Wire laying method

A wire and wire collection technology, which is applied in the directions of cable laying equipment, transportation and packaging, thin material processing, etc., can solve the problems of messy construction site, interweaving wires, etc., to reduce labor intensity, increase adhesion, and improve wire collection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

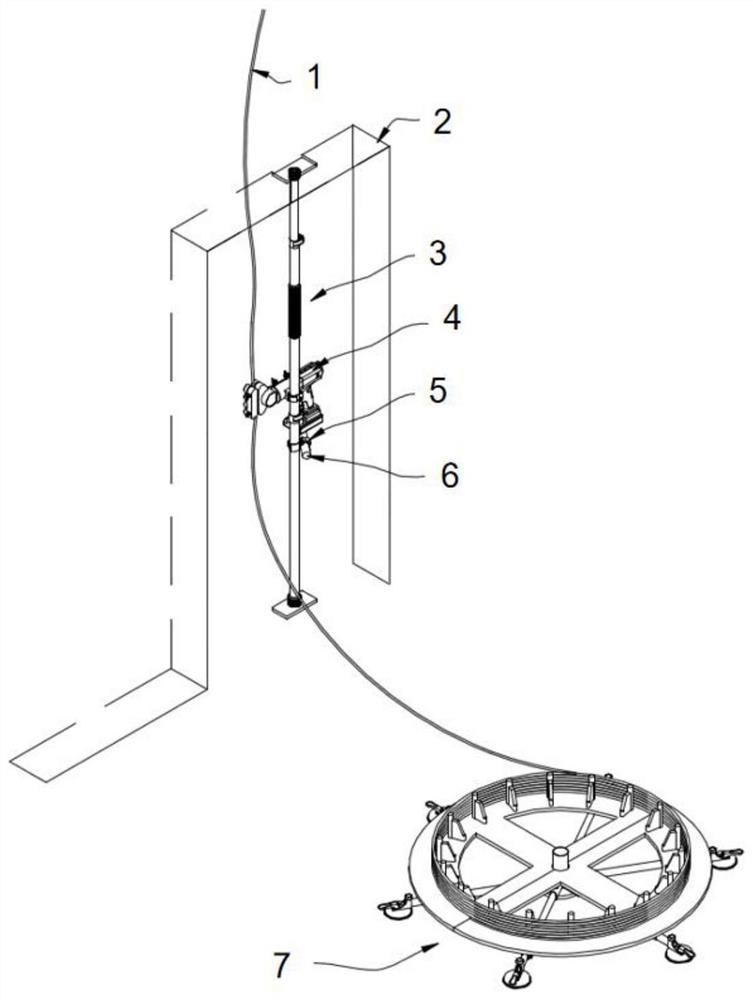

[0052] The wire laying and transmission method, the equipment mainly includes a telescopic rod 3, a wire laying and transmission device 4, and a wire coiling device. The wire laying and transmission device 4 is connected to the telescopic rod 3 through a connecting device. The rod is used as a support point to quickly erect the wire laying and transmission device 4 for wire transmission, and replace most of the manual work by machinery to realize the rapid transmission and collection of wires from the general power distribution room on the upper floor to the power distribution room on the next floor. Quickly collect wires through the coiling device to avoid interweaving of wires and messy construction site;

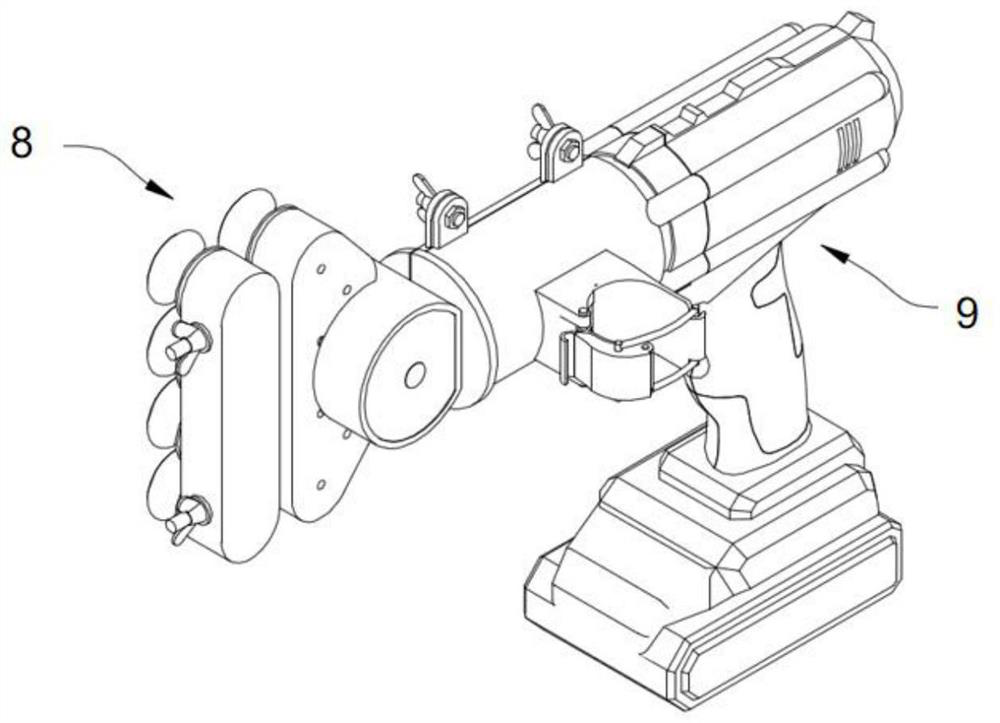

[0053] The wire laying and transmission device 4 includes a transmission mechanism 8 and a drive mechanism 9. The transmission mechanism 8 includes an output shaft 22, and one end of the output shaft 22 is connected with groups of bevel gear sets of different sizes, and th...

Embodiment 2

[0055] Based on embodiment 1, embodiment 2 further defines the wire laying transmission line device:

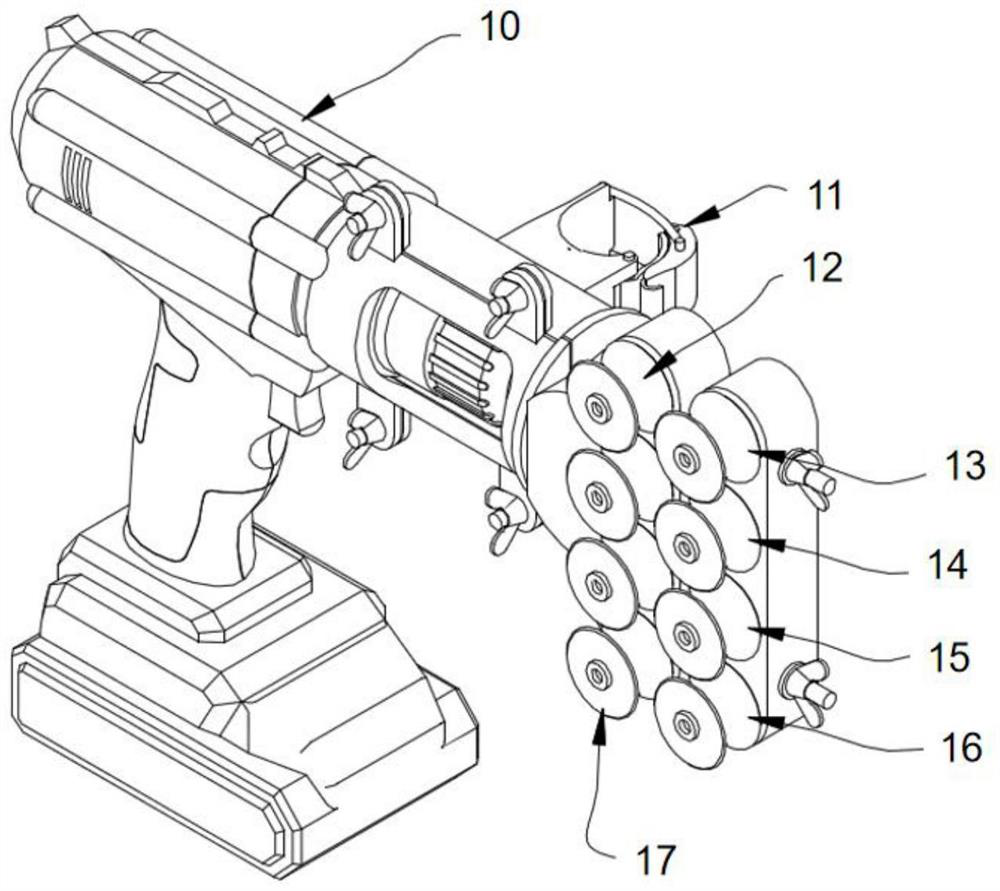

[0056] Further, in the above-mentioned wire laying and transmission method, the two sides of the main gear 30 are respectively meshed with gear one 31 and gear two 32, and gear three 33 and gear four 34 are meshed with gear one 31, and gear two 32 are meshed with gear two. Engagement has gear five 35 and gear six 36, and gear three 33, gear four 34, gear five 35 and gear six 36 connect drive wheel one 12, drive wheel two 28, drive wheel three 29 and drive wheel four 17 respectively, and drive Wheel one 12, driving wheel two 28, driving wheel three 29 and driving wheel four 17 rolling friction connections are pinch wheel one 13, pinch wheel two 14, pinch wheel three 15 and pinch wheel four 16.

[0057] Further, the above-mentioned wire laying and transmission method also includes a housing 26, the housing 26 mainly includes two parts, one part of the housing is connected with ...

Embodiment 3

[0065] Based on Embodiment 1 or Embodiment 2, Embodiment 3 further defines the structure of the telescopic rod:

[0066] Further, in the above-mentioned wire laying and transmission method, the telescopic rod 3 includes a plurality of rod bodies with gradually smaller diameters, which are divided into rod body one 43, rod body two 44 and rod body three 45 from bottom to top, and the plurality of rod bodies can be composed of telescoping structure.

[0067] Further, the above-mentioned wire laying and transmission method also includes a locking clip 47, the locking clip 47 is composed of a sleeve 50, a fastening bolt 54, a locking clip pin shaft 51 and a handle 53, wherein the sleeve 50- The side opening forms two parts on the left and right, wherein a part of the inner wall is connected with a connecting rod, and the other part is provided with a through hole at a position suitable for the connecting rod. Rotately connected with the handle 53, the side of the handle 53 close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com