A kind of urea-formaldehyde resin environmental protection filler for plywood

A technology of urea-formaldehyde resin and plywood, applied in adhesives, adhesive types, adhesive additives, etc., can solve problems such as limiting formaldehyde adsorption, bentonite without formaldehyde removal, and plywood degluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

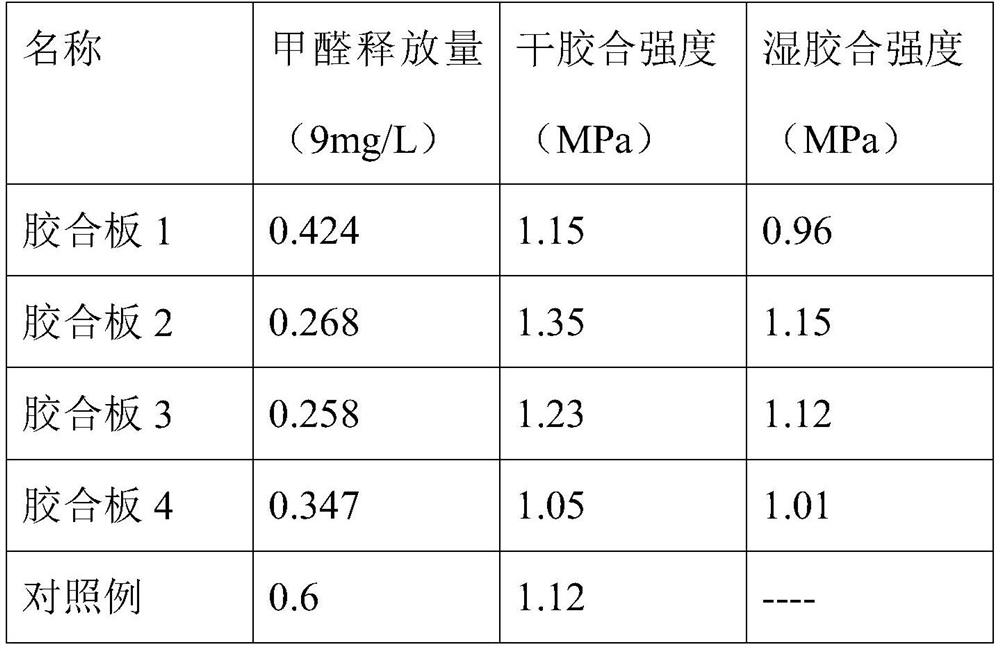

Examples

Embodiment 1

[0023] An environmentally friendly urea-formaldehyde resin filler for plywood, characterized in that it is formed by mixing the following materials in parts by weight: rice husk powder 10, wheat bran powder 10, flour 10, attapulgite 30, modified bovine bone powder 20, p-toluene Sulfonamide 3, antiaging agent AW 2, curing agent ammonium chloride 6, thickener sodium carboxymethyl cellulose 5, compatibilizer ABS-g-MAH 2.

[0024] The preparation method of described modified bovine bone powder is as follows:

[0025] (1) Degreased bovine bone meal 20, plant ash 3, polyisobutylene 2, methyl acrylate 3, glycerol 3, thiourea 2, polyquaternium-7 0.05, carboxymethyl cellulose 5, arachidonic acid 3, Sodium bicarbonate 0.1, ethylene glycol diglycidyl ether 2, emulsifier Z37A0.25, coupling agent KH500 0.5, distilled water 120;

[0026] (2) After crushing and sieving the defatted bovine bone powder, mix it with plant ash, carboxymethyl cellulose, polyisobutylene, glycerin, and thiourea at...

Embodiment 2

[0029] An environmentally friendly urea-formaldehyde resin filler for plywood, characterized in that it is formed by mixing the following materials in parts by weight: rice husk powder 15, wheat bran powder 15, flour 5, attapulgite 25, modified bovine bone powder 30, p-toluene Sulfonamide 3, antiaging agent AW 2, curing agent ammonium chloride 10, thickener sodium carboxymethylcellulose 6, compatibilizer EVA-g-MAH 2.

[0030] The preparation method of described modified bovine bone powder is as follows:

[0031] (1) Degreased bovine bone meal 20, plant ash 4, polyisobutylene 4, methyl acrylate 5, glycerol 3, thiourea 2, polyquaternium-7 0.05, carboxymethyl cellulose 5, arachidonic acid 3, Sodium bicarbonate 0.1, ethylene glycol diglycidyl ether 2, emulsifier Z37A0.30, coupling agent KH500 1, distilled water 120;

[0032] (2) After crushing and sieving the defatted bovine bone powder, mix it with plant ash, carboxymethyl cellulose, polyisobutylene, glycerin, and thiourea at a ...

Embodiment 3

[0035] An environmentally friendly urea-formaldehyde resin filler for plywood, characterized in that it is formed by mixing the following materials in parts by weight: rice husk powder 15, wheat bran powder 10, flour 10, attapulgite 20, modified bovine bone powder 30, p-toluene Sulfonamide 6, anti-aging agent AW 3, curing agent sodium carboxymethyl cellulose ammonium chloride 10, thickener 8, compatibilizer EVA-g-MAH 3.

[0036] The preparation method of described modified bovine bone powder is as follows:

[0037] (1) Degreased bovine bone meal 25, plant ash 4, polyisobutylene 2, methyl acrylate 5, glycerol 3, thiourea 2, polyquaternium-7 0.05, carboxymethyl cellulose 5, arachidonic acid 6, Sodium bicarbonate 0.15, ethylene glycol diglycidyl ether 2, emulsifier Z37A0.30, coupling agent KH500 1, distilled water 120;

[0038] (2) After crushing and sieving the defatted bovine bone powder, mix it with plant ash, carboxymethyl cellulose, polyisobutylene, glycerin, and thiourea a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com