Crane rotation buffer reversing valve and crane open type rotation brake control system

A technology of slewing buffer and crane, which is applied in the direction of cranes, multi-way valves, valve devices, etc., can solve the problems of pressure oil leakage, high sensitivity of hydraulic oil temperature, rising and rising to overload valve pressure, etc., so as to improve reliability , simple structure, good effect of pressure relief and pressure building speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

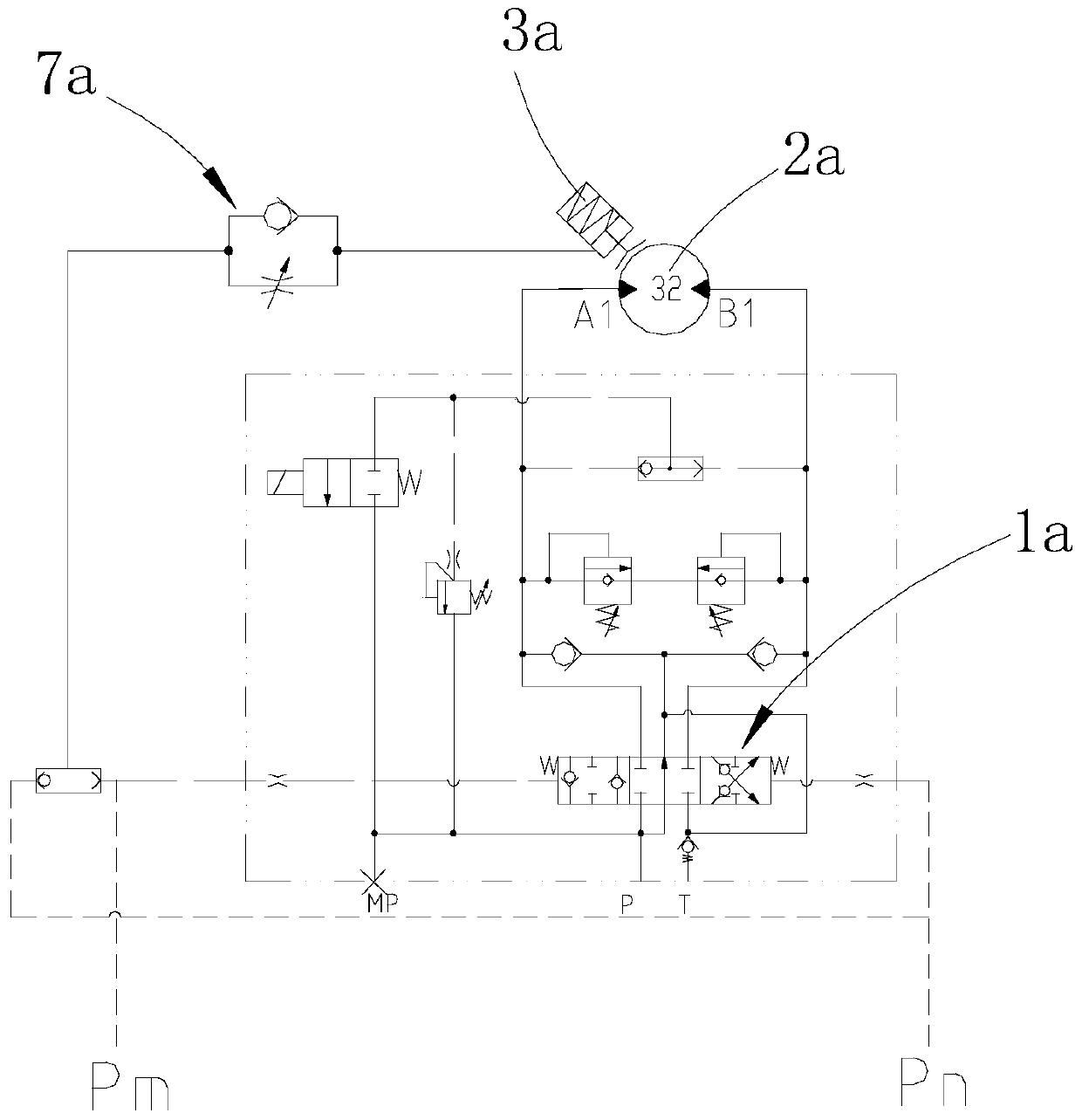

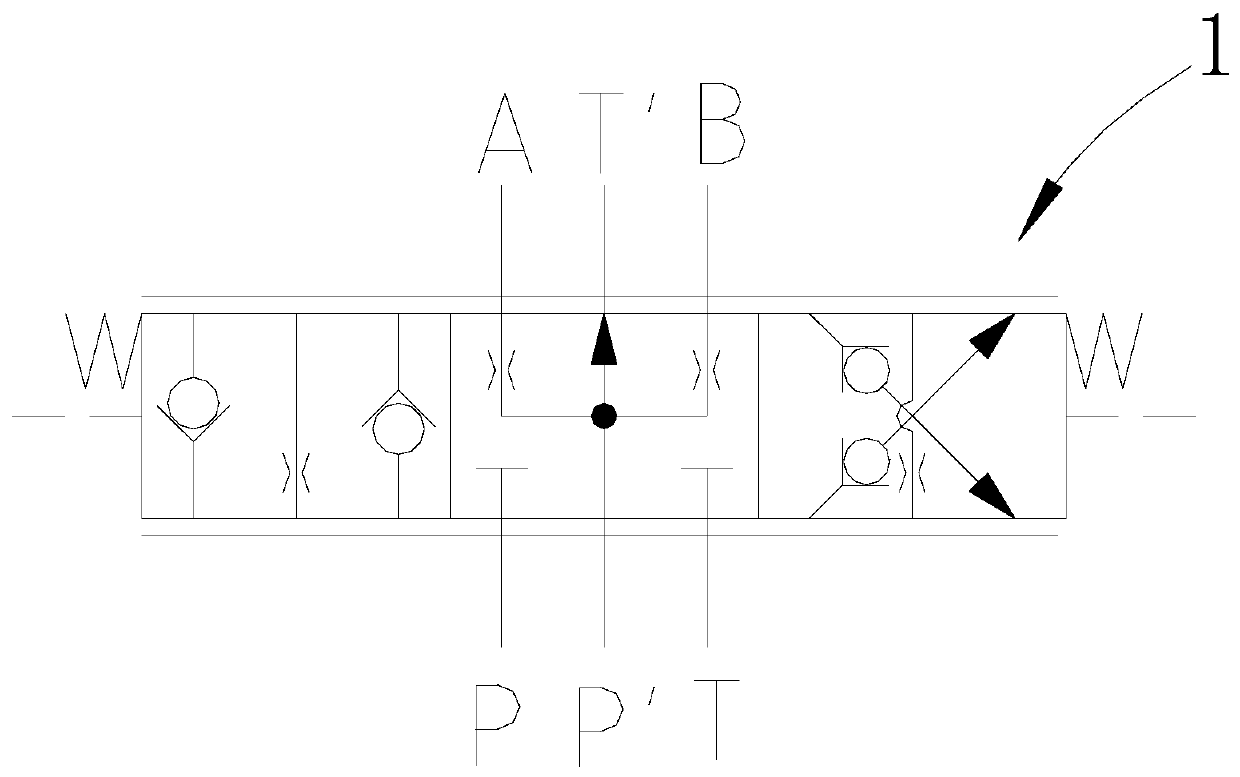

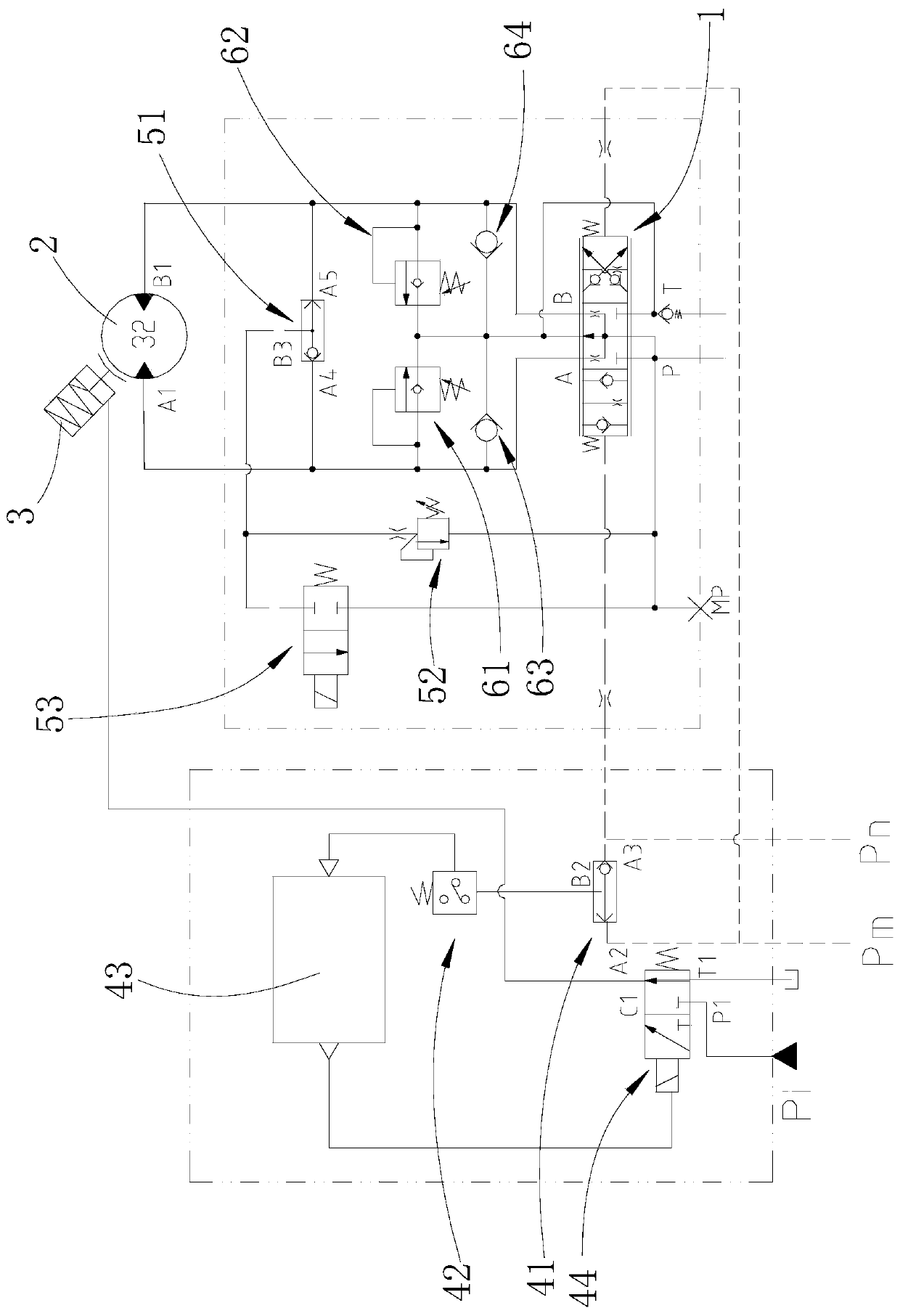

[0035] Such as Figures 2 to 3 shown

[0036]The crane slewing buffer reversing valve 1 is a three-position six-way valve. The crane slewing buffer reversing valve 1 has a first reversing port A, a second reversing port B, an oil inlet P, an oil return port T, a first The unloading port P' and the second unloading port T', the oil inlet P and the first unloading port P' are respectively connected to the rotary oil source, and the oil return port T and the second unloading port T' are respectively connected to the oil tank;

[0037] The crane slewing buffer reversing valve 1 has a neutral position, a first working position and a second working position. The unloading ports T' are respectively connected, and the passage between the first unloading port P' and the first reversing port A is a throttling passage (the aperture of the throttling passage is smaller than the aperture of the normal passage, and the flow rate of the throttling passage is smaller than that of the normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com