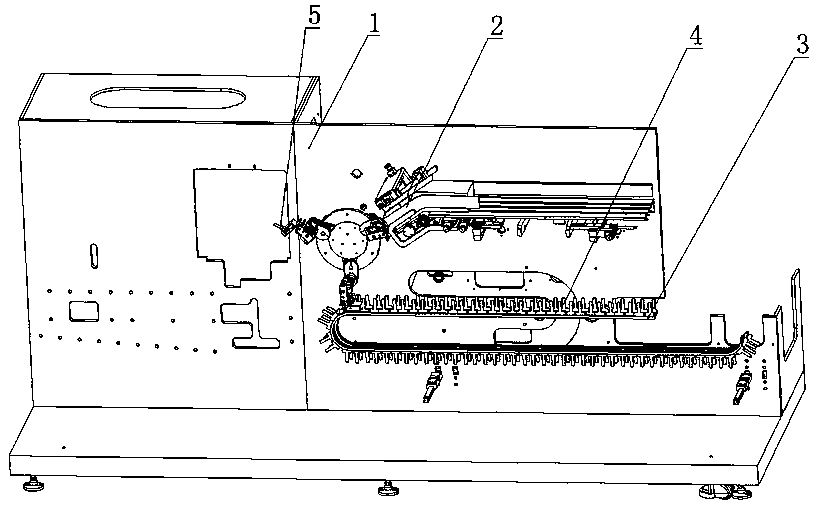

Box sucking and opening mechanism for packaging box

A technology of packaging boxes and racks, applied in packaging and other directions, can solve the problems of inability to absorb packaging boxes, inability to use automated production lines, or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

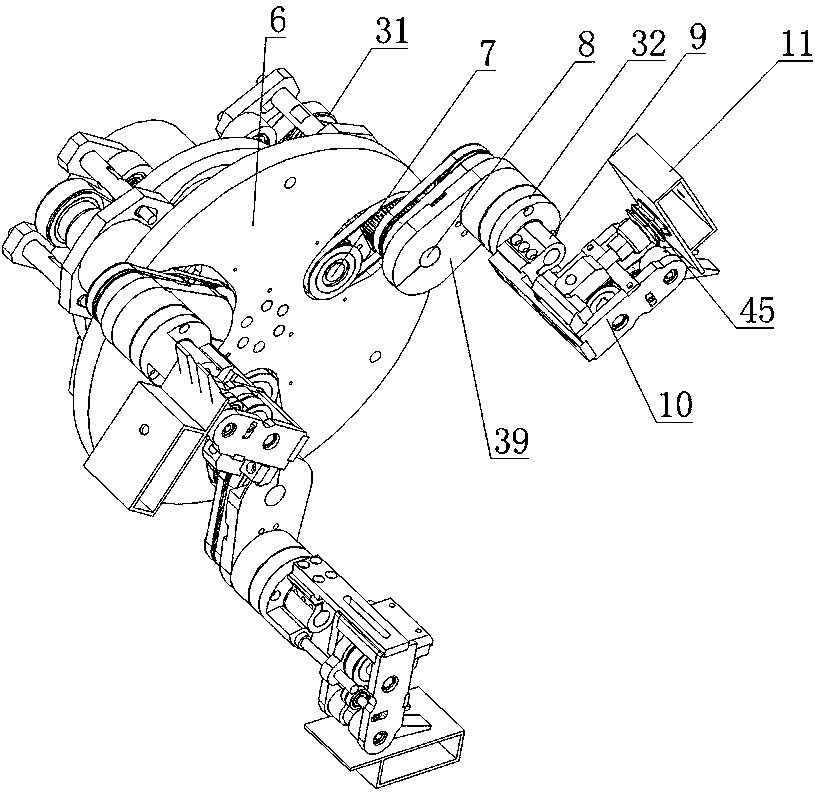

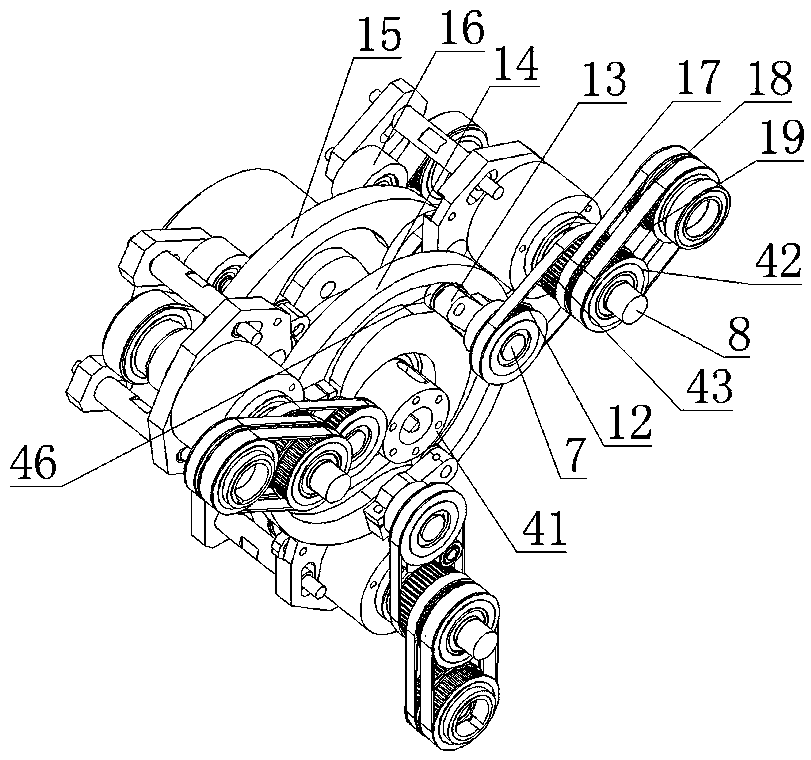

[0020] As shown in the figure, the suction box opening mechanism of this packaging box, a suction box opening mechanism of a packaging box, includes a frame 1, a power shaft 41, a rotating disk 6, a storage box frame 2, and the power shaft 41 It is installed on the frame 1 and driven by a driving device, which generally adopts a motor. The rotating disk 6 is fixedly installed on the power shaft 41, and rotates along with the power shaft 41. The first orbital disk 14 and the second orbital disk 15 are set on the power shaft 41, and are fixed on the power shaft 41. A fixed large synchronous wheel 30 is installed on the top, and the first orbital disk 14 and the second orbital disk 15 are provided with cam grooves 40, wherein the cam grooves 40 of the first orbital disk 14 are closed in the shape of a three-leaf plum blossom. Groove, the cam groove 40 of the second track disk 15 is a "❤" shaped closed groove, and the first rotating shaft 7 is equally divided on the rotating disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com