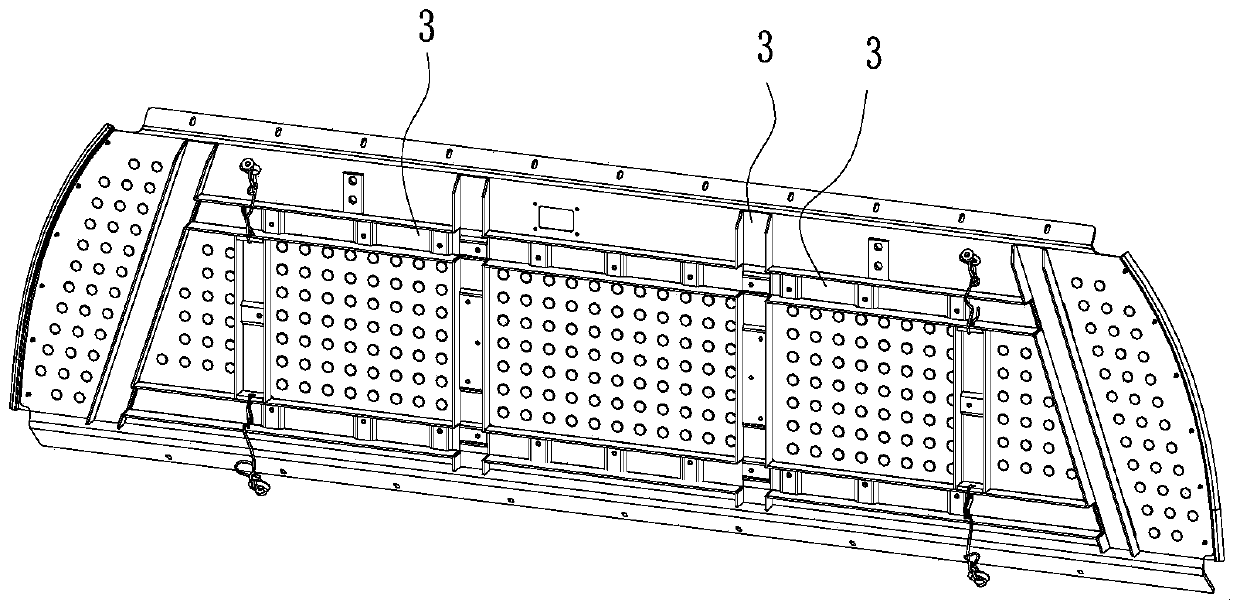

[0043] An enhanced deflector production process, such as figure 1 and 2 shown, including the following steps:

[0044] S1: Processing composite rib structure 3;

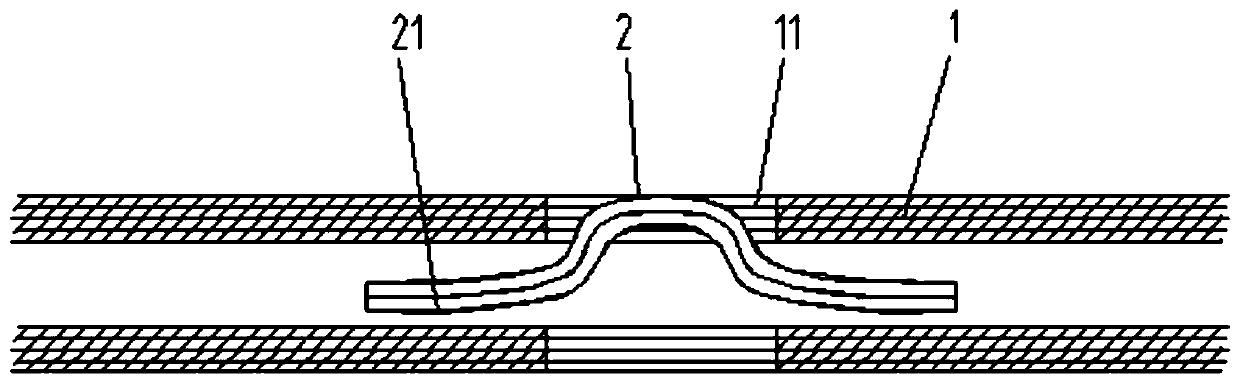

[0045] S2: Design a recessed area on the deflector body, and determine the first position for forming the recessed area on each prepreg layer 1 forming the deflector body;

[0046] S3: cutting the prepreg layer 1 at the first position to form holes 11;

[0047] S4: The hole 11 is blocked by the additional supplementary structure 2, and the required recessed area is set on the supplementary structure 2, such as image 3 shown;

[0048] S5: laying the rib structure 3 on the topmost prepreg layer 1;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com