Vanadium titano-magnetite smelting blast furnace yield improving technology

A vanadium titanomagnetite and blast furnace technology is applied in the field of vanadium titanomagnetite smelting blast furnace production increase, can solve the problems of hearth erosion, unfavorable cooling stave maintenance, increased blast volume and oxygen enrichment, etc. The effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make those skilled in the art more clear and clear the technical scheme of the present invention, the present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

[0030] A kind of vanadium-titanium-magnetite smelting blast furnace production raising technology provided by the present embodiment comprises the following steps:

[0031] Step 1: By evaluating each part of the feeding system, formulate the particle size standard of raw materials suitable for use in blast furnaces;

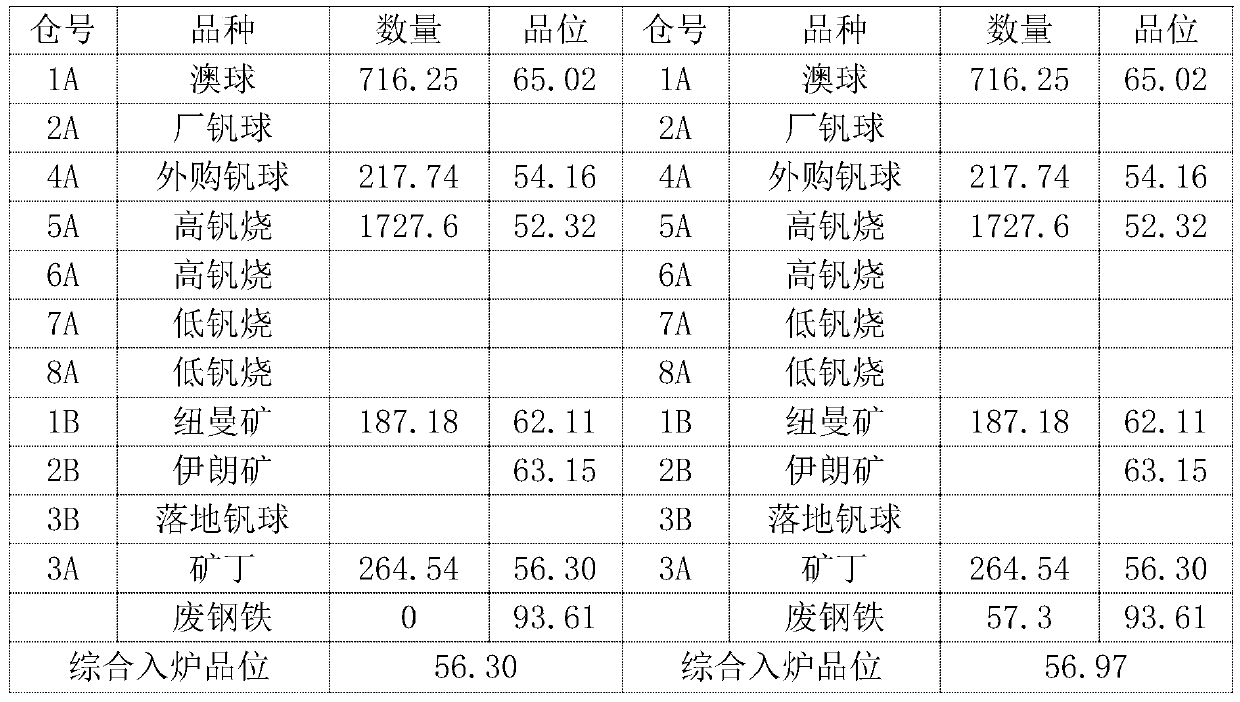

[0032] Step 2: Use raw ore and scrap iron and steel for loading under the trough;

[0033] Step 3: After the comprehensive grade is improved, the temperature of molten iron is appropriately increased to ensure sufficient heat in the hearth and maintain the smooth operation of the blast furnace;

[0034] Step 4: Increase the number of tapping times in front of the furnace by 1, fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com