Electric control piston oil injection cooling system and working method thereof

An oil-injection cooling and piston technology, applied in the field of electronically controlled piston oil-injection cooling system, can solve the problems of ineffective use of the internal cooling oil cavity for cooling, insufficient oil cooling area, and inability to cool the bottom of the piston, so as to improve power performance and economy. performance, optimized cooling, smooth cold start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, by referring to the accompanying drawings, the embodiment of the present invention will be described in further detail through the description of the embodiments, in order to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and to help on its implementation.

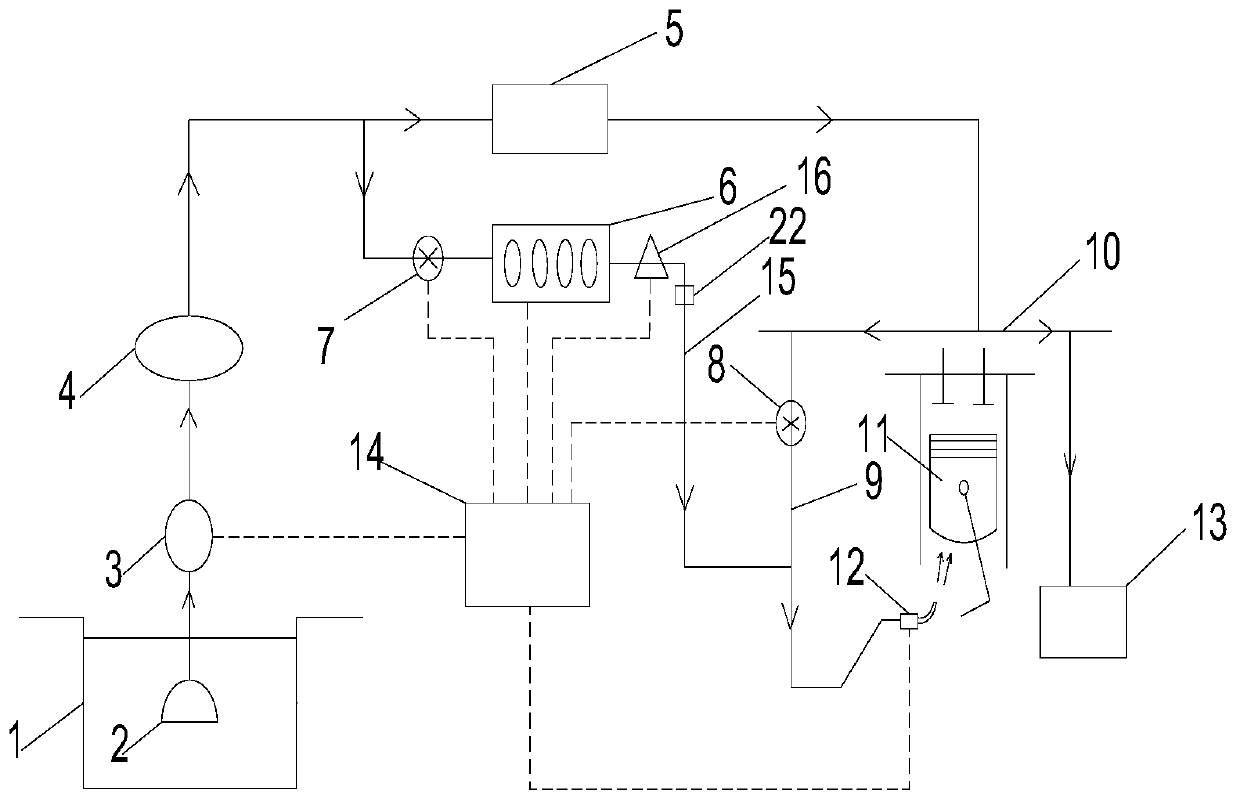

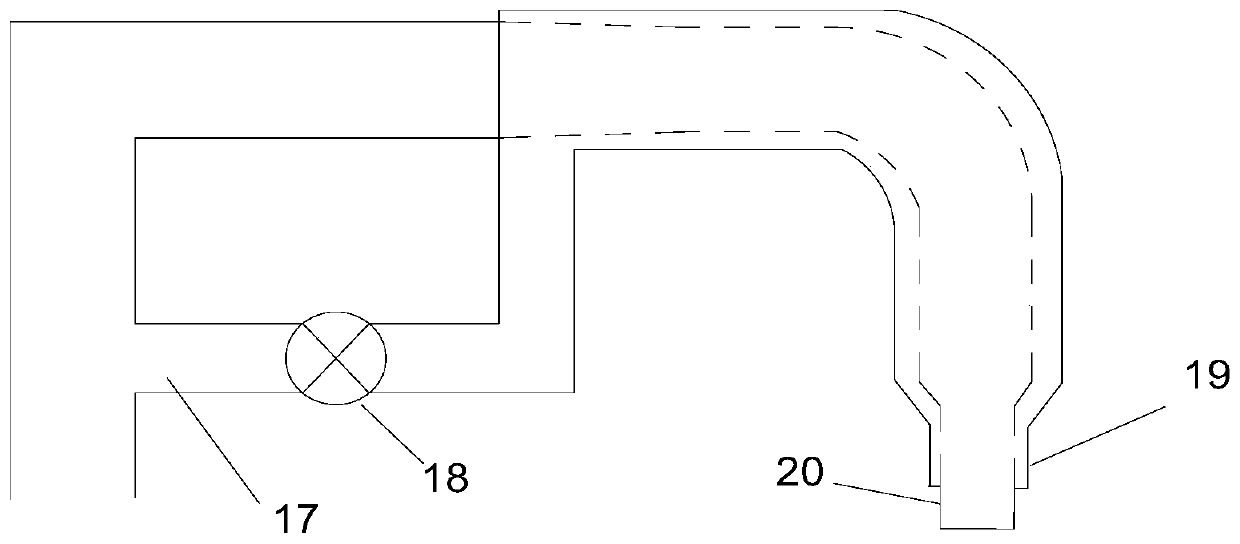

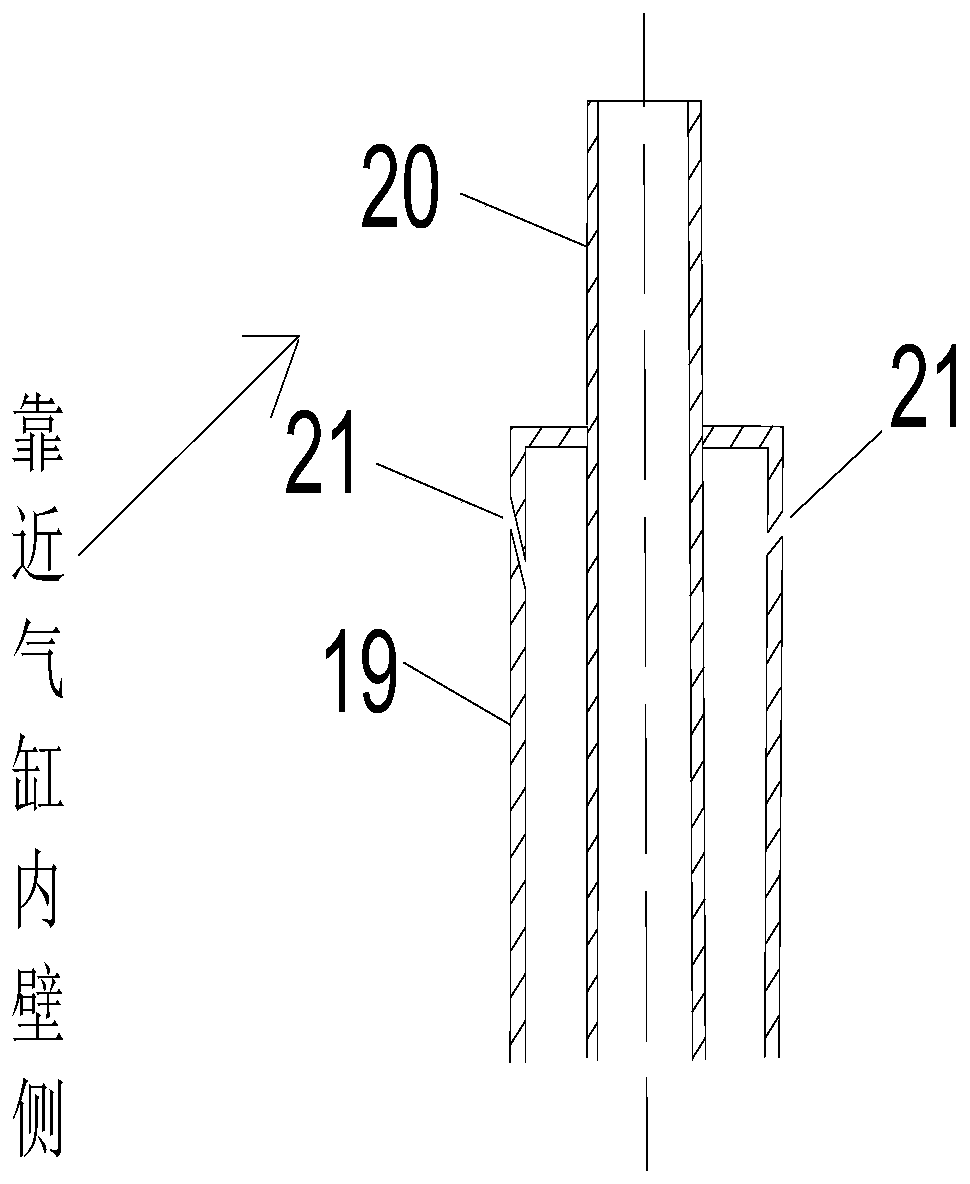

[0029] Such as figure 1 , the present invention provides an electronically controlled piston fuel injection cooling system, comprising a variable displacement electronically controlled oil pump 3, an oil injection nozzle 12, an oil filter 2 connected to a variable displacement electronically controlled oil pump 3, and a variable displacement electronically controlled machine The outlet of the oil pump 3 is connected to the oil filter 4, and the oil filter enters the main oil passage 10 through the oil cooler 5, and a heater connected to the inlet of the oil injector 12 is set between the oil filter 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com