Steel for tempering-free gear free of carbide bainite and production method of steel

A technology of bainite and carbide, which is applied in the field of gear steel, can solve the problems of high energy consumption in quenching and tempering process, difficulty in quenching heat treatment deformation control, etc., and achieve the effect of improving service life, reducing energy consumption and cost, and suppressing crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

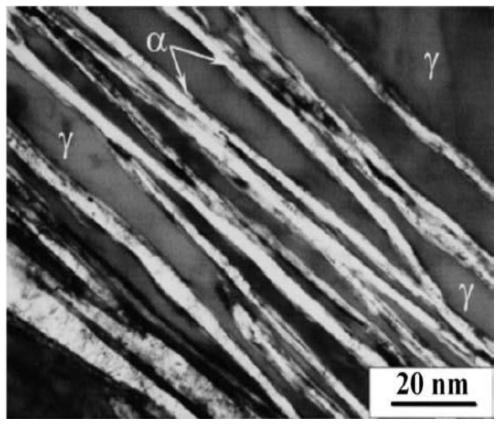

Image

Examples

Embodiment 1

[0029] No quenching and tempering gear steel 1 without carbide bainite, its chemical composition is calculated by weight percentage: C: 0.05wt%, Si: 0.78wt%, Mn: 1.50wt%, Al: 3.7wt%, P: 0.005wt%, S: 0.006wt%, Ni: 0.20wt%, Ti: 0.028wt%, and the rest are Fe and unavoidable impurities.

[0030] The production method of the above-mentioned carbide-free bainite-free gear steel 1, the method is smelted according to the above-mentioned chemical composition according to traditional smelting to obtain the self-strengthening gear steel 1 whose microstructure is carbide-free bainite, wherein,

[0031] 1) In the process of billet casting, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is 880°C, and the temperature is 4S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 850°C;

[0032] 2) After rolling, the finished product is in the slow coo...

Embodiment 2

[0035] No quenching and tempering gear steel 2 without carbide bainite, its chemical composition is calculated by weight percentage: C: 0.03wt%, Si: 0.73wt%, Mn: 1.38wt%, Al: 3.6wt%, P: 0.005wt%, S: 0.004wt%, Ni: 0.22wt%, Ti: 0.024wt%, and the rest are Fe and unavoidable impurities.

[0036] The production method of the above-mentioned carbide-free bainite-free gear steel 2, the method is smelted according to the above-mentioned chemical composition according to traditional smelting to obtain self-strengthening gear steel 2 whose microstructure is carbide-free bainite, wherein,

[0037] 1) During the billet casting process, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is 910°C, and the temperature is 4S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 800°C;

[0038] 2) After rolling, the finished product is in the slow coolin...

Embodiment 3

[0041] The non-tempered gear steel 3 without carbide bainite, its chemical composition is calculated by weight percentage: C: 0.03wt%, Si: 0.74wt%, Mn: 1.46wt%, Al: 3.4wt%, P: 0.007wt%, S: 0.005wt%, Ni: 0.15wt%, Ti: 0.026wt%, and the rest are Fe and unavoidable impurities.

[0042] The production method of the aforementioned carbide-free bainite-free quenched and tempered gear steel 3, the method is smelted according to the above-mentioned chemical composition according to traditional smelting to obtain self-reinforced gear steel 3 whose microstructure is carbide-free bainite, wherein,

[0043] 1) In the process of billet casting, controlled rolling and controlled cooling are carried out after being heated by the heating furnace: the temperature in the finishing rolling stage is 930°C, and the temperature is 4S -1 The deformation rate is the last 10% deformation rolling, and the final rolling temperature is 830°C;

[0044] 2) After rolling, the finished product is in the slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com